UNIFY THREAD ROLLING

Taiwan R.O.C.

Manufacturer/ Producer

UNIFY THREAD ROLLING

Taiwan R.O.C.

Specially designed for tubular processing. Equilateral triangle supports running to assure the roundness. Equilateral triangle supports rolling for improving roundness, concentricity and vertical degree. Driving by hydraulic unit: Featuring in easy operation and powerful pressure. The transmission gear with grinding shape: Featuring in noise-free, durable and precise transmission. Particularly applied to the tubular thread processing, such as oil connectors, bicycle, automobile and motor vehicle parts, radiating pipe etc.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-16 Thread rolling machine is setting with the vibration bowel. The working pieces are feeding to the between of the two thread rolling dies, after the thread rolling process, the working pieces are automatically loading off from the UM-16 thread rolling machine.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The robotic arms are setting in the between of UM-50A thread rolling machine.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-16 hydralich thru feed thread rolling machine set with the long bar feeding syste, this say up-grade the capacity, and save the labor cost.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

UM-3D set with the vibration feeding bowl which is suitable for thread rolling set screws, wooden thread screws, and any less short screws are suitable. It is a very good method for saving labor cost.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The superior tool steel is a very important element of thread rolling dies. SKD11 (JIS) and 1.2379 (DIN) are the named raw material which we have chosen for the past years. The blank of thread rollingd ies are heat treated by Japanese TECHNO vaccum & oil quenching furnace by heat treating dep. (TOYOGEN INDUSTRIAL CO.,) It will render the higher rigidity and higher wear-resistance of thread rolling dies. After the heat tratment progress, the thread rolling dies are ground by Swiss REISHAUER thread grinding machines. And another progress of tempering to reduce the grinding stress is necessary for thread rolling dies. The thread rolling dies are ready for sale after the quality exam. The good quality of thread rolling dies is able to offer higher precision, longer working life, and reduced the cost to customers. We also produce the thread rollingd ies for other brands thread rolling machines. Your special specifications and requirements are very welcomed.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

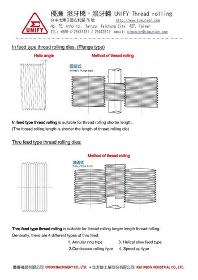

In feed (Plunge) thread rolling dies: There are multiple starts (helix angle) at the edge of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling of shorter length. the thread rolling progress as: Place a work piece in between of thread rolling dies, the screws are formed by strongly pressing progress, when the right thread rollign die returns, take out the work piece. (the work piece stays at the same rollng point). Thru feed thread rolling dies: The threads are as the rings on the surface of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling longer length of screws. (longer then the length of thread rolling dies) The threading progress as: Set the helix angle with the roller shafts of thread rolling machines first, and insert the thread rolling dies. 1. Place a work piece in between of thread rolling dies, make sure the work piece is clamped by thread rolling dies. 2. The work piece is moving

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

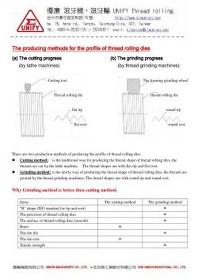

Specification: There are 2 producion methods of producing the proflie of thread rolling dies: Cutting method: is the traditional way for producing the thread shape of thread rolling dies, the threads are cut by the lathe machine. The thread shapes are with flat tip and flat root. Grinding method: is the newly way of producing the thread shape of thread rolling dies, the threads are ground by the thread grinding machines, teh trhead shapes are with round tip and round root. Why we choose the grinding method for UNIFY thread rolling dies, please check the above for the reason. Currently, we have more then 10 units of REISHAUER thread grinding machines (Swiss made) in our factory. The thread rolling dies offered by UNIFY are always the grinding type. The higher level quality can be ensured!

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

In respect of rolling the serration type working pieces as the transmission shafts of autobobile/motor-vehicles, spline shaft, and manual tools. The grinding type serration spline rolling dies can be ensured for the precision, delicate and smooth surface, extending the life of the rollers.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The knurling die: The knurling pattern with non-skid and attracting in appearance on manual tools (straight knurling pattern or diamond knurling pattern) by the knurling dies. The knurling pattern is formed by gear hobbing machine before the heat treatment process, the precision is less good as the grinding type, but, the straightness, and concertricity can be assured.

Request for a quoteManufacturer/ Producer

No. 118, Fengli Rd., Tantzu Dist.

427 Taichung City - Taiwan R.O.C.

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

SPIROL

Germany

This versatile tool is ideally suited for low to moderate levels of production for assemblies that require installation forces up to 22.2 kN (5,000 lbs). The Model PMX Extra Heavy Manual Pin Inserter easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. This Extra Heavy Duty Manual Pin Inserter will provide smooth operation, repeatability and durability.

Request for a quote

SPIROL

Germany

An accurate and consistent method to install virtually any Compression Limiter into plastic applications requiring up to 4.5kN (1000 lbs). Install just one Compression Limiter into one assembly, or several Limiters across multiple assemblies simultaneously for increased productivity. The Model CP’s quick-change tooling creates the flexibility to adapt the platform to a variety of products within seconds. The Model CP has a 230mm x 280mm (9”x11”) work area and is built on a rigid steel frame with high-precision shafting and linear bearings resulting in smooth operation, precise positioning, repeatability, and durability. The Model CP is available with optional enhancement features for error-proofing and maximum efficiency.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

Flexibility in chemical, food, cosmetic and pharmaceutical production. With only one machine, different products and product quantities can be produced with the most suitable tool. The tool shaft can be easily disconnected from the drive, e.g. for cleaning, while continuing to work with a second shaft. The tool shaft has a shaft bearing separate to the motor, which is driven via a plug connection. The possibility of adding a mobile lifting stand offers additional flexibility. Batch sizes from 5 to 1,000 l are covered by the X50, X100 and X200 series. The X100/X50 adapter enables an X100 to be used to produce batches ranging from 5 to 1,000 l. By simply exchanging the shafts, it is possible to conduct jet mixing, mixing dispersion, dispersion, powder aspiration and wetting. Maximum flexibility creates investment security - short set-up times and easy handling.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL inline dispersing machines work according to the rotor-stator system. The dispersing machine is suitable for the production of suspensions, solutions and emulsions in the chemical, food, pharmaceutical and cosmetic industries. Due to the close radial gap between rotor and stator and the high circumferential speed of the rotating rotor, very large shear gradients are generated. The product enters the shear zone through the slots between the rotor teeth and leaves it again via the stator slots. Due to the multi-tooth configuration of rotor and stator, additional mechanical forces act on the product to be dispersed. The product is guided through a rotor-stator system. The liquid is highly accelerated by the inner rotor ring, is completely decelerated at the stator ring and then accelerated again to maximum speed via the next rotor ring. In this way, solid particles and/or droplets are effectively comminuted and homogeneously distributed.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free