PLANT OF AGRICULTURAL MACHINERY - Innovative grain cleaners, grain throwers and grain loaders. New grain processing technology

Ukraine

Manufacturer/ Producer

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain loader with a large hopper PZM-170B is intended for unloading grain from grain carriers and trailers directly into the hopper of this grain thrower and subsequent loading of granaries to a height of up to 9 meters. Grain loader PZM-170B is also successfully used for loading grain carriers, trailers, wagons, ships, containers and trucks. The size of the hopper is 3.12 meters wide, 1 meter high with a lowered front wall, and a volume of about 4 cubic meters. It is convenient when handling grain in ports, grain warehouses and other premises, or in open areas. Self-propelled grain loader with a large hopper PZM-170B is used in the following sequence: grain loader PZM-170B drives up to the loading point on its own; the hopper is lowered into the working position and rests on the surface of the warehouse; a car, a loader or a tractor with grain drives up to the hopper; the loader throws grain through a special guide pipe to a height of up to 9 m and up to 25 m in lengt

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

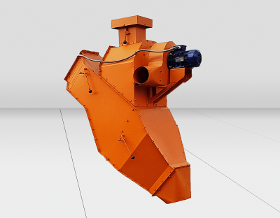

The powerful PZM-170 grain thrower has productivity up to 170 tons per hour. With its help it is possible to carry out quick loading of grain into grain carriers, cars, railway cars, containers, barges, trailers, etc. The grain thrower PZM-170 also quickly loads and unloads both low and high grain stores. Another important function that the PZM-170 can perform is the transfer of grain in closed warehouses and in open areas. This is necessary for long-term storage of grain. In the process of grain transfer, its moisture content and contamination by light impurities are reduced. Main advantages of using grain throwers: - versatility - used for loading any transport, storage of any grain in piles up to 9 m high; - energy efficiency and gentle handling of grain; - ability to move by itself and load itself with grain without help of other machines or people; - easy and convenient for people operation and maintenance; - reliable construction with the use of available components.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Instead of a dust separator and a pneumatic conveyor, a cyclone is installed on a self-moving OBC-25CB grain cleaner, and a hopper instead of scraper feeders. The volume of the hopper of the OBC-25CB grain cleaning machine is about 1 cubic meter. OBC-25CB grain cleaner cyclone collectsdust, straw and light impurities. As a result, personnel can work without respirators and dust does not settle on already cleaned grain, people and equipment. The hopper of the OBC-25CB grain cleaning machine allows the grain truck to unload grain directly into the hopper, and not onto the floor. As a result, grain trauma, energy consumption and wear of the OBC-25CB loading conveyor are reduced. You can also load grain into the OBC-25CB hopper with a screw, noriya, loader, etc. Grain cleaning in OBC-25CB is carried out by adjustable air flow and sieves, which allows to obtain high quality cleaning. You can also purchase an OBC-25CB grain cleaner with a hopper and scraper feeders.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

In the self-propelled grain cleaner ОВС-25D, cleaning is carried out not on 8, but on 9 sieves. The presence of an additional sieve allows better separation of pure grain and impurities. An additional sieve is installed in the housing of the auger of feed waste and divides them into two parts by size. Due to this, the ОВС-25D grain cleaning machine divides the grain into 4 fractions, and not 3 as ОВС-25 with 8 sieves. ОВС-25D has a capacity of up to 25 tons per hour. ОВС-25D, like other models of ОВС-25 grain cleaning machines we produce, is a self-propelled machine. ОВС-25D independently rides and loads itself with grain without the help of other mechanisms or personnel. Loading is carried out by a chain elevator, which is located in front of the ОВС-25D and picks up grain at a width of 5.3 meters. Grain cleaning in ОВС-25D is carried out both by regulated air flow and sieves, which allows to obtain high quality cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25C self-propelled grain cleaning machine with a cyclone is the latest innovative development. Main advantages of using the OBC-25C: 1. Versatility - used for cleaning any kind of grain and seeds. 2. High quality cleaning and minimal damage to the grain. 3. Move independently and load themselves with grain without help of other machines or people. 4. Can independently load transport up to 3 meters high. 5. Easy and convenient operation and maintenance. 6. Capacity up to 25 tons of grains per hour. OBC-25C with a cyclone is the best self-propelled technique for high-quality and high-performance cleaning of grain, heap, cereals, legumes, oilseeds, corn, sorghum, sunflower, rape from impurities in open areas and in warehouses. You can also choose the model of the OBC-25C grain cleaning machine with an extended elevator, frequency converter, remote control, lighting, bumper, hopper, screw loader. OBC-25C is an ideal machine for cleaning grain.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

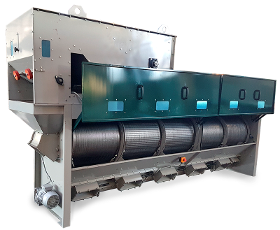

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The AS-60 air separator is used when cleaning grain to separate dust and light fractions from the grain. It can be used for different types of cereals, for example, for wheat, durum wheat, corn, rye, soy, oats, buckwheat, millet, rape, rice, as well as for sunflower, peas, chickpeas, beans, cocoa beans, etc. Cleaning grain from dust and light impurities ensures its long-term storage and helps to prevent various potential threats. Due to the unique design of the cascade type, the AS-60 air separator provides high quality cleaning of grain from dust and light impurities. Air speed and grain feed are very easy to adjust with 3 handles. This allows you to adjust the separation settings at any time depending on the properties of the grain being cleaned. Due to its simple, effective design and wide adjustment range, the AS-60 air separator has many applications. This separator can be used separately, installed in stationary grain cleaning lines or used as part of mobile grain cleaner.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The OBC-355 universal grain cleaning separator is the most multifunctional drum-type machine for cleaning grain in the world. The number of operating options for the OBC-355 grain cleaning separator exceeds 50. The multifunctionality of the OBC-355 drum cleaner allows it to be used to separate and calibrate a wide range of products (for example: a mixture of any grain, grain with very high clogging, corn with very high humidity, cotton fibers and seeds, glass balls, etc.). The OBC-355 grain cleaning machine can be used both for high-quality calibration and for preliminary cleaning with large volumes of processing. Multifunctionality is achieved due to the innovative design of OBC-355, consisting of a large number of flap valves, screws and 2 main parts: an aspiration unit that removes light impurities depending on the air flow controlled by the regulation of aspiration; cleaning and calibration unit with a rotating drum that removes small and large impurities

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The MPO-50M machine carries out quick preliminary cleaning of grain , legumes, oilseeds and industrial crops, corn, sorghum, rapeseed, sunflower seeds and grass. Designed for operation as a part of stationary production lines of grain cleaning complexes. Preliminary cleaning of grain in MPO-50M is carried out according to two main parameters - size and aerodynamic properties . The advantages of MPO-50M are that it is a universal high-performance machine for quick pre-cleaning of any grain or seeds with a moisture content of up to 70%. MPO-50M can easily cope even with the cleaning of grain heavily clogged with straw and other impurities. High speed of operation increases production volumes per unit time and allows you to quickly move from the stage of preliminary preparation of raw materials to the next stage in order to better preserve seeds and grain, prepare them for drying and active ventilation, increase the efficiency of subsequent cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

3BC-20A grain cleaning machine performs the following functions: - eliminates dust and light trash using a powerful integrated suction system; - using 16 sieves installed in the machine, it carries out high-quality cleaning of grain heaps from large and small impurities, debris, chopped grain and separates the grain into fractions. 3BC-20A is a reliable and popular grain cleaning machine, which is successfully used for cleaning cereals, legumes, oilseeds, corn, sunflower, sorghum, rape, coriander and many other crops. With the help of 3BC-20A, even very contaminated grain can be effectively cleaned to produce a quality product. 3BC-20A is a universal grain cleaning machine that can operate in three modes: in pre-treatment of grain with a capacity of up to 50 tons per hour; in primary grain cleaning mode with a capacity of up to 25 tons per hour; in the calibration mode of grain for seeds with a productivity of up to 12,5 tons per hour.

Request for a quoteManufacturer/ Producer

Tsentralnaya str., 12b

51030 Kitaygorod - Ukraine