KASAG SWISS AG

Switzerland

Manufacturer/ Producer

KASAG SWISS AG

Switzerland

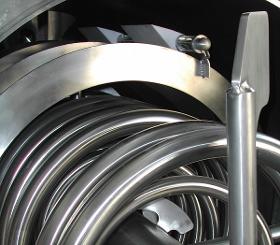

KASAG is a qualified sub-supplier for nuclear technology, for which we have an ASME-manufacturer permit. We process stainless steel and special materials for you corresponding to nuclear standards with regard to material traceability and quality documents. With KASAG as partner, safety comes first. Cryo technology is used for generating extremely low temperatures of under -150°C. Special physical effects can be used in the process for liquefaction and separation of gases. Manufacturing pressure containers for cryogenic temperature applications requires specific welding processes and certified KASAG welding specialists. For even for lowest temperatures KASAG is your first choice.

Request for a quote

KASAG SWISS AG

Switzerland

Nonporous welding and sealing technology are the central criteria for building vacuum chambers and vacuum apparatuses. KASAG has specific knowhow that it has gained over many years as well as a great deal of experience. Comprehensive, internal tests, such as the helium-leakage test, guarantee the absolute leak-tightness of your KASAG products. With KASAG, you remain leak-proof.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG experts are specialists in the construction of kettles, industrial cooking plants for the production of fruit base, vegetables and sauces. Its comprehensive systems that include cookers, coolers, condensers, piping and valves are being built according to current requirements in aseptic design. Preventing product contamination caused by germs in the products is a central concern. This is enabled through optimized equipment design, special bearing and mechanical seals and a functional CIP(Cleaning in Place) facility. We adapt to the needs of each and every new customer and seek to build customized or modular plants that fulfil their requirements to the maximum extent.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG experts are specialists in the construction of cooking apparatuses and industrial cooking plants for manufacturing jam, marmalade, compote and jellies. We are enthusiastic about the combination of high product standards, special standards for pectin preparation, optimal lumpiness of the products and short process times. We adapt to the needs of each customer and build customized or modular systems that fulfil their requirements..

Request for a quote

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

KASAG SWISS AG

Switzerland

Ohmic heating is a gentle, continuous process for heating of products, especially for products to keep their lumpiness, such as fruits, vegetables, spices, and other foodstuffs. Heating occurs via electricity, whereby the product functions as electrical resistor. Compared to the conventional cooking methods, the product is not heated over a hot surface, but, rather, uniformly over the entire cross-section. Using the hot-cold water systems is greatly beneficial, for generating energy efficiency as well as for enhancing process control with respect to the direct use of steam as heating medium. Especially in horizontal mixing systems, hot-cold water systems offer optimal conditions for realising the highest product quality and for preserving the lumpiness of the products. The automatic snap-closing manway is excellently suited to facilitate the frequent opening and closing processes. Owing to the heat and humidity, it is critical to add the additives in the cooking apparatuses through sta

Request for a quote

KASAG SWISS AG

Switzerland

Concepts, heat exchanger for energy recovery Energy dissipation and global warming cause damage to the nature and to the environment and thereby challenge our future. You can do a lot to prevent it. For instance, with innovative concepts and heat exchanger solutions for energy recovery so that water, wastewater, process fluids and exhaust vapours at the source in the building, in the industry, transported in the canalisation to the sewage treatment plan and even in the surface waters can be rendered useful thermally through heat transfer. Apart from the ecological aspects, investments in the realm of renewable energies are economically consequential. With KASAG as your partner for planning, design, engineering, and the construction of heat exchanger plants for energy recovery from waste heat, you are acting in favour of sustainability.

Request for a quote

KASAG SWISS AG

Switzerland

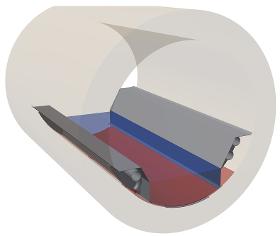

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote

KASAG SWISS AG

Switzerland

The use of energy potential at the place of its origin is optimal. Ensuring the heat transfer in the heat exchanger is thereby a vital criterion and requires customized solutions. The torrent of sewage flow in buildings is collected in a containment volume for generating energy using heat exchanger for heating and cooling. No retention volume is necessary for continuous outflows and process heating. This can be applied, for instance, in apartment buildings, residential buildings, communal buildings, hotels, thermal baths, swimming pools as well as in different energy-intensive industries, such as in foodstuffs, chemicals and pharmaceuticals.

Request for a quote

KASAG SWISS AG

Switzerland

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote