TRANSFLUID® MASCHINENBAU GMBH

Germany

Manufacturer/ Producer

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

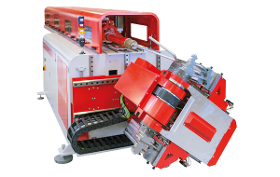

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

All the options in one single machine forming, cutting, postbending cutting, threading. Our rotational technology increase the possibilities of forming on tubes with minimal expenditure on tools. All the drives are servoelectric by design and, if needed, CNCoperated. In our SRM typeforming machines, all the settings are preloaded, so there is no longer any need for costly adjustments. Different tool variants further expand the processing possibilities for chipless cutting or postbending cutting. The machines can produce internal and external profiles and can also roll in synchronicity thanks to a special tool head (inside/outside).

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Powerful and fast forming. The type UMR tube forming machine uses smart operating technology with many preset settings that can be retrieved automatically to achieve perfect mirrorlike surfaces. When producing flaring with 20°90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools the machine can also close tube ends.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quoteManufacturer/ Producer

Hünegräben 17-24

57392 Schmallenberg - Germany