SCHÖPP-SPORTBODEN GMBH

Germany

Manufacturer/ Producer

SCHÖPP-SPORTBODEN GMBH

Germany

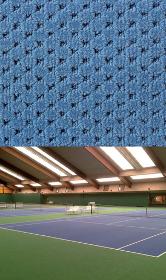

In 1999, Schöpp-Sportboden GmbH launched the Slide quality, the first textile tennis floor with a loop structure, an absolute product innovation on the market. The revolutionary advantage of this generation of surfaces was that the larger amount of granules required for playing with profiled tennis shoes is held much better thanks to the pronounced loop structure. The distinctive rubber structure ensures even gliding behaviour when playing with profiled shoes! In 2010, we further developed the structure of our structured loop granule surface. The new herringbone structure Winner is characterised by a particularly coarse structure for an even more sustainable, uniform granule distribution and very sand-like ball bounce properties. With a yarn count of 1,000 g/sqm and 256,000 N/sqm, proven on approx. 1,000 Slide and Winner pitches, SCHÖPP® Winner has an extremely high-quality tuft construction.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

The classic smooth velour flooring dominated the market for performance-oriented tennis surfaces until the 1990s. It was made from a special tennis yarn with filament thicknesses of 30-40 dtex (fibre cross-section). The further development of tennis rackets over the last 20 years has fundamentally changed the game of tennis. The development of rackets has made it possible for recreational players to accelerate the ball considerably. Today, the tennis surface has to slow the ball down more and allow it to bounce higher. The very fast classic velour has almost completely disappeared from the market in most countries as a result of the changed requirements for tennis surfaces. On the other hand, the structureless and unfilled surface is favoured by performance-oriented tennis players. With this clientele in mind, the latest development from Schöpp is a very coarse-fibre velour flooring with a single filament thickness of 200 dtex!

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

The sliding surfaces used in the past had a number of weak points, which can be attributed to the granules used: Quartz sand is too hard and destroys the base coverings very quickly, while the various rubber granules are too soft and too uneven in shape, so that they in turn are ground up relatively quickly. Both sliding media are controversial due to the dust they generate and bring with them unpleasant side effects such as breathing difficulties, discolouration of clothing and a great deal of cleaning work in the tennis hall and social areas. A new manufacturing process has made significant progress possible: Perfect-Glide tennis granules are not ground from a block of rubber like conventional granules, but are spun into threads using an extruder and then cut to a defined length in a cooling bath. This process enables the production of fine, dust-free extruder micro-granules in a new, optimised lens shape.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

We have installed SCHÖPP® Allround structured velour on around 2000 courts since 1994. It can be played on both with and without our Perfect Glide extruder granules, recommended with treadless tennis shoes. Due to its versatility and its very "honest" ball bounce characteristics, it is equally appreciated by all classes of players. From 1994 to 1998, this product was produced with 750 g/sqm. Since then, a pile weight of 1,000 g/sqm has proved its worth. However, the yarn weight can be increased to 1,250 or 1,400 g/sqm on request. This makes the fabric surface even more compact and durable. What is particularly important here is that the higher yarn insert weight leads to a higher pile density of up to 300,000 pimples/sqm and only marginally to a higher pile height, which would have a negative impact on ball bounce behaviour! A higher yarn weight is by no means an equivalent substitute for our highly elastic, filler-free polymer coating!

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

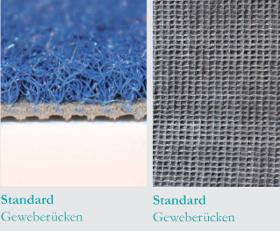

The new generation of fabric backing After the carpet raw material has been tufted and dyed in the colour desired by the customer, the tennis floor is given the necessary nap binding and stability by the back coating. With the classic latex coating, the yarn binding and the coating with a textile secondary backing (action back) are achieved using a highly chalk-filled latex dispersion. This makes the carpet relatively heavy and stiff. With this coating technology, the elasticity only comes from the yarn layer, which is also the wear layer. This means that tennis floors with a classic woven backing become harder year after year, particularly in the main running areas that are subject to the most wear. There is no sustainable elastic layer.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

Like SCHÖPP®Pro-Bounce, SCHÖPP®-Champion is produced from a particularly coarse and robust polyamide yarn with a single filament thickness of 200 dtex. Due to the greater pile height of 6 mm and a lower filament density, the surface is less aggressive than that of the "textile hardcourt". The comfortable SCHÖPP® Champion is therefore primarily aimed at amateur and club players. Its ball bounce is slow, similar to a sand court. Topspin and slice are slightly softened. Thanks to the very robust surface construction, this surface can also be played on with profiled tennis shoes without granules. With the optional granule infill of 400 g/sqm Perfect Glide extruded granules, the SCHÖPP® Champion is reminiscent of a needled nonwoven velour. For several decades, velour needlefelt floor coverings with granulate infill have proven their worth as tennis floor coverings. These surfaces were made of 100 % polypropylene fibre.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

Back in 1978, Ralph Schöpp KG was the first manufacturer to produce a smooth velour surface for an indoor tennis court - since then, more than 2000 velour courts have been installed. The experience we have gained over this period enables us to offer you a truly perfect product today - SCHÖPP®-Classic. A yarn weight of 1000 g/sqm and a pile density of 244,000 pimples/sqm guarantee a surface quality that can no longer be surpassed in terms of sports functionality and durability. sporty, fast ball bounce in the comfort version, high rubber elasticity with good rating comfort life expectancy of approx. 15 years depending on the intensity of use elegant, cosy velour look

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

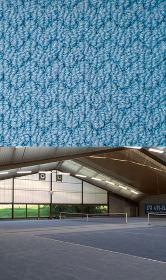

Since 1999, we have also been manufacturing ball catcher curtains in-house, which perfectly match the colours of the two-tone tennis surface and give an old tennis hall a new look. The ball catcher curtains are customised in our factory from high-quality polyester fabric (fire class B1). They are hung with snap hooks on a steel cable. Refurbishing your tennis hall with a two-colour tennis surface and ball catcher curtains on the rear eaves walls - and on the gable walls if required - gives you the opportunity to implement completely new colour concepts and to make your customers aware of the refurbishment measures by means of a new hall appearance with an eye-catching effect. In addition to their functionality and good looks, ball catcher curtains also offer advantages in terms of acoustics and thermal insulation.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

The combination of our very comfortable tennis surfaces (point elasticity) with a sprung floor substructure (surface elasticity) certainly offers maximum force reduction! Hall operators can advertise that their choice of sports flooring offers the maximum in terms of joint protection and force reduction! On the other hand, a sprung floor only develops its comfort when there is a lot of movement. Players who only move a little therefore feel no additional comfort! In terms of ball bounce (flatter) and general playing behaviour (e.g. acoustics), sprung floors are a matter of taste. As a rule, however, players quickly get used to the changed playing conditions. A compact sprung floor can be installed on top of the existing tennis floor covering, provided the surface is level. There is no need to remove and dispose of the old floor covering! If the surface needs to be refurbished, the bonded tennis floor can be removed.

Request for a quote

SCHÖPP-SPORTBODEN GMBH

Germany

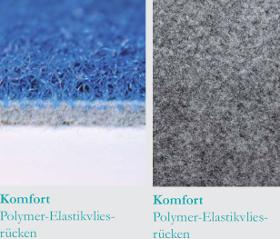

Polymer coating - a pioneering coating technology The comfort version of our tennis floors offers maximum elasticity thanks to a polymer coating with a 400g PES elastic fleece. The 2mm thick elastic fleece layer provides additional playing comfort - you walk like on clouds! However, the special thing about the elastic fleece polymer coating that we have been using since 2011 is not even the elastic fleece, which we have been offering as a comfort backing since 1994, but the completely new coating technology of our polymer coating introduced in 2011.

Request for a quoteManufacturer/ Producer

Am Weidenbroich 3

42897 Remscheid - Germany