- europages

- >

- Information systems - advice

- >

- INTERLOGIN SOFTWARE GMBH AN- UND VERKAUF VON HARD- UND SOFTWARE

INTERLOGIN SOFTWARE GMBH AN- UND VERKAUF VON HARD- UND SOFTWARE

Germany

Distributor

The company INTERLOGIN SOFTWARE GMBH AN- UND VERKAUF VON HARD- UND SOFTWARE, is a Distributor, founded in 2002, which operates in the Information systems - advice industry. It also operates in the Database acquisition and security industries. It is based in Münster, Germany.

Other companies in the same industry:

Distributor

Zumbuschstr. 22a

48167 Münster - Germany

Company info

Key figures

-

- Company headcount

- 1 – 10

Organisation

-

- Year established

- 2002

-

- Main activity

- Distributor

Activities of INTERLOGIN SOFTWARE GMBH AN- UND VERKAUF VON HARD- UND SOFTWARE

- Information systems - advice

- Database acquisition and security

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

LEAN REŠITVE

Slovenia

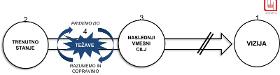

Process optimization - how to get started? Any company that wants to maintain improved processes in the long run must first consider a vision, direction or goal (1). The most effective way to successfully motivate employees is clear communication of vision, direction and goals. Process optimization requires a change in the current way of working, so it is very important for employees to identify with the vision, direction and goals of the company. Once the direction is confirmed and agreed, the current situation needs to be effectively analyzed to optimize the process (2). Understanding the current situation without subjective ballast is the key to effective process optimization. Employees directly involved in the process participate in the analysis of the current situation and systematically present the current situation using lean methods.

Request for a quote

LEAN REŠITVE

Slovenia

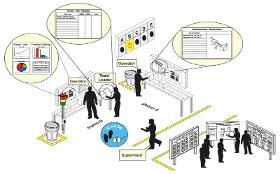

Gemba walk! What is it? The term Gemba walk is derived from Japanese and means “real city” or “crime scene”. At Lean, “gemba” is the most important place for a team, as it is a place where added value is created. It is a very important part of the lean management philosophy. The purpose is to enable managers and managers to observe the actual work process, work with employees, gain knowledge about the work process and find opportunities for continuous improvement. The operator is best aware of all the problems that arise in the work process and is an excellent source of information. Before you start a tour, you need to have a plan that depends on your long-term and specific goals. You can use a checklist of questions to help you clarify the process

Request for a quote

LEAN REŠITVE

Slovenia

SFM-Morning meetings in production (shop flor managment) The system of regular meetings (Morning meetings in production) or SFM is an excellent system that we recommend to all companies for good information transfer. Many factories have set up corners for SFM meetings where workers and their managers can meet. SFM (Shopfloor management) makes it easier for us to manage production processes at the operational level. SFM - Morning meetings in production - main advantages: Raise operational efficiency through standard operations Improved information flow Reduction of errors in the manufacturing process Disclosure of gaps in production or processes. Raising employee productivity Positive effect on RVC

Request for a quote

LEAN REŠITVE

Slovenia

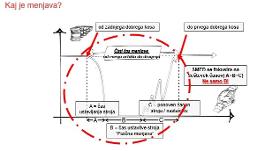

7 losses - in Lean, all activities that consume resources but do not bring any value to the end customer are marked as loss. In fact, they are activities that really create value for customers, only a small part of the overall work process. Everything else can be classified into one of 7 losses. In the original, this is a seven-loss method, we added an eighth, untapped human potential. The types of 7 losses are: EQUIPMENT / DEFECTS EXCESSIVE PRODUCTION UNNECESSARY MOVEMENT TRANSPORT WAITING INVENTORIES EXCESSIVE PROCESSING (PROCESSING) UNUSED HUMAN POTENTIAL

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free