- europages

- >

- Rubber and plastic welding

- >

- DOREY

- >

- products

DOREY - Welding and Cutting Solutions for Flexible and Semi-Rigid Materials

France

Distributor

DOREY

France

The new Miller Weldmaster T300 Extreme combines heat, speed, pressure and precision with precise positioning of the weld head for increased efficiency and speed with an ergonomic design. With 4 positions and 3 arms integrated into one machine, you have the versatility to make almost any product. Larger, rotating/tilting, easy to use screen Available in hot air, hot iron, or both for greater product versatility Precision sealing head with three synchronized controls for increased efficiency and higher speeds. Test mode allows the operator to quickly find the optimal heat and speed setting for the machine. Adhesive tape dispenser included to easily apply Velcro weld and extruded profiles to any product. Built-in material extractor to reduce labor or long weld seams.

Request for a quote

DOREY

France

The usable cutting area is available in multiple sizes allowing to process small to extra-large fabrics rolls. The SM-332-TA reaches speeds of up to 90 m/min with an acceleration of 1G with a motion repeatability +/- 0,1 mm. The cutting area is sectioned to concentrate the vacuum power in specific areas. Pressure bar and side grippers for synchronized movement of the conveyor with the fabric. Motorized conveyor belt to maximize cutting accuracy on long lengths. The SM-332-TA can be equipped with an optional motorized unwind system for large rolls with automatic material alignment control and correction and a digital tension control system.

Request for a quote

DOREY

France

TYPES OF OPERATIONS TO RUN (SEE VIDEOS ENCLOSED) Double Tube Sewing System Cured in Place Pipeline System Cured in place welding machine Cured In Place Pipeline Manufacturing SINGLE or DOUBLE Layer Welding and Sewing Operations DESCRIPTION This fully automated welding or sewing system manufactures cured in place pipelines or rehabilitation tubes. The machine is capable of welding or sewing two layers of fabric simultaneously one layer of non woven felt on the inside and one layer of coated felt on the outside. The coated felt layer can be coated with PVC, polyurethane, polyethylene or polypropylene. This machine can weld or sew both layers, tack welds layers together all automatically inline simultaneously, saving time improving consistency and increasing quality. FEATURES, FUNCTIONS, & BENEFITS Multiple unwinds for off roll production Continuous operation for increased production Capable of welding or sewing both layers to meet your finishing needs

Request for a quote

DOREY

France

Miller Weldmaster T 300 Extreme combines versatility and precisely controlled operating parameters within an ergonomic design and interface for easy operation, speed, accuracy, and productivity. FEATURES, FUNCTIONS, & BENEFITS Weld rollers are independently controlled which helps produce an expanded range of products and materials. Easy operation with our touch screen and 25 memory settings. Guides and accessories to weld hems, overlaps, hem with rope... Equipped with dual arms The “Table Arm” takes care of straight seams for applications like tarps, awning and tents; while the curve arm manages curves and unique shapes for applications like boats and inflatables. Built with one person operation in mind. It comes with a speed of up to 20 meters per minute*. Welds PVC, PE, PU and many more. Can weld acrylic with our special Extreme Seam TapeTM. Comes furnished with the new “Seam Screen.” It allows users to digitally control all welding parameters in up to eight different languages.

Request for a quote

DOREY

France

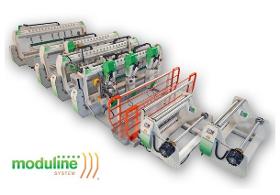

Miller Weldmaster is excited to present our new line of multisealing automated solutions, the Moduline system. Our new Moduline system is designed for the customer looking to increase business profits by automating their production process. Miller Weldmaster designs machines specifically to meet your automation needs while keeping your production and payback concerns in mind. Our years of industry knowledge enables us perfectly pair your application with the properly tailored Miller Weldmaster Automated machine. The Moduline System with its unique design enables you to select multiple automation options regardless of your production demands. FEATURES, FUNCTIONS, & BENEFITS Modular welding gantries for product versatility Modular unwinds with load cells for fabric tension Modular catwalk for simple seam inspections Modular upper and lower welding heads for versatility and accessibility Modular cutting heads for near final productivity

Request for a quote

DOREY

France

Miller Weldmaster T 600 Extreme combines versatility and precisely controlled operating parameters within an ergonomic design and interface for easy operation, speed, accuracy, and productivity. FEATURES, FUNCTIONS, & BENEFITS Easy operation with our touch screen and 25 memory settings. Weld rollers are independent, controlled witch helps produce an expanded range of products and materials. Guides and accessories to weld hems, overlaps, hem with rope... Equipped with dual arms The “Table Arm” takes care of straight seams for applications like tarps, awning and tents; while the curve arm manages curves and unique shapes for applications like boats and inflatables. Inboard puller to help to feed heavy and wide material. Built with one person operation in mind. It comes with a speed of up to 15 meters per minute. Welds PVC, PE, PU and many more. Can weld acrylic with our special Extreme Seam TapeTM. Comes furnished with the new “Seam Screen.” It allows users to digitally control

Request for a quote

DOREY

France

From the innovators of welding automation, Miller Weldmaster presents the DH7600. Designed to finish the outside edges of almost any size product, the DH7600 is an economical solution to finish 2 sides at one time. Available with almost any seam type, the DH7600 is available with an optional conveyor table for additional fabric handling. Double your finishing production The model DH7600 FEATURES, FUNCTIONS, & BENEFITS Throat capacity available in 4.5M or 7.6M (14.76t or 24.93ft) Dual hot air and hot wedge heat systems for seaming any any type of industrial fabric Independent cool down cycle Operator foot pedal to initiate welding process Miller Weldmaster PLC smart screen

Request for a quote

DOREY

France

The TG Series of Geo and Cover fabricating machines are designed to eliminate excessive fabric handling. The TG series will efficiently produce almost any size Geo Liner or Cover. By using our exclusively designed welding and pulling system, the TG3600 will dramatically reduce labor and increase production. Because we use your floor as our welding surface, the TG3600 only takes up limited floor space. No pre pulling, no folding, no excessive handling.The model TG3600. FEATURES, FUNCTIONS, & BENEFITS Throat capacity available in 3.65M (12ft) Cradled unwind stand Material fabric clamp Adjustable operator control platform Track assembly for up to 76.2M (250ft) of travel included Hot air heat system Multi color fabric requires 2 unwinds

Request for a quote

DOREY

France

From the innovators of welding automation, Miller Weldmaster presents the i6500W Series of Indexing welders. This recipe driven curtain producer will enable your operator to easily finish your vertical webbing and vertical seams effortlessly. After the fabric is placed on the automatically driven table, the welding head will advance to the start position and finish all of the vertical webbings hands free. All webbing are pre fed, pre cut, and precisely positioned with no measuring. Speed, versatility, precision and labor reduction... the model i6500W. Also available To weld horizontal webbings on truck curtains To weld anti vandalism webbings SPÉCIFICATIONS, FONCTIONS ET BÉNÉFICES Throat capacity available in 6.5m to 14m Independent Quad heat system Automatic rotary webbing cutter Miller Weldmaster PLC Smart Screen Custom indexing clamp system High speed hot air welding technology Power friendly worldwide

Request for a quote

DOREY

France

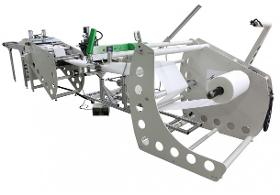

The new Miller Weldmaster filter tube line uses our experience from our previous filter systems and introduces revisions that will make filter tube production even easier. This system makes loading your material easier by giving a laser guideline to help ensure the roll is positioned properly which makes set up easier. From the unwind your material will be guided into the heat seamer with the help of a pre fold system and an adjustable tubing guide which will help you make perfect diameter tubes. The tube will then be brought into the conveyor cutter system which will cut the tubes to the exact length you need and our newly designed sweep system will allow you to push your finished tubes off the side into a take away bin. FEATURES, FUNCTIONS, & BENEFITS No operator involvement reducing labor. It is capable of welding up to 90 feet per minute depending on the fabric which will help increase production.

Request for a quoteDistributor

250 rue des Artisans

26750 Chatillon St-Jean - France

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

EC PLAZA

South Korea

Daehun Inc. has been supplying a wide range of rubber molded parts and sheets from China worldwide mainly in North America and Europe since 1990. - Daehun is manufacturing rubber molded parts for automotive & industrial and make constant efforts to sustain high-quality level for customer satisfaction firstly. - Daehun has the newest rubber test equipment and professional manpower in this field. Our development/quality control team meet the quality customer requires and provide benefit to customers by cost-reduction at the same time. - Daehun management utilizes our IATF Quality Systems as a focal point of our organization's approach to customer satisfaction. We subscribe to our quality program and continual improvement in every factory of our organization. - We pride ourselves in our ability to manufacture products to exacting quality standards and are dedicated to on-time performance.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Temperature range: 250 °C to 3200 °C 4-year warranty Durable IP65 (NEMA4) housing Manual Variable focus Sighting options: Laser through the lens and Visible through the lens Video Camera through the lens and Visible through the lens LED through the lens and Visible through the lens LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring and field calibration Single or two color models available APPLICATIONS Metals processing: molten metal/forging, hot rolling mills, rod/wire mills Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Broad temperature range 50 to 3200°C 4-year warranty Durable IP65 (NEMA4) housing Visible through the lens sighting and manual variable focus plus optional laser sighting, video camera, or LED sighting LAN/Ethernet interface with PoE for sensor communication (ASCII, Video, and Webserver) Profinet interface option Programmable relay output Fail-safe alarm Isolated analog input/output Rugged stainless-steel housing Dirty-window alarm Endurance software for remote configuration, remote monitoring, and field calibration In addition to single-color models, the series also comprises two-color (ratio) pyrometers and models with a remote sensor head (Endurance Glass-Fiber). APPLICATIONS Metals: forging, hot rolling, rod/wire production Heat treating & annealing Induction heating Lightbulb and halogen lamp production Glass melting Semiconductor furnaces Cement & lime kilns Refuse burning Carbon graphite production Foundry & welding Rubber & thick plastic

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free