PASCHAL-WERK G. MAIER GMBH

Germany

Manufacturer/ Producer

PASCHAL-WERK G. MAIER GMBH

Germany

The climbing platform KBK, folding is a working and climbing scaffold which is supplied to the building site ready assembled. After erecting the guard railing post and unfolding the platform, KBK is ready to use and can be dropped into the clevis shoe using the crane.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

PASCHAL Dam bracket is used wherever single-sided climbing is required, for example for reservoir dams, port and harbour constructions, lock-up constructions in inner city projects and refurbishment measures. The formwork panels can be tilted in fully variable positions on the dam brackets in both directions, allowing for ideal adjustment to the full range of wall slopes and wall abutments. All working platforms remain horizontal while the formwork is tilted.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

Lifting platforms are used as working platforms and for raising and moving inside formwork for elevator shafts and staircase cores as well as other structures where normal climbing units cannot be used because of the lack of space. The PASCHAL klik-klak beams are a modular component system which can be adjusted to all layouts.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

GASS is a further development of the commercially available aluminium shoring systems. With a maximum safe working load of up to 140 kN per leg, this is the aluminium shoring system with the greatest load-carrying capacity.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

The shoring frames TG 60 are made of steel tube of higher strength and are stiffened with 2 small diagonal braces. To transfer tensile forces, every frame is secured by hinged pins, locking pins or bolts to each other. In this way the towers can be assembled on the ground and placed by a crane. The shoring frames TG 60 are designed symmetrically – because of that you don’t have to care about the direction of the diagonal braces.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

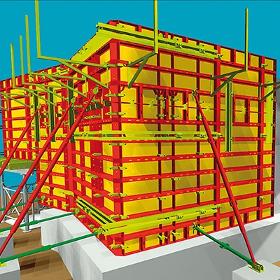

PASCHAL formwork planning for the next generation for the planning with BIM technology. PPL assists building contractor’s work preparation department so that the use of formwork can be planned in an optimal way. The warehouse module shows the available equipment necessary for realisation of the planning. The additional equipment to be provided for construction in due time will be shown too. The interface to the PASCHAL AR app makes it possible to use in mobile form on the construction site.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

PASCHAL-Plan was created on the basis of the AutoCAD architecture. The layouts of this product can be entered into AutoCAD, or, alternatively, loaded from existing drawings. The formwork plans are then generated from predefined formwork elements. The plans generated in PPL can be edited and loaded into PASCHAL-Plan pro, with the panels and accessories being positioned at predefined locations. The connection and tie materials are automatically calculated, while users can work on the layout directly in various views. The construction sites are simplified, while the clear 2D drawings are generated after using this product, which can contain information that is relevant for the present task. Next, the detailed representations in 3D show the layout of various accessories and elements and the colored graphics help users understand the drawings.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

PASCHAL Ident technology provides a unique electronic number to every formwork element,quite similar to a human fingerprint. Through this process, one is guaranteed with unmistakable and unique identification which is a pre-requisite for credit processes or for leasing. RFID technology has three essential components - the reader, the transponder(a computer chip with an antenna and casing) and the software that is associated with the reader. Data associated with the formwork element is transmitted online from the reader to the PC, or directly to the online portal.

Request for a quote

PASCHAL-WERK G. MAIER GMBH

Germany

Thanks to real-time monitoring, PASCHAL Maturix facilitates the efficient concreting process and, at the same, time provides well-founded evaluations. Based on the real-time analysis of the concrete strength, the optimal time for dismantling is determined. As a result, the number of defects due to early dismantling is reduced on the one hand, and, on the other hand, there are no unnecessary waiting times during the concrete maturity phase. The user receives a convenient notification as soon as the target value has been reached or if there is too much difference in the internal temperature. In order to guarantee the best possible concrete quality, the concrete temperature can be controlled and adjusted from any location by means of heating and cooling systems.

Request for a quoteManufacturer/ Producer

Kreuzbühlstr. 5

77790 Steinach - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures formworks for tunnel constructions and secondary lining works. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures formworks for tunnel constructions and secondary lining works. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

AAAGILER GMBH

Germany

Discover the versatility of circular formwork for the construction of circular concrete walls with or without clamping points. With this innovative circular formwork for concrete for radii from 3 m, you can efficiently realise construction projects such as biogas plants, silos, tunnel entrances, storage basins, sewage treatment plants, adventure pools, towers or stairwells.

Request for a quote

AAAGILER GMBH

Germany

Formwork for piers and bridge girders plays a crucial role in the construction industry, especially in the realisation of bridges and other large concrete structures. With customised solutions, complex architectural designs can be realised while ensuring structural integrity and safety. Customised formwork systems for bridge piers offer numerous advantages for construction professionals. Not only do they allow precise customisation to the specific requirements of each project, but they also enable efficient and time-saving construction.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free