PERO AG

Germany

Manufacturer/ Producer

PERO AG

Germany

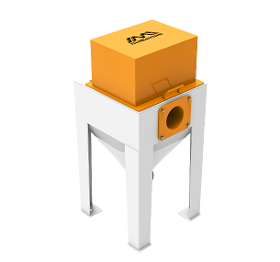

The R0 has been specifically designed for intermediate and final cleaning of small and extra small parts. Thanks to its universal process technology, the R0 offers operators unrivalled cleaning performance in an extra compact machine. The R0 can be transported through door clearances of as little as 1,000 x 2,000 mm. Depending on the model, the cleaning unit can be loaded from the long or from the short side. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Top quality cleaning in compact unit Short cycle times High throughput Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The modular, preassembled PERO S1 units are available at short notice for your specific application The compact S1 degreases and cleans components made from various materials and of many different geometries and degrees of machining. The S1 is designed for dirt and grease removal at low energy and resource consumption. It therfore is the ideal entrylevel unit for cleaning with solvents in a closed system. The integrated distilling unit ensures process safety and efficient cleaning at a consistently high level. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; other solvents on request 530 x 320 x 200 mm or 530 x 365 x 250 mm Entrylevel mpdel for cleaning with solvent in closed system Configurable for short cycle times Vapour degreasing in 1st process step Available as 1bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The modular, preassembled PERO R1 units are available at short notice for your specific application The cleaning units of the R1 series are renowed for their high performance. They offer short cycle times with reproducible cleaning results. The tried and tested process technology behind the R1 meets the highest quality standards in parts cleaning. Operation under vacuum protects the medium, reduces energy and solvent consumption and allows for short cycle times. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit 480 x 320 x 200 mm or 530 x 320 x 200 mm (std.) 530 x 365 x 250 mm (A chamber) Fast and economical High performance Reproducible cleaning results Available as 1, 2bath and 3bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

The modular, preassembled PERO N2 units are available at short notice for your specific application Thanks to its highly efficient process technology and low energy consumption, the N2 offers excellent cleaning results and high throughput. Operators can choos from a range of solvents in order to achieve best cleaning results for their specific tasks. The energy manager function enables operators to control the heating output for maximum energy efficiency. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Standardised and strong High efficiency High throughput combined with ourstanding cleaning quality Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit Hall trolley

Request for a quotePERO AG – an innovative partner in industrial parts cleaning for more than 66 years! Pero's high-performance machines de-oil, degrease and clean workpieces in the individual stages of the production sequence and provide defined corrosion protection. A cleaning procedure which is optimally tailored to workpiece surface and material removes impurities caused by the production process – and reliably provides the required degree of technical cleanliness. The cleaning task is defined and the optimal cleaning procedure is developed in collaborative partnership with the user – always with consideration of their individual production processes and their benefit. More than 180 Pero employees ensure the highest technical standards and provide objective and expert advice. We would be happy to invite our Pero competence centre with Pero parts cleaning systems, to present alternative parts cleaning options.

Website

Documents

Company info

Key figures

-

- Company headcount

- 101 – 200

-

- Sales staff

- 1 – 10

-

- % of export sales

- 45%

Organisation

-

- Year established

- 1953

-

- pages.epage-home.site-status

- Registered office

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Activities of PERO AG

- Cleaning machines, industrial

- Systems for precision cleaning

- industrial washing machines

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The part washing machine is designed to easily clean dirty parts with a small size and complex structure in the shortest time possible. Thanks to its brush, the person performing the washing process can carry out any kind of cleaning in the dirty part in detail. It is an ideal parts washing machine for using in small areas.

Request for a quote

EC PLAZA

South Korea

As the world’s global leader in semiconductor equipment manufacturing, VISION SEMICON has cease-lessly worked with the management philosophy of merging future-oriented technology with today’s technology in hopes of providing happiness and contentment for all humans. As the result, VISION SEMICON has received reviews from clients worldwide for its plasma treatment process equipment, which is the most important procedure in semiconductor production process, oven system and unmanned semiconductor production process.

Request for a quote

CRYOSNOW GMBH

Germany

• For large surfaces and stubborn contaminations • Powerful round nozzles • Flat nozzles with blasting widths of up to 100 mm (4") • Available as Desktop and Trolley • No power supply, as driven pneumatically

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to clean jet filter bags that lose their filtering function over time due to dust particles

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free