- europages

- >

- Conveyor belts

- >

- ERO JOINT .TANALS

- >

- Conveyor belt

Conveyor belt

Description

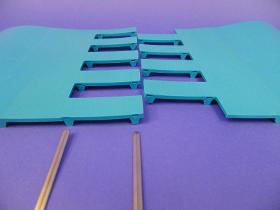

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

- Conveyor belts

- Conveyor systems

- transmission belts

Similar products from ERO JOINT .TANALS

ERO JOINT .TANALS

France

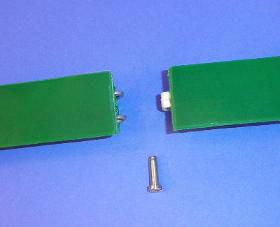

The mechanical fastening system ERO Joint® is available in conveyor belts with a thickness over 1mm. The assembly is made by threading of 3 transversal pins (stainless steel or polyacetal pins can be used). ERO Joint® splice is integrated into the conveyor belt, with no structural, width and colour changes. Tensile Kevlar cord can be embedded in Polyurethane upon request. Anyway using ERO Joint® conveyor belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® conveyor belts are easy to assemble.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical joint system, you will save time and optimize your production downtime by reducing the repair time. The mechanical assembly of ERO Joint® round belts is substantially better compared to another mechanical joint system. There is no other mechanical joint system in round belts with traction cord. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® round belts are spliced in our production using a patented process and fitted with the length requested. Anyway using ERO Joint® round belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® round belts are easy to assemble. Alternatives Hollow round belt with fastening system Hollow round belt with connector are only used for very low mechanical resistance.

Request for a quote

ERO JOINT .TANALS

France

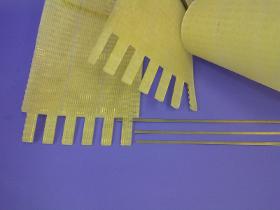

Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The recommended minimum diameter for pulleys is 50mm. The mechanical joint system ERO Joint® WT is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® WT are lasting solutions. The ERO Joint® WT splice shape may be adapted in order to increase the mechanical resistance. ERO Joint® WT is the only one solution of mechanical belt fasteners in wide timing belts. The ERO Joint® WT wide timing belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

In all cases, the mechanical fastening systems ERO Joint® are linked to a traction cord embedded in the belt in order to provide the required mechanical resistance. (ERO Joint® is also available in belts without traction cord). In such cases, a traction element is added to assure the mechanical resistance of the mechanical hinge joint. Anyway using ERO Joint® V-belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® trapezoidal belts are easy to assemble.

Request for a quote