SIM AUTOMATION GMBH

Germany

Manufacturer/ Producer

SIM AUTOMATION GMBH

Germany

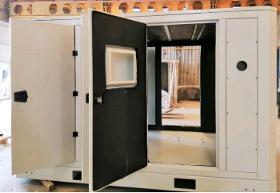

- Entire system solution from a single source - from construction of the laser cell to integration of your chosen KEYENCE laser - self-contained and high-performance solutions for laser labeling small batches of individual parts Versions: - Compact - Rotary - Plus - Classic - Mini - Set up: directly on a desk or mounted onto the movable base frame - Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: - focal point to be freely set and is especially impressive - marking laser follows various shapes - easily switch between different heights (± 21 mm = 42 mm) - mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field (depending on the type of laser): between 120 x 120 mm and 330 x 330 mm.

Request for a quote

SIM AUTOMATION GMBH

Germany

Lightweight composites and composite materials offer substantial benefits in aviation – above all, they are lightweight yet also safe and cost-effective. Whether large engine parts or smaller components, all are very important when it comes to safety. Both must then be assembled using extremely reliable and precise machines – which is one of the core skills at SIM Automation GmbH. Whether supplier codes, components, serial numbers, approvals or manufacturing dates, suppliers in the aviation industry handle complex assemblies with a great deal of data that has to be recorded. You have the option of managing traceability via a work instruction or by using a laser cell from SIM Automation GmbH. Laser marking cells realized by us for the marking of: - Combustion chambers - nameplates

Request for a quote

SIM AUTOMATION GMBH

Germany

- Quality control and safeguarding - Individual test values and criteria - Customer-specific measuring and testing plants - Single measuring systems with manual assembly - Fully integrated and automated testing plants using robots - Optical, acoustic or electrical systems with/ without parts contact, data preparation, analysis Measuring and testing systems we were involved in: - Camera systems with corresponding image processing - Part recognition, positioning, color and surface examination, checking for damages - Optical / tactile / ultrasonic tests using sensors and displacement measurement systems - Leakage and pressure tests - Inspection and monitoring of filling level - Run-out properties and accuracy - Backlash measurement - Electrical tests and measurements - Electrical values, check measurements, switching and opening properties Used in all branches: e.g. pharmaceuticals industry, medical engineering, cosmetics, electronics and automotive industries.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - autonomous driving - electromobility - connected car - electric pumps - operating elements - door locks - instruments - airbag inflators and igniters - gearboxes Development of part-feeding systems and test systems. Assembly and inspections lines that we've already developed: - Airbag inflators - Intercoolers - Oil pumps - Door and trunk locks - Instrument components - Vehicle components for driver assistance systems - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines we have been involved in: - Lighting components (H7 / Xenon / LED) - Safety belt height adjuster - Heatable windscreen washer jets Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SIM AUTOMATION GMBH

Germany

Some requirements are so specific that this is a job for our special machine construction department. Particularly complex processes can be automated with special machines. In some cases, our specialist expertise is also required to make adjustments to series-produced machines and plants. Whether feeding technology, devices and components, laser cells or support and assistance for other mechanical engineers or engineering companies, our SIM concept shows just why individuality is our strength. After all, while there are different optimization scenarios in every branch, it is special machine construction where particularly creative cross-industry expertise is required above all. With our knowledge of the branch, you have come to the right place. Products manufactured using special machines from SIM: — Pens — Food packaging machines

Request for a quote

SIM AUTOMATION GMBH

Germany

Hoppers and belts are the most important part of a production line. While they aren’t used for production themselves, they are a great help in a finely tuned system and significantly optimize the timings. Stop and go is not the watchword, but instead non-stop. Belt hoppers, caches and conveyor belts are all particularly gentle with the product and can be integrated into an existing plant system without any problems. Other advantages of our belt hoppers: - for stock parts for feeding and sorting systems - Extension of replenishment intervals for the operating staff - Dosed allocation of parts - Gentle feeding of parts - Optimization of conveying characteristics on feeder devices - Reduction of feeder device size - Reduction in space needed for part allocation We offer the following small conveyor belts: - With one or two tracks - With deflection rollers or knife edge - With AC/DC motor - Various lengths, scaffolding widths and straps

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM feeding and sorting systems ensure the reliability of our assembly, testing and inspection systems. We develop, design, manufacture and adapt these systems based on customer specifications and the existing assembly system. A combination of various feeding, handling, camera and sensor systems, robots can be used in additional to individual systems. The systems are used in virtually all industrial branches, including medical engineering, pharmaceuticals, food and cosmetics, the automotive industry and electrical engineering. Feeding systems are an important part of automation technology, as are the isolation and provision of individual components. In addition to simple feeding systems, complex testing, measuring and assembly processes can be added without any problems. Different feeding systems can also be combined thanks to the use of robots and handling systems. In this way, we create a seamless transition from simple part feeding through to compact feeding and testing cells.

Request for a quote

SIM AUTOMATION GMBH

Germany

SIM Automation, your partner in - IV catheters - dialyzers - drip chambers - lab-on-a-chip systems, used for various diagnostic analyses and processes in the laboratory on a single chip Assembly and inspection plants in medical engineering that we have been involved in: - Fiber and panel membrane filters - Syringe and infusion systems - Tablet storage and packaging - Flacons / Flacon caps - Lipstick and mascara containers - Coronary testers / rapid blood tests - Sterile caps / membrane seal systems - Components for inhalers - Surgical disposable razors Testing and inspection lines for: - Pacemakers - Dialysis filters Hygienic design is also important here. Back in 2008, we established a clean room in line with Class C / ISO Class 7 requirements in our manufacturing facilities specially for this application area.

Request for a quote

SIM AUTOMATION GMBH

Germany

Small parts in large quantities? Electrical engineering in particular requires very quick machines. Electrical engineering is also becoming increasingly important in IT, with particularly small components required here. The machines from SIM Automation GmbH can detect even the smallest deviations of mere millimeters during sorting. We have produced assembly and testing lines for the following components in electrical engineering (extract): - Instrument components - Step motors and servo motors - Quick-release clutch systems - Gearbox balance shafts (for checking run-out accuracy and backlash) Assembly lines: - Plug contacts (vehicle electrical systems) - Industrial sockets and switches - Sockets / light switches - Electric heater control valves - Electric razors - Electric toothbrushes Testing and inspection: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quoteManufacturer/ Producer

Liesebühl 20

37308 Heilbad Heiligenstadt - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quote

PERGEL METAL

Turkey

Bespoke, Tailormade Electrical Distribution Board With 3 mm Galvanized Steel, Swing Frame, Dual Powder Coated.

Request for a quote

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quote

PERGEL METAL

Turkey

POWER SOLUTION, UPS, SHEET METAL, POWER, GENERATOR, BOARD, LAZER CUT, PANEL, METAL CUTTING, LAZER CUTTING, CNC CUTTING

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free