BIZERBA SE & CO. KG - The Open World of Finest Weighing Solutions. Since 1866.

Germany

Manufacturer/ Producer

BIZERBA SE & CO. KG

Germany

Quick and reliable detection of all ferrous and non-ferrous metals in packaged and unpackaged piece goods. The compact metal detection system offers you safe performance and highest detection sensitivity. With its robust stainless steel conveyor belt construction the VARICON+ inspects piece goods of up to 50 kg. A very short metal-free zone (MZ) ensures interference-resistant, reliable inline metal detection. To suit the area of installation the system is available with a modular belt (wet area) or a flat belt (dry area). The conveyor belts are available with variable belt widths. The motor controller is fitted either with a conveyor stop in case of metal detection or an application-specific rejection system. For easy and thorough cleaning the VARICON+ series has a hygienic design. Quality which is reflected in BRC, IFS and HACCP certifications. The VARICON+ comes with IP65 protection. Higher IP ratings are optionally available.

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

The CWL Max is a top performer of the dynamic scales in the logistics area. Available as a dual or triple scale, the weighing system particularly shows its strength by reducing distances between packages when working with different package sizes. The dual scale CWL Max is making use of the technical advantages of two or three integrated weighing systems by selecting the ideal weighing system based on package length. Therefore it efficiently establishes the weight value even if the next product is already waiting. As a result the output of this dynamic scale, as compared to a single scale system, can be significantly increased without affecting the overall length and belt speed of the system. Consequently, you benefit from a higher package throughput. The CWL Max meets the requirements for verification as an automatic catchweigher (ACW) and as an automatic checkweigher (AChW).

Request for a quote

BIZERBA SE & CO. KG

Germany

Specially designed for small and medium throughputs of up to 500 packages per hour, DWS static determines barcode, volume and weight in a single work step providing all relevant data for calculating freight and creating freight papers at the press of a button. With DWS static all shipping cost relevant data can be recorded at the touch of a button. The system comprises the tried and tested volume measuring system VMS 510/520, a robust static scale and a barcode scanner to read code information. All components are integrated in a sturdy mechanism. The system is ready for operation after a few minutes and is approved according to applicable standards. Also for full data recording in ERP systems verified systems are required.

Request for a quote

BIZERBA SE & CO. KG

Germany

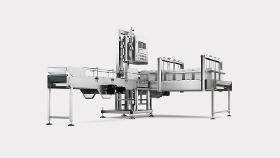

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously. Your advantage: Possible operating errors resulting from incorrect settings can be minimized. The FSL-EVO S is also available as an Ex model for zones 1 and 2. Same as with all our Ex models it meets ATEX guidelines.

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time. The various manual closing systems prevent the containers from leaking. FSL-ECO S ensures smooth processes. Our options allow you to expand your system individually and adjust it to your requirements. Interchangeable filling valves, for example, ensure a hygienically perfect...

Request for a quote

BIZERBA SE & CO. KG

Germany

This semi-automatic, flexible all-round filling system FSL-PRO S ensures your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. This compact unit is ideally suitable for minimal space. The professional, safe filling of various liquids is an important processing step for many companies. Also particularly difficult to process products are reliably filled and weighed in different containers. Besides this flexibility you benefit from reduced downtimes. You can change products and units quickly and easily. The FSL-PRO S is also available as an Ex model for zones 1 and 2. Same as with all our Ex models it meets ATEX guidelines. No need to remove the filling valve for efficient and thorough cleaning of the system. You save work steps and time. Ideal for frequent product changes. The filling system can be easily run by an operator and allows parallel working: Optional expansions let you perform capping and...

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container. Less over and under fillings. When used with a dual scale, the filling process is considerably accelerated while working with the same precision and quality: In parallel, you can fill and weigh on one scale and close and further transport...

Request for a quoteManufacturer/ Producer

Wilhelm-Kraut-Str. 65

72336 Balingen - Germany