- europages

- >

- Repairs - industrial equipment

- >

- KELTEKS

- >

- Solidian Connector Staple Anchor

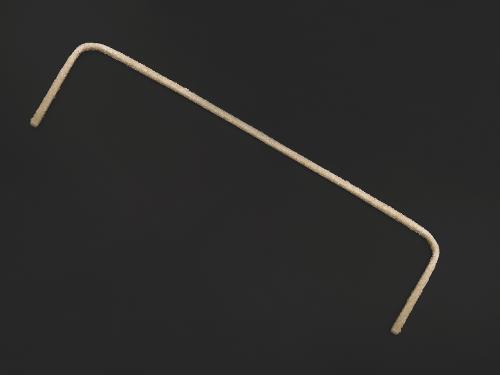

Solidian Connector Staple Anchor

Crack Repair

Description

The solidian Connector Staple Anchor offers the restoration of use and functionality of concrete elements by a simple crack repair. In addition to purely aesthetic aspects, a permanent solution for the successful repair of cracks in almost any concrete element is of particular importance. As a result, the solidian Connector Staple Anchor is the perfect solution for both, a forcefit and limited elastic crack repair resp. reinforcement. A convincing argument for the solidian Connector Staple Anchor is the combination of an affordable but highperformance and easy to install product. a costefficient but effective solution with less material and labor effort durable and maintenancefree crack bridging/stitching with highperformance glass fiber composite

- Repairs - industrial equipment

- Garage Floor Repair

- Crack Repair

- Concrete Floor Repair

Product characteristics

- Material

- Glass Fiber

Similar products from KELTEKS

KELTEKS

Croatia

The solidian Connector Staple Anchor offers the restoration of use and functionality of concrete elements by a simple crack repair. In addition to purely aesthetic aspects, a permanent solution for the successful repair of cracks in almost any concrete element is of particular importance. As a result, the solidian Connector Staple Anchor is the perfect solution for both, a forcefit and limited elastic crack repair resp. reinforcement. A convincing argument for the solidian Connector Staple Anchor is the combination of an affordable but highperformance and easy to install product. a costefficient but effective solution with less material and labor effort durable and maintenancefree crack bridging/stitching with highperformance glass fiber composite

Request for a quote

KELTEKS

Croatia

The simple connection of masonry parts to an effective bond, which can be achieved with little effort, is the main focus of the carbonbased solidian WALL CRACK ANCHOR. Cracks in (masonry) façades as well as in the area of openings and (arched) lintels can be repaired efficiently and economically with only minimal interventions in the masonry. Regardless of the possible cause of cracks, they represent significant influences on the overall system of a building and should therefore be repaired with a durable solution. In this context, the structural reinforcement (needling) of masonry structures to restore their serviceability or maintain their stability is also possible.

Request for a quote

KELTEKS

Croatia

The simple connection of masonry parts to an effective bond, which can be achieved with little effort, is the main focus of the carbonbased solidian WALL CRACK ANCHOR. Cracks in (masonry) façades as well as in the area of openings and (arched) lintels can be repaired efficiently and economically with only minimal interventions in the masonry. Regardless of the possible cause of cracks, they represent significant influences on the overall system of a building and should therefore be repaired with a durable solution. In this context, the structural reinforcement (needling) of masonry structures to restore their serviceability or maintain their stability is also possible.

Request for a quote