KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

Manufacturer/ Producer

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The well thought-out design, accurate components and robust construction of our Precision Dial Gauge series offer reliability, durability and long working life. The standard features that enhance the quality across our entire product range are: Calibrations of all Dial Gauges are traceable to national and international standards. The final quality control for the whole series includes visual inspection and full mechanical functional tests. Supplied with Declaration of Conformity and Confirmation of Traceability. Materials and components selected specifically to ensure a long working life.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The digital display with its large numerals makes it very simple to use this Dial Gauge. Function and display section can be rotated through 270°. The sturdy construction guarantees precision and reliability. Following functions of the Digital Dial Gauges MD 12T and FMD 12T can be used: Zero setting mm/inch selection Memory set hold Data transmission Réf I / Réf II Preset value recall Selection of measuring direction Selection of Reading (only FMD 12T, FMD 25T) Data request by any ASCII code

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

Most modern methods are applied in the production of our high quality Dial Test Indicators. They are both sensitive and shock-resistant. Here are some of the advantages applicable to the whole series: All features of the models reading up to 1 mm measuring range conform to DIN 2270. This applies to all deviation spans, the measuring force and the hysteresis error of the measuring force Automatic change of the direction of measurement Indication clockwise in all types Precise components, running in ruby bearings, warrant highest precision throughout Precision bearing for the lever shaft Body with 3 dovetail slides for clamping the stem and other equipment Body hard-chromed in order to protect the dovetail slides against damage Tungsten carbide ball 2 mm Ø in measuring inserts Dial adjustable by knurled bezel Supplied in a convenient box with transparent lid with 1 stem Ø 8 mm h 6 and 1 spanner for changing the contact points

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

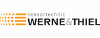

The Comparator Gauges Compika offer a high degree of security and precision. They are based on a solid and well thought-out construction taking into account the latest technology. They are manufactured by the most up-to-date methods. The following quality features characterize our manufacturing programme of Comparator Gauges Compika: Their design conforms to the requirements of DIN 879-1. This applies not only to the dimensions but also to permitted spans of error, hysteresis and measuring pressure. Effective shockproof system Pinions and shafts of the movement are jewelled After removal of the safety cap the adjustment screw on top of the case allows simple and safe zero setting of the instrument over the total measuring range. A safety cap prevents unintentional turning of the fine adjustment facility. Stem and spindle are made of hardened stainless steel. The measuring spindles are very sensitive on account of their accurate guides. Additional overtravel assists with the...

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The base is dull chromed, hardened and lapped. The metal collet attachment guarantees reliable fixing of the dial gauge. An additional internal hexagon screw makes exchanging the dial gauge easier. Each of our mechanical dial depth gauges is equipped with the 10 mm long special contact point 573/21.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

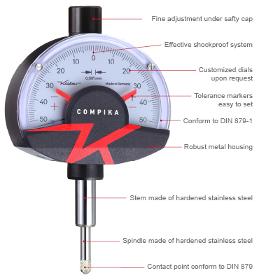

Dial Thickness Gauges are used for measuring the thickness of a very wide range of materials such as leather, paperboard, paper, felt, rubber, glass, sheet, metal, films, plywood and plastics. The shape of the feelers should be adapted to the material being measured. We supply all our Dial Thickness Gauges with contact points type c as standard, unless otherwise stated in our catalogue. Gauges can be supplied with other forms of contact points (a,b,d, or e) at no extra cost.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

The large display has a good visual perception for easy reading of the measuring result. The use of aluminium for the body of the instruments makes them light and easy to handle. The Digital Thickness Gauges are switchable from metric reading to inch reading.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

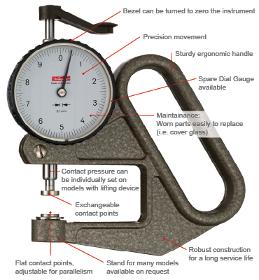

The advantages of having a correctly set saw for all sawing work are well known. By using a Saw Setting Dial Gauge any specified set for various kinds of timber can be exactly maintained, thus ensuring maximum output and efficient workmanship. The method of measuring could not be simpler. The gauge is laid on the saw blade so that the sprung tracer touches the cutting edges of the saw. The pointer gives instant reading of the measurement. As the Gauge has a dial on both sides, it can be used either left or right handed.

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

1. Zero setting of the dial on any flat surface / measuring block 2. The required tolerance range is set on the dial in the normal way. In our example: ±10 3. The measuring operation is carried out very simply by inserting the specimens in the measuring stop 4. Reading of the measurement and the tolerance. The next measuring operation can begin

Request for a quoteManufacturer/ Producer

Hahnstr. 11

78054 Villingen-Schwenningen - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssories use for machines.

Request for a quote

QUELLTECH GMBH

Germany

Laser Scanner Solution: This task is a typical application of the high-resolution QuellTech 2D/3D Q5-880 Blue Laser Scanners. Two of these units are placed at the left and at the right of the measuring objects, at a defined inclination angle. Blue laser light in this case is a prerequisite, as the cast parts are red-hot, hence emitting in the red spectral range. Additionally, the client was in need of a software solution for the project, so a 3D point cloud processing application was implemented, performing inline and evaluating width, height and angle results. QuellTech customer is able to inspect continuously the product quality, simultaneously avoiding scrap. He uses the same system for more than 10 different types of castings. Errors caused by manual inspection are considerably reduced, and safety for personnel is enhanced.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Knight Optical can offer you Plane Mirrors (general, λ/1 and λ/4), for use within 3D Mapping Applications in a range of materials such as Soda-lime float glass, white float glass, and BK7 glass. Plane mirrors also known as front surface mirrors or first surface mirrors are used within 3D Mapping Applications. As stock we hold a number of general purpose, λ/1 and λ/4 with a range of up to 6 types of coatings such as Enhanced Aluminium, Ali/SiO2 and Ali/Mgf2. Our general purpose grade mirrors are made from good quality float glass and generally available in thicknesses of 1mm, 3mm and 6mm as standard. How our mirrors are used within 3D Mapping, is they are used as a sender and receiver of a laser beam that will take a reading of a specific surface, and from that reading it can create a 3D map of the surface that is has read. FOR MORE INFORMATION READ THE PDF..

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free