- europages

- >

- Heat exchangers

- >

- MAKINA KAT KAL. PANRAD. VE TEKS. SAN. TIC. LTD. STI

MAKINA KAT KAL. PANRAD. VE TEKS. SAN. TIC. LTD. STI

Turkey

Manufacturer/ Producer

The company MAKINA KAT KAL. PANRAD. VE TEKS. SAN. TIC. LTD. STI, is a Manufacturer/ Producer, which operates in the Heat exchangers industry. It also operates in the Radiators - fin-type industries. It is based in Denizli, Turkey.

Other companies in the same industry:

Manufacturer/ Producer

Akcesme Mah. 2018 Sok. No: 37

Bozburun Yolu

20000 Denizli - Turkey

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Main activity

- Manufacturer/ Producer

Activities of MAKINA KAT KAL. PANRAD. VE TEKS. SAN. TIC. LTD. STI

- Heat exchangers

- Radiators - fin-type

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

NC MANUFACTURING AND ENGINEERING

Turkey

Double tube heat exchangers (also known tube-in-tube) are designed whereby one tube is concentrically positioned within a larger tube. The double tube composition allows for unrestricted flow of product, making it the ideal heat exchanger for viscous products. The product flows through the inner tube and the service fluid flows through the surrounding shell.

Request for a quote

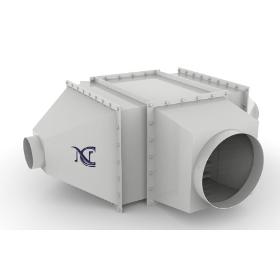

NC MANUFACTURING AND ENGINEERING

Turkey

Recuperator systems are heat exchangers that produce hot air by utilizing the energy of high-temperature waste flue gas generated in furnace systems, boiler systems and various processes. Recuperators various heating needs of facilities such as combustion air preheating and ambient heating are met and energy consumption is minimized. Compared to economizers, they have larger surface area and dimensions at the same heat capacity. They can be manufactured as finned tube and straight tube. Recuperator heat exchangers can be made from numerous materials steel, stainless steel and other special materials.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We are specialized to design and fabricate carbon, stainless or exotic steel pressure vessels mainly for oil&gas, petrochemical and power industries in accordance with ASME Sec VIII Div.1 and EN Norms with CE mark. Most of the industrial processes need to store fluids and materials of different kinds and with different purposes.

Request for a quote

NC MANUFACTURING AND ENGINEERING

Turkey

We design and manufacture products based on the project sent by our customers or according to customer requirements. Calculations, designs and projections according to customer demand and in accordance with ASME Code Section VIII Div 1 and 2 (American Society Mechanical Engineers), API 661, API 650 (American Petroleum Institute), TEMA (Tubular Exchanger Manufacturers Association), AD-MERKBLAATTER, CODAT, DIN, EN 13445, PED 2014/68 / AB and TSE. The most common processes in the Oil & Gas, Petrochemical & Chemical, Food & Beverages and Heavy & Light Industry require a significant number of equipment to exchange heat or to storage different fluids or components. The fluid can be either liquid or gas, and one of each flows into the tube and the other flow out of the tube is used to boil, condense or cooling the fluid.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free