- europages

- >

- Box construction

- >

- BRITISH CONVERTING SOLUTIONS LTD

BRITISH CONVERTING SOLUTIONS LTD

United Kingdom

Manufacturer/ Producer

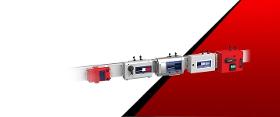

BCS provides box making machines for both cardboard and corrugated boxes or cartons. Our Customers include box or carton plants and end users who use BCS machines to make their own boxes in house. BCS machines incorporate the very latest in technology making them not only very quick to set up to make different sizes and styles of boxes or cartons but they are also the most energy efficient machines available. The BCS AutoBOX is the most advanced boxmaking machine available today. It is designed to allow companies to produce short and medium runs of corrugated boxes quickly and easily. BCS gluers provide box folding and gluing machines for both cardboard and corrugated boxes and cartons. Machines are suitable for straight line or Multi-Point gluing.

Website

Manufacturer/ Producer

BCS House, Blackburn Road

Townsend industrial estate

LU55BQ Houghton Regis - United Kingdom

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- pages.epage-home.site-status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of BRITISH CONVERTING SOLUTIONS LTD

- Box construction

- box making machines

- corrugated box making

- multipoint gluing machines

- corrugated paperboard cases

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ZAMKO

Netherlands

Our custom made cardboard pallet box is often used for export and product shipments to customers. They are also used for internal processes within production companies. CUSTOM MADE Carton pallet boxes are available in many sizes, up to a length of 2400mm. Depending on the products inside and the desired load capacity, we choose the appropriate type of box and box construction together with you. LOAD CAPACITY Cardboard pallet boxes can have a load capacity of more than 1,000kg and with a special construction even up to 4,000kg. These pallet boxes can not only handle heavy loads but also offer solid benefits to manufacturers and distributors who need to transport and store products on a daily basis, regardless of their size, shape, or weight. The material they are made of – corrugated cardboard – makes cardboard boxes easy to recycle, reusable, and cost-effective for one-time use.

Request for a quote

GSW SCHWABE AG

Germany

Safe upending (90°) and rotating (180°) of coils Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type highstrength chain Rotating drive via welded surfacehardened sprocket, integrated in base Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

GSW SCHWABE AG

Germany

Safe upending of coils (90°) Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type Highstrength chain Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

EAE ELECTRIC

Turkey

Tap-Off Boxes are used to draw power from the Busbar TrunkingTo supply the Rack Cabinets with the required energy and monitor the consumption. EAE offers a wide range of Tap-Off Boxes constructed out of sheet metal and plastic.Customized Tap-Off Boxes provide an independent setup for choosing a variety of electrical equipment to be installed regardless of the brand. Energy Metering over RJ-45 connection, utilizing the structured cabling is one of the value-added features of the EAE Tap-Off Boxes. As for the real-time monitoring of energy consumption and other critical power parameters in the data centres, thereby creating a more efficient IT infrastructure.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free