BEDIA MOTORENTECHNIK GMBH & CO. KG - Messen mit System und Leidenschaft

Germany

Manufacturer/ Producer

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

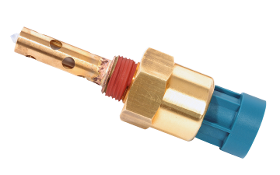

Areas of Application and Advantages BEDIA CLS 10 stands for special versions of our well-proven CLS 40 series for heavy duty applications. Currently, the BEDIA CLS 10 series includes a variety of sensors, which are compatible replacement parts for level switches from Cooper Standard and Robert Shaw which are obsolete nowadays – and this in well proven BEDIA quality. This also includes sensors with 2 complementary CMOS outputs. It should be emphasized that the water sensors with two complementary outputs can be operated with a supply voltage of 4.75 V DC – 32 V DC. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate (at a frequency of approx. 600 kHz). Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quoteAlthough we remain a medium-sized business, our many years of focusing our skills on the fields of fill level and temperature detection under harsh ambient conditions has allowed BEDIA to become proficient in providing solutions that meet the high demands posed by our clients in their entirety. Since the company was founded, we have been "in touch with the medium" through the use of reliable and innovative technologies, having completely dispensed with mechanically moving parts that are often prone to failure. We are a recognised partner to numerous manufacturers of engines, construction machinery, agricultural machinery, industrial vehicles, buses, aggregates and compressors. Moreover, our capacitive fill level sensors have been authorised by ten classification societies for use in a wide variety of marine applications. We also offer a range of voltage transformers that stand out thanks to their compact design and low quiescent current consumption.

Websites

Documents

Manufacturer/ Producer

Im Erlet 1

90518 Altdorf - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

Organisation

-

- Year established

- 1986

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Activities of BEDIA MOTORENTECHNIK GMBH & CO. KG

- Sensors

- Automotive cables

- Fluid level switches

- Fill level indicators, electronic

- Fill level gauges for liquids

- Level measurements

- fuel level sensors, capacitive

- Fill level monitoring

- Direct current converters (DC/DC converters)

- Fill level sensors for automobiles