SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD. - Expertise in Liquid Bottling Equipments

China

Manufacturer/ Producer

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. Application It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The piston filler is one of the main product of Npack, most of Npack liquid filling dispenser are applying in the fields of Daily chemicals, cosmetics, Food&beverage,personal care products, pharmaceuticals, Oils products.As piston filling machine are solely based on conventional volumetric technology, these are easy to operate and relatively low cost for the majority of the end-use industries. Piston filling machine is one of the most popular liquid filling machine for its universal ability ,piston filling machine can fill thick and highly viscous products, such as chunky, semi-paste, paste products, also extensively utilized to fill chemical preparations, such as adhesives, greases, epoxies, waxes, and lubricant oils, also an optional for filling thin liquid Widely application of liquids, such as viscous liquid, shampoo, lotion,cream;Food sauce;foamy liquid,hand liquid soap,detergent. High Performance and accuracy,easy operation.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machines are made of high-quality stainless steel, making them durable and easy to clean. 6. Automatic control: Liquid weighing filling machines have automatic controls that detect when the container is full, stopping the filling process. 7. Cost-effective: They are cost-effective

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

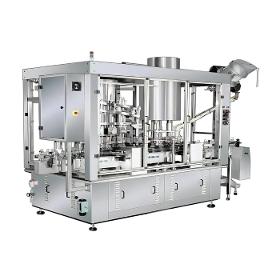

An automatic rotary piston filling machine is a type of volumetric liquid filling machine used to fill liquids into bottles, jars, or containers at high speeds. It operates by using a rotary motion to move the containers through a series of stations, where each station performs a specific function in the filling process. The filling process involves filling the liquid into the containers accurately and precisely using a piston mechanism that is driven by a rotary motion. The liquid is metered out using the piston, which moves in and out of a cylinder to fill the desired volume of liquid into the container. Once filled, the containers are then moved to other stations to complete the filling process. Some of the benefits of using an automatic rotary piston filling machine include increased efficiency, accuracy, and speed, as well as reduced labor costs and waste. These machines can be used for a wide range of liquid products

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life. Dense material, water absorption as low as zero; very high surface finish, minimal friction; therefore minimal residual materials. Thermal expansion coefficient is small, piston clearance fit more, filling accuracy can be achieved online cleaning and sterilization.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Reasonable Design: Designed with a high-quality filling head Easy to Operate: Add the filling material to the hopper, adjust the filling volume, then use the handle switch to control and finish the filling. Standard filling nozzles with OD4MM and OD8 mm, suitable for most of the products specification. Comfortable handle which helps improve user more easy operation The filling volume is adjustable by a mechnical screw, easier and faster Parameters The filling system is piston volumetric and are operated by manual ,efficiently accurate filling with high speed. Filling speed: 10-50 times/min Filling Volume: 5ml to 50ml Hopper capacity: 10L Net weight: 10KG 304SS construction

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Semi automatic Pneumatic volumetric Piston Filling machine is available with Single Head or double filling Heads.High quality and famous brand air cylinder ensure the machine work stably and fast.Make the machine suitable for fill viscosity and liquid.This semi-auto machine have 2 working mode for operation,auto and pedal. Feature Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life.

Request for a quoteManufacturer/ Producer

No.2009 Xupan road, Jiading disctrict

201808 Shanghai - China