HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

Manufacturer/ Producer

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The inspekt duo is a versatile two-spindle testing machine for test loads of 5 to 10 kN. It is a further development of the inspekt table blue series from Hegewald & Peschke. The inspekt duo machine series is ergonomically designed. Characteristic features include the large base plate, which allows the connection of peripheral devices such as extensometers, as well as the coupling of a tool tray and the equipment with protective doors. This guarantees use in harsh production environments as well as in sterile laboratories. The LabMaster materials testing software is available for fast and reliable evaluation of test results. As a cost-optimized table-top device of low weight, it is suitable for both simple and customer-specific tensile, compression and bending tests on a wide variety of materials, including wires, plastics, elastomers, paper, cardboard, food, hygiene articles, textiles, springs and wood.

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The universal testing machine inspekt solo is a very lightweight testing machine, which has been designed for simple standard tests or customer-specific, more challenging tests. It stands out due to its convincing cost/performance ratio and the user-friendly manner of operation. In connection with the testing software LabMaster, inspekt solo universal testing machines can determine material characteristics of wires, foam plastics, elastomers, plastics, paper, cardboard, textiles, foodstuffs, and components in a quick and easy way. The Inspekt solo for test loads up to 2.5kN is a further development of the successful inspekt mini series for standard-compliant material and component testing in the low load range. In order to be able to better represent the wide range of requirements for this machine series, new technological possibilities have been exploited. Instead of DC motors, a new drive concept with stepper motors was developed - brushless, low-wear and noise-optimised.

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The testing machine series inspekt table was developed for standard-compliant materials and component testing in the medium load range, with particular attention paid to reliability and flexibility. It is ideally suited for materials testing of plastics or non-ferrous metals as well as for testing smaller components, for example from instrument engineering. In combination with our user-friendly testing software LabMaster, standard-based and customer-specific tests can be easily implemented. Testing machine, testing software and our extensive range of accessories such as specimen grips and testing tools, extensometers or temperature control devices are optimally matched to each other and offer the ideal testing system for a wide variety of testing applications (tensile tests, compression tests, bending tests, peel tests,...). Inspekt table is available in six different load levels from 5 kN to 250 kN.

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The universal testing machine inspekt offers high-class mechanic precision, frame stiffness and modern control electronics. Customers also profit from the convincing cost/performance ratio. The top-quality, rugged machines can be used for almost any testing task. The size of the test room of the individual machines can be customized. It is also possible to add one or more test room. In combination with our user-friendly testing software LabMaster, standard-based and customer-specific tests can be easily implemented. Testing machine, testing software and our extensive range of accessories such as specimen grips and testing tools, extensometers or temperature control devices are optimally matched to each other and offer the ideal testing system for a wide variety of testing applications (tensile tests, compression tests, bending tests, peel tests,...). - Solid construction for highest measuring and control precision - Flexible design for versatile applications

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The inspekt blue material testing machines were designed for standard and routine tests. These universal testing machines are used, among other things, in quality assurance and are characterised by a particularly attractive price/performance ratio. The inspekt blue is suitable for tensile tests, compression tests, peel tests and bending tests on various materials. In combination with the ergonomic design and the new brushless drive concept, a safe and fast measurement is guaranteed with simplest operation both in the rough production environment and in the sterile laboratory area. Main features: - innovative brushless drive without gear drive - reduced noise pollution due to low engine speed and optimized frequency range - freely selectable control of crosshead travel, force or elongation - high-precision force measurement by strain gauge force transducer - versatile adaptation of accessories and additional force transducers

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

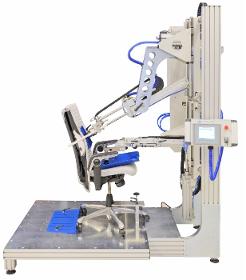

Various test rigs: - Alternating bending test rig for seating furniture: seat/back rest load acc. to BIFMA X5.1, EN 581-2, EN 1335, EN 1728, BS 5459 - Double test rig for chair testing: seat and backrest tests, side-to-side tests and armrest tests according to EN 1335, EN 581-2, EN 1728, BIFMA X5.1, BIFMA X5.4, BIFMA X6.5, BS 5459 - Test rig for alternating bending tests of arm rests according to EN 1335, EN 1728, EN 581-2, DIN 4551, BIFMA X5.1 and BSI/BS 5459 - Portal drop test rig: testing of chairs, stools, tables, beds acc. to BIFMA X5.1, BIFMA X6.1, EN 581-2, EN747-2, EN 1728, EN 1730, ISO 7173, EN 12520, EN 14072 - Test bench for determining the stability of chairs in accordance with the standards EN 1022, EN 1729-2, EN 581-2, ISO 7174-2 and BIFMA X5.1 - Test rig for tilting drop tests at chairs according to DIN 68878/1 - Swivel test rig according to DIN 4551, EN1335, NEN 1812 and BIFMA X5.1

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

The 1D measurement device “light” serves for the length measurement of long, narrow workpieces in the productions environment. This product offers a cost-effective alternative exactly for such measurement tasks where a sliding calliper is too short and a measuring tape is too inaccurate. With the 1D measurement device “light”, linear dimensions can be gathered quickly and reliably in the simplest manner. Essential characteristics • Light-weight, cost-effective construction using high-quality components with deliberate • Universal modular system – the equipment can be individually arranged - measuring length from 950 mm to 3,850 mm in a variety of graduations - accuracy: ± (0,06mm + 0,02mm x L), L=measuring length in m - very easy to use - use-oriented configurable (workpiece supports, measuring equipment) - high-quality, robust Magnescale® measurement systems - optional PC-/Printer Interface RS232/USB - optional workbench (also mobile) and workplace equipment

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

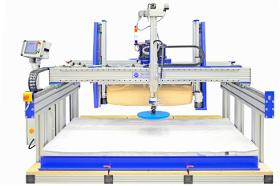

Entire testing according to EN 1957 in one test stand possible No falsification of measured values because no rearrangements or transport of the mattresses and cushion frames between the durability test and the measurement of the hardness values H and HS are necessary The system can also be used for tests according to ASTM F1566 (necessary accessories: corresponding pressure plate for hardness testing, roller for tests according to ASTM F1566) The adjustable testing table frame guarantees a high flexibility for specimens of different sizes Flexible test parameter entry (e.g. number of cycles, test load) Automatic shutdown of the machine when the pre-set number of cycles is reached Exensive testing and evaluation software Alternative: Single test stand for durability tests on mattresses, spring cores and (box spring) beds according to EN 1957/ASTM F1566 Single test stand for the hardness measurement on mattresses, spring cores and (box spring) beds according to EN 1957/ASTM F1566

Request for a quote

HEGEWALD & PESCHKE, MESS- UND PRÜFTECHNIK GMBH

Germany

Testing machines for torsion testing are mainly used in science, research and teaching, in testing laboratories and in production control during production.They are used to determine the torque load of specimens made of different materials in static tests, e.g: Plastics, composite materials Screws, cardan shafts Twisting tests on wires according to DIN ISO 7800 and ASTM A938 as well as alternating twisting tests on wires according to DIN ISO 9649 Calibration of torque sensors

Request for a quoteManufacturer/ Producer

Am Gründchen 1

01683 Nossen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

QUELLTECH GMBH

Germany

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Plane Mirrors (general, λ/1 and λ/4), for use within 3D Mapping Applications in a range of materials such as Soda-lime float glass, white float glass, and BK7 glass. Plane mirrors also known as front surface mirrors or first surface mirrors are used within 3D Mapping Applications. As stock we hold a number of general purpose, λ/1 and λ/4 with a range of up to 6 types of coatings such as Enhanced Aluminium, Ali/SiO2 and Ali/Mgf2. Our general purpose grade mirrors are made from good quality float glass and generally available in thicknesses of 1mm, 3mm and 6mm as standard. How our mirrors are used within 3D Mapping, is they are used as a sender and receiver of a laser beam that will take a reading of a specific surface, and from that reading it can create a 3D map of the surface that is has read. FOR MORE INFORMATION READ THE PDF..

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free