- europages

- >

- Polishing - steels and metals

- >

- ECOROLL AG WERKZEUGTECHNIK

ECOROLL AG WERKZEUGTECHNIK - surface matters

Germany

Manufacturer/ Producer

Product catalogue preview

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL single-roller tools are usually used for roller burnishing. They machine a wide range of complex contours and surfaces such as concave fillets and grooves as well as cylindrical and conical outer surfaces and bores. These tools comprise series EG, EF and FAK. EG tools are divided into tool families EG5, EG14, EG45 and EG90. They burnish cylindrical outer surfaces and bores, conical bores, plane surfaces and fillets. For deep rolling of fillets and thread root radii EF, FAK and FA tools are used. Single-roller tools consist of a tool body equipped with a tool shank, a spring assembly that allows the roller head to move with no play and very low friction. The standard version contains a dial indicator for indirect indication of the spring force. As an option, the tools can be equipped with ECOsense process monitoring for external display of the spring force. The roller head is attached to the flexible, spring-loaded section of the tool body.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL multi-roller tools are usually used for roller burnishing. Types G, R and RA machine cylindrical through and blind bores, stepped bores and cylindrical external surfaces including similar non-cylindrical surfaces. . RP, RK, RKA and RKAK tools are designed for plane surfaces, cones and spherical surfaces. RH/RHA tools deep roll fillets and chamfers. FA tools deep roll large thread root radii. All ECOROLL multi-roller tools can be used on CNC turning, drilling or milling machines and machining centers or on conventional machine tools. They can be characterised by reliable functioning and high precision. Adjustment of diameters is very convenient, and only nominal lubrication is required. Futhermore, replacement of wear parts is very simple. This uncomplicated maintenance and short primary processing times enable significant time savings.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

The tools HGx-1, -2, -4, -11 machine bores, complex inner contours and fillets. Depending on the pressure supply, tools types HGx-5, -7 (integrated) and HGx-9, -10, -19 (external) machine rotationally symmetrical contours. HGx-20 and -29 are intended for narrow cylinders and thin-walled components. As accessories, ECOROLL offers hydraulic units, rotary units for the connection of turret machines. Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

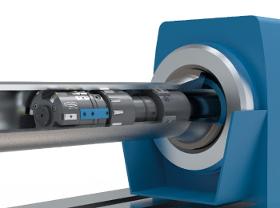

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quoteECOROLL AG Werkzeugtechnik is a leading provider of tools for fine mechanical surface machining. ECOROLL AG Werkzeuge – which employs around 80 people – develops, manufactures and distributes tools for burnishing, roller burnishing, skiving burnishing and machine hammer preening. ECOROLL tools are used wherever there are special demands for surface roughness or component strength. The burnishing or roller burnishing process is carried out on commonly used machine tools directly after pre-machining and achieves surfaces with very low roughness (< Ra 0.01 / < Rz 1.0 µm), comparable to results when sanding, honing or polishing. This is thanks to the forming of the component edge zone roughness profile without material removal, while also increasing the dynamic strength and edge zone hardness. ECOROLL can also supply a comprehensive range of standard tools from stock. Another of our strengths is developing and manufacturing special solutions according to customer requirements. With our team skilled in distribution, design and applications technology, we create tailor-made tools and processes for special customer applications. Our applications team also offers the opportunity to test our technologies through machining trials at ECOROLL's or the customer's premises and to find any ways of improving the surface finish.

Website

Documents

Mechanical Burnishing Tools

Manufacturer/ Producer

Hans-Heinrich-Warnke-Strasse 8

29227 Celle - Germany

Company info

Key figures

-

- Company headcount

- 51 – 100

Organisation

-

- Year established

- 1995

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Terms of delivery (incoterms)

- Purchaser

- Shared

- Vendor

Activities of ECOROLL AG WERKZEUGTECHNIK

- Polishing - steels and metals

- Component strength

- Compressive residual stresses

- Dynamic strength

- Increasing strength

- Roller burnishing

- Roller-burnishing tools

- Threaded fasteners

- smoothing

- Burnishing