- europages

- >

- Cutting- plastics - machinery

- >

- MASCHINENBAU BARDOWICK GMBH

MASCHINENBAU BARDOWICK GMBH

Germany

Manufacturer/ Producer

Product catalogue preview

MASCHINENBAU BARDOWICK GMBH

Germany

The powder coating machine EPC is designed for the powder coating of cables, hoses and profiles up to a max. diameter of 150 mm and line speeds of up to 1,500 m/min. Our filter cleaning system already patented in 2004 ensures 100% dust-free machine environment. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been the world’s leading manufacturer of these powdering machines for decades. Numerous customer-specific special requirements have been developed and implemented by us. The Advantages of the Powder Coating Machine EPC Safe adhesive forces on the product by using electrostatic powder guns with up to 100 kV. 100 % dust-free machine environment Optional fine dosing for powdering with minimum quantities High efficiency at simple operation, The Powder Coating Machine EPC at a glance Cable Powdering with Highest Quality The application of talcum and other powders as separating agents between the individual layers of the cable is no trivial task nowadays.

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The combined cutting machine CC is designed for the precise cutting of hoses and profiles made of rubber or plastic up to a maximum diameter of 100 mm and at line speeds of up to 300 m/min. A clean cut quality and minimized length tolerances are the hallmarks of our combined cutting system. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Combi Cutter CC Low space requirement through combination of the caterpillar BP and the rotary cutter RC Precise transport speed due to servo axes of the latest generation Optimized cutting length tolerances through specially developed cam application High effectiveness with simple operation The Combi Cutter CC at a glance A cut-to-length system with the highest quality

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The Orbital Cutter has been developed to cut rotationally symmetric, rigid products made of rubber or plastic without chips or deformation. With this cutting concept, no radial forces act to the product, so that there are no deformations. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Orbital Cutter OC Optimized cutting length tolerances through specially developed cutting application Chipless, vertical cut Servo controller of the latest generation Aluminium multilayer pipes can also be cut High effectiveness with simple operation The Orbital Cutter OC at a glance A cut-to-length system with the highest quality The orbital cutting machine OC machine meets your high quality requirements in many aspects.

Request for a quote

MASCHINENBAU BARDOWICK GMBH

Germany

The Rotary Cutter RC is designed for the precise cutting of hoses and profiles made of rubber or plastic up to a maximum diameter of 100 mm and at line speeds of up to 300 m/min. A clean cut quality and minimized length tolerances characterize our rotary cutter. Maschinenbau Bardowick GmbH (formerly DCM Maschinenbau GmbH Lüneburg) has been a leading manufacturer in the field of extrusion downstream equipment for decades. Customer-specific special solutions are developed and implemented by us. The advantages of the Rotation Cutter RC Optimized cutting length tolerances through specially developed cam profile application Servo controller of the latest generation Low space requirement due to compact design High effectiveness with simple operation The Rotation Cutter RC at a glance A cut-to-length system with the highest quality The rotary cut-to-length RC machine meets your high quality requirements in many aspects.

Request for a quoteYour partner for downstream extrusion equipment, specialised machinery and quality-tested welding technology from one source. We have been operating as a team of experts for welding technology and special purpose machines at the Lüneburg site for more than 20 years. Our corporate structure is based on three areas of expertise: Development and production of downstream equipment for extrusion lines like powder coating machines, cooling units, caterpillar haul-offs, cutting and commissioning units. Development and production of special machines and plants as "turnkey", everything from one source. Production of welded assemblies and fixtures as a reactive supplier. The synergies of these areas enable us to offer a wide range of products. One-off production is just as much our business as series or variant production in quantities. Trustable cooperation with our partners, both on the customer side and on the supplier side, is the essential basis for maximum profitability with optimum quality.

Website

Documents

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Year established

- 1984

-

- Main activity

- Manufacturer/ Producer

Activities of MASCHINENBAU BARDOWICK GMBH

- Cutting, plastics - machinery

- cutters for rubber

- shearing machines

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

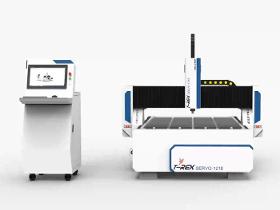

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free