- europages

- >

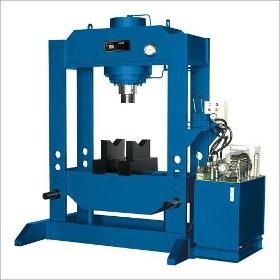

- Presses- hydraulic

- >

- REHA MAKINA

REHA MAKINA

Turkey

Manufacturer/ Producer

The company REHA MAKINA, is a Manufacturer/ Producer, which operates in the Presses, hydraulic industry. It is based in Karatay Konya, Turkey.

Other companies in the same industry:

Manufacturer/ Producer

Fevzi Cakmak Mah. Astim San. St. 10753 Sok. No.20/F

42050 Karatay Konya - Turkey

Company info

Key figures

-

- Company headcount

- 11 – 50

Organisation

-

- Main activity

- Manufacturer/ Producer

Activities of REHA MAKINA

- Presses, hydraulic

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF briquetting systems of the Biomass series process dust, shavings and wooden chips into briquettes of consistently high quality and density. Varying bulk densities are offset automatically during the process. These materials can be pressed into a compact form without the use of binders. It is important that the moisture content of the chips is below 15%, preferably under 12%, and that the chip size does not exceed 50mm. The general rule is that the finer the material is, the smoother and more solid the surfaces and edges of the resulting briquette. The systems can be equipped with a multitude of options, thus optimally adapting them to customer needs. This series offers maximum flexibility. All systems are extremely energy efficient thanks to the innovative RUF hydraulic system. Depending on the model, the machines are equipped with motors ranging between 4 kW and 90 kW. The throughput capacities of the RUF Biomass presses range between 50 and 1,300 kg/h.

Request for a quote

DELTAFLUID

France

A flow straightener greatly reduces disturbances in a flow while a conditioner reduces disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe. Thus, these devices make it possible to reduce the upstream straight lengths and to improve the measurement accuracy in the case of a flow measurement. They are therefore to be positioned between a pipe fitting (elbow, reduction, etc.) and a flow measurement element while respecting the distances specified in the standard.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free