- europages

- >

- Packaging

- >

- LESER GMBH

- >

- products

LESER GMBH - Your packaging supplier from the black forest in Germany!

Germany

Manufacturer/ Producer

LESER GMBH

Germany

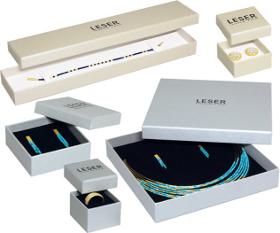

Lift-off cardboard boxes with foam pad inside

Request for a quote

LESER GMBH

Germany

However, we also equip our packaging for writing instruments with individual deep-drawing inlays - here to enclose two pens!

Request for a quote

LESER GMBH

Germany

Particularly popular at present are sustainable writing instrument packaging and writing instrument packaging in sustainable design - contact us to find out more!

Request for a quote

LESER GMBH

Germany

This wide writing instrument packaging in bright orange is suitable for packing two pens!

Request for a quote

LESER GMBH

Germany

Many structure papers are available for the ballpoint pen packaging - Here you can see a ballpoint pen packaging with corrugated structure paper!

Request for a quote

LESER GMBH

Germany

We also produce plastic ballpoint pen cases in many different colours in our production facility in Southern Germany!

Request for a quote

LESER GMBH

Germany

With our writing instrument sleeves you can exclusively pack and give away large quantities of pens!

Request for a quote

LESER GMBH

Germany

Frame frame case for weightless presentation of writing instruments - with our frame case FRAME you present and pack your writing instruments & pens practically weightless!

Request for a quote

LESER GMBH

Germany

Flocked foam inserts are elegant and comparatively soft in their texture - a high-quality variant of the packaging insert for pens!

Request for a quote

LESER GMBH

Germany

Flocked deep-drawing inlays for writing instrument packaging are produced in a highly automated process and individually adapted to your writing instruments!

Request for a quoteeuropages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free