- europages

- >

- Diaphragm compressors

- >

- NOVA WERKE AG - NOVA SWISS

NOVA WERKE AG - NOVA SWISS - Pioneering spirit makes Nova Swiss your ideal development partner.

Switzerland

Manufacturer/ Producer

NOVA WERKE AG - NOVA SWISS

Switzerland

Nova Swiss needle valves offer a high degree of safety and reliability, even under challenging operating conditions. The valves can be installed in both directions and provide an effective seal for both gaseous and liquid media. The heart of the valve consists of a specially shaped valve seat and a two-piece, non-rotating stem. Erosion of the stem is thereby avoided. The pressure-resistant parts are made of high-quality, corrosion-resistant stainless steel. Every single valve body is certified by us. For applications that are subject to particularly strict quality standards, we offer complete traceability of all our pressure-bearing parts. Nova Swiss high-pressure valves are supplied complete with screw fittings.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

High-pressure systems can be automated easily and effectively by using Nova Swiss valves with air-operated actuators. The valve bodies and packing systems are identical to those in the manual valves and provide the same benefits. The extremely robust and reliable air-operated piston actuator is available in two versions: ATO (air-to-open), opens with compressed air. ATC (air-to-close), closes with compressed air.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Nova Swiss extreme-temperature valves for high-pressure and gas applications are designed to operate at temperatures ranging from -200°C to +300°C thanks to a special extension adapter.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

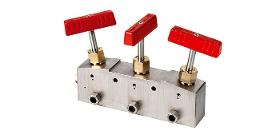

NOVA SWISS block valves with venting (Block and Bleed — BBV) as well as double-block valves with venting (DBV) provide maximum safety in confined spaces. Their design allows measuring instruments and/or pressure gauges to be disassembled in an unpressurized state during running operation. Additional features include a reduction of potential leakage points and the number of screw connections to a minimum. The BBV is available in 1/4" and 3/8" versions, the DBV in 1/4", 3/8" and 9/16". Some of our block valves are also available in custom designs on request.

Request for a quoteGreat companies need outstanding development partners – for what's happening at the moment and for what's yet to happen. NOVA SWISS will work on future-oriented solutions for your products with a pioneering spirit and adaptability. The future is new – the future is NOVA. Take the road to the future with us. NOVA WERKE AG is a Swiss technology company headquartered in Effretikon with subsidiaries in France, Germany and Hong Kong. The company develops and manufactures products under the premium quality brand Nova Swiss in four product lines. Production areas: High-pressure technology, diesel components, surface technology and hydrogen components. Our comprehensive services and high-tech components and processes are designed for demanding applications and meet the most stringent requirements in terms of quality, reliability, standardisation and safety. Our customers and their interests are at the heart of everything we do.

Website

Documents

Manufacturer/ Producer

Vogelsangstrasse 24

8307 Effretikon - Switzerland

Company info

Key figures

-

- Company headcount

- 101 – 200

-

- % of export sales

- 95%

Organisation

-

- Year established

- 1921

-

- Site status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of NOVA WERKE AG - NOVA SWISS

- Diaphragm compressors

- Rupture discs

- Stainless steel unions

- High-pressure valves

- needle valves

europages also recommends

A selection of companies related to the activity:

Request for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free