- europages

- >

- Structures- aluminium

- >

- METAWELL GMBH

- >

- products

METAWELL GMBH - metal sandwich technology

Germany

Manufacturer/ Producer

METAWELL GMBH

Germany

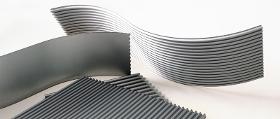

lightweight aluminium panel with 2 cover sheets and a corrugated core very light and rigid (same statical performance than solid aluminium but up to 80 % lighter) high corrosion protection because all aluminium sheets are pretreated with a primer for serial production: cover sheets, thickness of corrugation and surface (on request also powder-coatable) can be customized 100 % recyclable without material separation. In addition, the proportion of secondary aluminium is approximately 90 %. excellent thermal conductivity and good sound absorption absolute flatness high fire protection classifications for different areas production in a continuous manufacturing process simple processing of the material with standard tools Lightweight design with Metawell Metawell is a patented aluminium lightweight panel, which is thanks to its sandwich structure very light and has a high bending resistance. Metawell sandwich panels are perfectly well suited for elements with an appealing surface...

Request for a quote

METAWELL GMBH

Germany

lightweight aluminium panel, where a cover sheet is connected to a corrugated aluminium sheet in a continuous manufacturing process material with highly anisotropic stiffness, resulting in a very simple two-dimensional shaping is possible (see video) simple processing of the material with standard tools high corrosion protection since all used aluminium sheets are pretreated with a primer 100 % recyclable without prior separation of materials. In addition, the proportion of secondary aluminum is approximately 90 %. Easiest forming with Metawell Aluflex Navigation Metawell Aluflex Easiest forming with Metawell Aluflex Design and delivery program Forming parallel to the corrugation Forming vertically to the corrugation Powder-coatable material Video of forming Metawell Aluflex Metawell Aluflex is a material with rigidity levels that depend strongly on the direction. The corrugated sheet is bonded to only one aluminium cover sheet. This structure enables easy 2D-forming and...

Request for a quoteManufacturer/ Producer

Schleifmühlweg 31

86633 Neuburg - Germany