IKOI SPA

Italy

Manufacturer/ Producer

IKOI SPA

Italy

Manufacturing plants, machines, technologies and engineering services on PMs metallurgy, casting, pyrometallurgy and physics separation of pure and alloyed Precious Metals.

Request for a quote

IKOI SPA

Italy

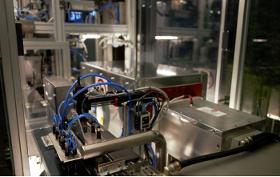

FCC ® represents an unprecedented technological leap offering our customers higher productivity, higher safety and high sustainability. This is the evolution of our long-time know-how in casting technology: thanks to the experience of more than one-hundred Flameless Tunnel® furnaces installations, IKOI S.p.A. developed a revolutionary system specifically designed for Good Delivery and SGE bars, that comply with Industry 4.0 standard and that can significantly reduce CO2 emissions, following the ESG principles. FEATURES AND BENEFITS: FULLY AUTOMATED SUITABLE FOR CRYSTALS OR GRAINS SAFE AND EASY TO OPERATE HIGH PRODUCTIVITY NO OPEN FLAMES REDUCED FOOTPRINT CONISTENT QUALITY COMPLIANCE WITH INDUSTRY 4.0

Request for a quote

IKOI SPA

Italy

ALS® – Acidless Separation® by IKOI is a revolution in the metal refining industry. It achieves silver and gold separation without any chemicals. This Green Technology has obvious benefits for the environment and the communities, as well as a positive effect on the economics of the industry. ADVANTAGES OF ALS®: No use of chemicals. ALS® is a real Green technology No Precious Metals losses Fast process Safety and security No need of Precious Metals lock-up Easy metal control and accountability at every step of the process Easy to use Flexible (it can process a wide range of alloys) Low OPEX Low Maintenance No need of additional equipment (scrubbers, filters, waste water treatment plants etc.)

Request for a quote

IKOI SPA

Italy

Continuous electric induction system furnace straight type for the production of gold or silver bullion in controlled atmosphere, suitable for the working with graphite ingot moulds. ADVANTAGES OF FLAMESS TUNNEL Significant reduction of rejects due to increased quality of the bars Better for the environment (Green technology) Cancellation of precious metal losses (loss of weight: 0,01 g/kg) Safer for the operators Significant reduction of electricity consumption Considerable reduction in radiant and convective heat loss Significant reduction of the labour time for the production Not specialized skilled workers requested Fast production times Increasing of the material turnover Excellent surface finishing thanks to fss system - flat & shine surface system

Request for a quote

IKOI SPA

Italy

IKOI’s Prime Refining Unit is the result of ten years of experience in metal vacuum distillation. The technology is based on the physical principle of evaporation. It is a revolutionary green technology that can pre-refine precious metals without using acids or chemicals. This plant is specifically designed for small and medium refiners who need flexible, fast and sustainable way to process a variety of feedstocks, including dore bars, jewellery scraps and industrial waste with precious metal content. Prime Refining Unit removes silver and volatile elements from Au/Ag/Cu alloys using vacuum distillation technology. The exceptional capabilities are essential to reduce silver content on Au/Ag/Cu alloys without any chemicals and without any by-products. In this way, the alloy can be easily dissolved in a traditional Aqua Regia process or refined using gold electrolysis.

Request for a quote

IKOI SPA

Italy

The COMPACT automated gold bars production plant includes the latest technological developments and the experience of over 100 installations in a small automatic unit. The automated vacuum-transferring system loads the grains inside the hopper and the COMPACT plant provide the finished ingots directly to the output area. DETAILS: Fully automatic Ultra-compact, ultra-precise and ultra-fast weighing machine; Angular Cooling zone to reduce the total footprint; Inductor electromagnetic shielding according to CE regulation; Industry 4.0 Ready

Request for a quote

IKOI SPA

Italy

The machine accurately doses gold and silver grains for the prodcution of bullions and cast bars. The Preci-dos is completely automatic, with dosing cells and grains transfers completely controlled by PLC. It has a number of steps to achieve accurate control on final weight. The grains container in the machine are loaded by gravity into the pre-dosing scale, to approach the final desired weight. After the pre-dosing step, a second phase starts to reach the final desired weight by adding a controlled quantity of gold or silver wire or powder (depending on customer specification) and the discharge the correct quantity of material into a container. To maintain accuracy and productivity, the machine is capable of self-learning, based on the continuous use. In particular the machine can statistically anticipate the average drop time of a single grain, to avoid overshoot.

Request for a quote

IKOI SPA

Italy

Induction static melting furnace for manual graining production of precious-metal alloys in graphite mixture crucible, with automatic temperature control. Our product range includes the following type of furnaces: - Tilting induction furnace - Static open crucible - Static vacuum/controlled atmosphere crucible IKOI's metallurgical process knowledge allows the selection of the most approriate technology and crucible material for each application.

Request for a quote

IKOI SPA

Italy

Induction melting furnace for continuous casting of all the alloys and colours of gold and silver. Fitted with a single or double inductor, and one or more work heads for the production of wire, flat bars, tube and other section on request. All our continuous casting furnaces have an updated microprocessor which can control, set up, memorise and print up to 99 different programmes.

Request for a quote

IKOI SPA

Italy

IKOI provides spare parts and maintenance services on all his equipment, including: Installation Services Preventive maintenance Services Remote Assistance Porcess improvement services Spare parts and consumables We can also provide service and spare parts to your old IECO equiment, thanks to our team of experienced personnel on IECO technology.

Request for a quoteManufacturer/ Producer

Via Monte Verena, 20

36022 San Zeno Di Cassola - Italy

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PLANSEE SE

Austria

Tungrit tungsten granule is available in the Plansee Online Shop. It is an extremely dense granulate with a low specific surface area and a narrow particle size distribution . The granule is the idea choice for chemical analysis or as a balancing mass. Order fast and easily from the producer's online shop: www.plansee.com/shop

Request for a quote

TRADIUM GMBH

Germany

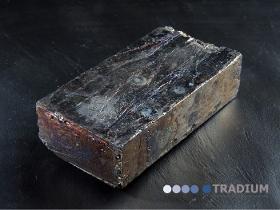

At TRADIUM, gold is available in the following shapes for industrial use: - Gold granules and (investment) bars - Gold in various organic and inorganic compounds Your point of contact for gold is: Philipp Goetzl-Mamba Phone: +49 (0)69 50 50 250 - 236 We are looking forward to hearing from you!

Request for a quote

TRADIUM GMBH

Germany

At TRADIUM, praseodymium is available in the following forms for industrial use: - Praseodymium metal - Praseodymium oxide Your point of contact for praseodymium is: Jan Giese Phone: +49 (0)69 50 50 250 - 237 We are looking forward to hearing from you!

Request for a quote

TRADIUM GMBH

Germany

At TRADIUM, bismuth metal is available in the following shapes for industrial supplies: - Bismuth granules, ingots, metal needles - Bismuth powder - Bismuth oxide Your point of contact for bismuth is: Frank Meier Phone: +49 (0)69 50 50 250 - 234 We are looking forward to hearing from you!

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free