FESSMANN GMBH UND CO KG

Germany

Manufacturer/ Producer

FESSMANN GMBH UND CO KG

Germany

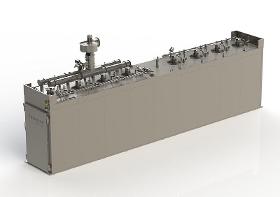

The T1900 is the ideal choice for small and mediumsized companies In spite of the minimal space demand thanks to a compact design, the system can live up to the "big" FESSMANN models in terms of technology and performance! If the space conditions are extra tight, we have another ace in the hole The T1800! It provides all applications of the T1900 with a ceiling height beneath 2 m. And the volume is just amazing!

Request for a quote

FESSMANN GMBH UND CO KG

Germany

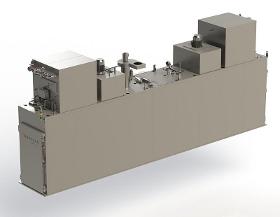

Very small weight loss, short process times, low maintenance and operating costs The T3000 by FESSMANN is one of the most successful universal systems in the world. It permits the production of high piece numbers in best and uniform quality as costefficiently as possible – while confidently mastering the challenges of modern butchers' operations!Completely made of stainless steel with a low construction height Automatic cleaning aid serially installed Various heating types for selection Optionally with a climate package for optimal maturation Smooth circulation blower for consistent smoking climate in the entire system and best smoking results Serial equipment with our FOOD.CON control for reproducible results Modular build for flexible expansion up to 6 trolleys Can be combined with any smoke generator from the RATIOfamily

Request for a quote

FESSMANN GMBH UND CO KG

Germany

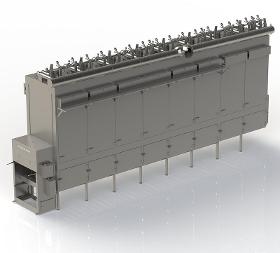

The industrial system Ti3000 will get more than 1.5% more yield as compared to other systems at the tried and tested FESSMANN quality! Completely made of stainless steel and built steamtight out of panels, the Ti3000 is universally usable according to your specific needs. The central unit technology also convinces with its flexibility and best circulation air outputs at short process times.Panel construction and central unit technology for best air and process outputs Higher flexibility in implementation of customerspecific product requirements by smooth fan speeds Higher system capacities by faster process times = higher yield Use of all known supply trolleys for industrial use possible Use of "overlength" supply trolleys and transport frames Automatic door opener serially included Automatic CIP cleaning system serially included

Request for a quote

FESSMANN GMBH UND CO KG

Germany

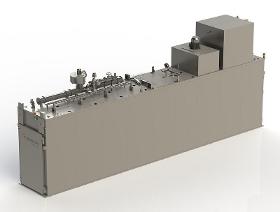

The industrial smokehouse Ti7000 delivers impressive quality in impressive time! The special air guidance flap of the system ensures that the same conditions prevail everywhere in the system at any time during the process, even with doublerow loading. Double row construction for highest capacities Use of trolleys up to a width of 116 cm (46") Special air guidance flap for highest product uniformity Automatic CIP cleaning system with particularly effective rotary nozzles FOOD.CON 2 control as standard for best process control

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TF3000 combines the Turbomat T3000 and the intensive cooling system IK3000 in a single closed system. This means one thing most of all Best output per chamber part for the shortest process times. The automated transport system not only reduces operating costs, but also increases production capacities in the system. Maximum output per chamber part Production justintime, controllable and reproducible processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The semicontinuous TFi3000 for industrial use is not a compromise, but rather the combination of the benefits of two entirely different systems! It permits smoke, heat and cold treatments in a single production step. Automated work processes lower your operating costs while at the same time increasing production capacities. Efficient combination of Ti3000 & IKi3000 Production justintime, controllable and reproducible work processes Much lower germ formation and contamination – for longer durability Automatic transport system Producing, packaging and delivery in a very short time Lesser demand of cold storage capacities Higher trolley capacity as comparable floor conveyor systems by low construction

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The multifunctional TF4000 by FESSMANN combines highest production capacities with best quality. In the continuous system, the products go through several heat treatment and cooling units, and leave the machine ready for packaging. The innovative serpentine conveyor technology achieves the shortest process times at the lowest weight loss – and decisively reduces the amortisation time of the system!Considerable saving of energy costs Use of any smoke system possible Only 25% of the space demand of batch systems for best return on very small space Fully automatic control and monitoring of the production processes Temperature and humidity can be controlled separately in every treatment zone Unparalleled hygiene, separation of goods input and output (HACCP) Outstanding quality results in colour and flavour at minimal weight loss as compared to batch systems

Request for a quote

FESSMANN GMBH UND CO KG

Germany

By using the new TRANS.LUB chain oil from Fessmann you have "peace of mind" in the knowledge that the chain for your continuous line TF4000 is being lubricated perfectly. Not only is this synthetic highperformance oil precisely matched to the special working requirement of the TF4000 chain, but additionally can be used throughout the food industry due to its excellent lubrication properties.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The Autovent 3000 ensures optimal cooking processes at smallest weight loss without any fans at all! Instead, the system's patented nozzles use the internal dynamics of lowpressure steam, converting it into air speed and heating energy. For you, this means Shorter cooking times and weight loss reduced by up to 15%! High turbulences due to patented AUTOVENT nozzles and air velocities of up to 200 m/s Short cooking times and up to 15% less weight loss Temperature difference across the system no more than 1 °C Uniform products at highest quality Very low maintenance and operation costs from dispensing with fans Long service lives from stainless steel construction and steamtight welding allround

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The TFi3000 Autovent is a true efficiencywonder! The patented procedure for lowpressure steam cooking without any fans at all, in combination with automated work processes, reduces the operating costs to a minimum. Cooling of the products in the closed system, directly subsequent to heat treatment, also ensures ideal hygiene conditions and increases durability. Production justintime, controllable process with reproducible work processes Automatic transport system Much lower germ formation and contamination – for longer durability Short cooking times and weight loss reduced by up to 15% Temperature difference across the system no more than 1 °C Uniform products at maximum quality due to turbulences and air velocities up to 200 m/s Very low maintenance and operation costs thanks to dispensing with fans Long service lives due to stainless steel construction and steamtight welding allround

Request for a quoteManufacturer/ Producer

Herzog-Philipp-Strasse 39

71364 Winnenden - Germany