POREX TECHNOLOGIES GMBH - Making the world safer, healthier and more productive.

Germany

Manufacturer/ Producer

POREX TECHNOLOGIES GMBH

Germany

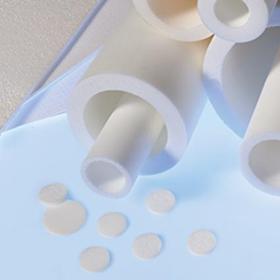

A comprehensive porous material solution As a complete porous materials solution, POREX® bioprocessing media provide critical functionality and performance in single-use bioprocessing applications. Our bioprocessing media and filters: Are robust and easily incorporated using common techniques such as press-fitting, heat-staking and ultrasonic welding. Ensure performance, accuracy and reproducibility–Certified Pure POREX™ materials and filters are rigorously tested and qualified by independent analytical, clinical and life cycle microbiology laboratories to help insure the purity demanded in bioprocessing applications. Comply with regulatory standards–POREX ® bioprocessing media and filters are USP Class VI, Gamma sterilization and TSE/BSE compliant. Applications Include Spargers Prefilters Wicks Vents Tangential flow filters Floating filters Formats Available Sheets Tubes Complex three-dimensional structures Material Offering Advanced porous materials (PE, PP) Porous PTFE...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

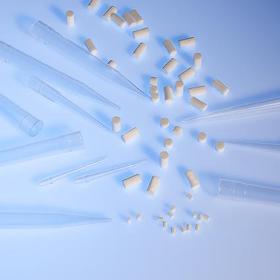

Enhance semiconductor processing with pure materials Our high-purity diffusion tubes allow semiconductor processing facilities a precise way to diffuse, filter and distribute process gases. Specifically designed to precise flow and dimensional tolerances, POREX® diffusion tubes: Ensure purity –Material is backed by the Certified Pure POREX™ program of independent laboratory testing of leachables, extractables and interfering substances. Deliver precise flow rates and tolerances–Engineered for tight pore size and volume control. Improve process effectiveness–Design is customizable per application requirements. request sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Excellent performance with porous vacuum componets Manufacturers around the world trust our porous materials to deliver excellent performance when used as vacuum components. Anti-static additives can also be introduced for applications that require conductivity. Ensure purity–Material is backed by the Certified Pure POREX™ program of independent laboratory testing of leachables, extractables and interfering substances. Deliver precise flow rates and tolerances–Engineered for tight pore size and volume control. Improve device effectiveness–Design is customizable per application and can incorporate anti-static properties. request sample ask an engineer

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

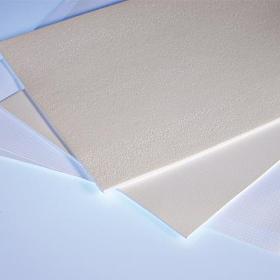

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Optimize performance with advanced powertrain vents Porex has a wide variety of venting solutions for powertrain applications. Our sintered POREX® Virtek™ PTFE can be an effective venting material for hydraulic and other systems that require low-level breathability. Directly weldable to numerous plastic enclosures, POREX® Virtek™ PTFE can ensure the proper functionality of your system. Our POREX Virtek™ PTFE is a robust sintered PTFE venting material that resists oils and water while allowing ventilation.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater efficiency high performance separation media Our oil separation media feature a unique bonded fiber technology that can perform the function of multiple layers of traditional filter media, efficiently separating oil mist from the air stream. Our bonded fiber can also separate water from diesel and other fuels. With its gradient density structure, our reliable, efficient media can replace several layers of traditional media used in water separation. Specifically designed to reduce vehicle emissions and to improve performance, our powertrain filters come in two different types of solutions that can be provided in both custom and standard options: Our unique bonded fiber structure can efficiently separate over 95% of oil mist from oil reservoir fumes. Efficiently removes water from fuel streams that can cause issues with injectors and engines Increase efficiency, as POREX ® media can perform the function of multiple layers of traditional separation filter media request...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Protect automotive fluid reservoirs For automotive fluid reservoirs, manufacturers trust POREX hydrophobic and oleophobic PTFE vents and fiber media filters. Compared to competitive products, our vents: Feature robust POREX Virtek™ PTFE – Pure PTFE media is extremely hydrophobic. It features high temperature resistance and can be directly welded to caps or enclosures. Can be customized – Self-supporting filter media can be customized into many shapes.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

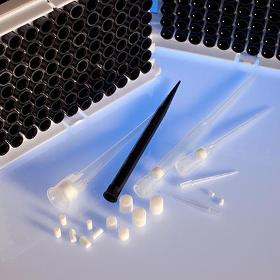

Greater protection from aerosols and aspirated liquids Our new FORTRESS™ Pipette Tip Filters offer a liquid-sealing barrier devoid of any contaminates or additives that can cause PCR, molecular, or analytical methodology and protocol issues. Specifically designed to protect the sample and the pipetter from harmful aerosols generated during the pipetting process or from liquid aspirated into pipette tips, our filters: Ensure purity –Non-leachable and extractable sample recovery is backed by the Certified Pure Porex™ program of independent analytical, clinical, and life science testing. Protect sample integrity–Seals out aerosols and liquid contaminates while preventing cross-contamination and sample carryover. Improve accuracy and precision–Design is optimized for maximum consistency in air flow, form, fit, and function across a broad spectrum of pipetting volumes.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximum consistency in airflow, filter purity, and aerosol containment POREX® Automation Certified Pipette Tip Filters are customized and optimized to meet the fit, air flow, and volume placement of your specific robotic and automated liquid-handling instruments, sample processors and dispensing systems. To streamline laboratory operations and production, these automation and robotic pipette tip filters are backed by the Certified Pure Porex™ Program and: Maximize air flow –Delivers optimal dispensing and pipetting performance across a wide range of liquid volumes. Prevent cross-contamination–Eliminates aerosol bypass and sample carryover. Increase sample throughput–Provides tighter tolerance control for increasing laboratory workflow and reducing instrument downtime.

Request for a quoteManufacturer/ Producer

Industriestrasse 21

02692 Obergurig, Ot Singwitz - Germany