METZNER MASCHINENBAU GMBH - Your Partner for Automation Solutions

Germany

Manufacturer/ Producer

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 1000 is a sensation among the tabletop units. The automatic cutting and stripping machine processes cables, strands and wires up to 9 mm diameter and 6mm² cable cross-section with a special cutting and pull-off force (optional 10 mm², depending on material). The presettings are conveniently made via the modern 12" touch panel, where the operator can define all processes. Thanks to the sensors for diameter and material recognition, the AM 1000 works extremely precisely. Another special feature is the tool-free replacement of guides and rollers. This means that the AM 1000 can be changed over in just one minute. With the extensive interface preparation, the machine can be optimally expanded with peripheral devices and adapts to all customer requirements. The compact design with retractable touch-screen and the low weight of only 28 kg also offer special comfort. This makes the AM 1000 especially easy to transport.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The AM 3000 range of cable processing machines are distinguished by cutting and haul-off power and their convincing modular, robust and long-life construction for continuous industrial working. There are different models with different cutting powers and specifications. To match the processing requirements, numerous knife contours and technologies are available: The patented „ double-knife system“ facilitates different processing in a single working pass, the circumferential rotary technology offers exact circular cutting for cables with very thin or rigid outer insulation cover and for co-axial cables. Every model is equipped as standard with a full set of interfaces for peripheral equipment and IT integration. The machines can easily be converted into complete production lines, thus further increasing the process automation.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The cable processing machines in the AM 3800 range are characterised by their outstanding cutting and haul-off power and their modular, robust and long-life construction for continuous use in industrial applications. These machines outstandingly combine power and versatility. Equipped with cutting power for cables up to 70 mm sectionand 20 mm diameter, they are the ideal solution for an unusually wide spectrum of applications. Depending o the processing demands, numerous knife contours and technologies are available: the patented double-knife system allows different processes to be performed in a single working pass. The circumferential rotary cut offers an exact cutting round cables with very thin or tough insulation outer cover.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner AM 5000 range includes the flagship models for precise processing of thick cables up to 240 mm² section and 35 mm diameter. Even the basic specification models, with their high torque and powerful three-stage step motors offer the highest level of cutting and haul-off power. All models are equipped with as standard with the Metzner double-knife system that enables very varied and multi-stage processes to be performed. Moreover, with convincing operator-friendliness and long service life. Metzner AM 5000 models are also suited to processing thinner braided cables from 1.5 mm² The stripping full haul-off 1side/2nd side amount to 270-450 mm and 90-270 mm, for partial haul-off 450 mm and 270 mm. For interuption-free automatic production, a number of sensors monitor the material feeding If a material blockage occurs, the production stops automatically and the operator is informed about the cause of the fault.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Electrical cabinets contain the electrical and electronic components of a process engineering system, a machine tool, or production equipment that is not directly located in the machine. They are manufactured by special switch cabinet builders or by the machine manufacturers themselves. To save costs, there are automation solutions that are not only worthwhile for large production series, but are also suitable for the more efficient and economical production of individual and small series. Metzner offers a unique and comprehensive system solution to reduce your expenses in switchgear construction. Depending on your requirements, different stripping and crimping machines are available, which differ in terms of design, performance and degree of automation. METZNER TRIATHLON SERIES - for precise cutting to length and one- or two-sided stripping - for crimping the ferrules (single- and double-sided) - for individual labelling of strands with different printing method

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The »All-rounder« with particularly gentle and fine adjustment of the pressure between the transport belts. Ideal for soft and elastic material. The ST-OB is available in Red or Green versions. The Metzner ST-OB is for cutting cables & strands up to 30 mm diameter. Thanks to the gentle adjustment of the pressure between the transport belt also optimal for cutting rubber seals. WIDE SPECTRUM The cut-to-length machines of the ST-OB range have convincing precision, compact construction and processing spectrum for products such as cables, wires, braided cables, shrink-fit tubes, and numerous other materials.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The powerful "universal cutting machine" with superior pulling and cutting strength. The contact pressure between the conveyor belts is pneumatically controlled and opens and closes automatically when the cover is opened and closed. Ideal for solid and dimensionally stable materials. Metzner also offers the Variocut in three “Red – Green – Blue" equipment lines. Each equipment variant is based on the same basic model with the same high-quality mechanical components. The individual models differ in speed, control and the interfaces for peripherals.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Unslotted corrugated tubes are used to protect cable wires and cable harnesses. When cutting this corrugated tube sheathing to length, it is important to cut precisely and reliably on the crest of the wave, to avoid forming sharp cutting edges which damage the in-drawn cable wires. Metzner corrugated tube cutting machines of the CT 4000 series process corrugated tubes with great reliability and precision. Thanks to our many years of experience in processing corrugated tubes, we know the challenges that some corrugated tubes present and are well prepared for them. Our wide range of standard equipment ensures the best possible processing of your corrugated tubes. l The Metzner CT 4200 additionally offers an integrated slitting device for automatic slitting of unslit corrugated tubes. For material diameters from 7.5 mm to 40 mm.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Corrugated tubes are used to protect cable wires and cable harnesses. When cutting this corrugated tube sheathing to length, it is important to cut precisely and reliably on the crest of the shaft, to avoid forming sharp cutting edges which damage the in-drawn cable wires. Metzner revolutionised the cutting to length of slotted corrugated tubes with the SM 4000 corrugated tube cutting machine. It is the only machine in the world that can guarantee a precision cut on the crest of the shaft due to its unique and patented feed and cutting technology. A laser sensor monitors the production and activates the cut precisely and repetitively with up to 8000 cuts per hour. The SM 4000 with its patented "toothed wheel laser system" is the only machine in the world that guarantees twist-proof feed- and cutting technology for slotted corrugated tubes

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Profiles and sealing systems often require ventilation holes or mounting holes. Drilling equipment from Metzner carries out these tasks. We provide the following solutions adapted to your specific requirements: - In-line as an eccentric drilling station for regular drilling at equal distances - In-line as travelling drilling station for drilling at the same or variable distance - In-line as "drilling beam", which carries out all drillings for an entire sealing profile with variable distances in one operation - Off-line for drilling in combination with final trimming The machine is equipped with drilling spindles with very high speeds of up to 60,000 revolutions per minute. An exact drill hole is thus achieved in a short cycle time. The geometry of the drills ensures that the waste falls to the outside.

Request for a quoteManufacturer/ Producer

Messerschmittstraße 30

89231 Neu-Ulm - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

CNC-STEP GMBH & CO. KG

Germany

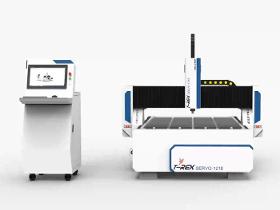

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free