- europages

- >

- Flour milling - machinery and equipment

- >

- VOMM IMPIANTI E PROCESSI SPA

VOMM IMPIANTI E PROCESSI SPA

Italy

Manufacturer/ Producer

VOMM IMPIANTI E PROCESSI SPA

Italy

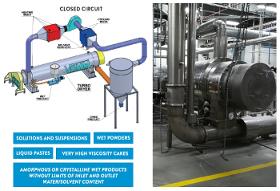

Turbo Dryer operates with any type of wet solid, liquid or pasty product, independently of its moisture content, viscosity and consistency. Turbo Dryer is widely used for partial or full drying in water or solvent precence. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quote

VOMM IMPIANTI E PROCESSI SPA

Italy

Thermal and hydrothermal treatments are used in food industry in order to develop different properties of food for specific applications. These treatments modify properties of cereal flours, germ, bran, starches, fibers, pulse and their derivates. All VOMM thermal treatments in food sector are completely natural, without chemical addition. They are used to produce “CLEAN LABEL” products. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quote

VOMM IMPIANTI E PROCESSI SPA

Italy

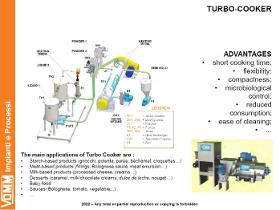

Cooking is the most important process for food preparation. It shall respect the health regulations avoiding in teh mean time the modification of the nutritional and organoleptic properties of the product. VOMM Turbo Cooker allows to obtain a product perfectly homogeneous and constant in the time. VOMM process, compared to traditional processes, takes short residence time and permits to control perfectly the temperature. The particular design of the plant facilitates a simple and efficient cleaning procedure at the end of the production cycle, achieving the highest hygienic standard using hot or cold washing with water and water detergent (CIP system). The high speed and the mechanical action of the turbine optimize the cleaning action of detergents and anti-bacteria products. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quote

VOMM IMPIANTI E PROCESSI SPA

Italy

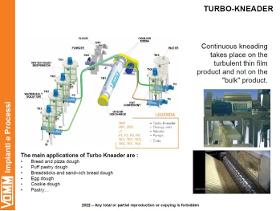

Using VOMM Turbo Kneader it is possible to prepare, automatically, any kind of dough for bakery and confectionary industries. The dough is produced in few minutes in a continuous way, ready for the next processing step, allowing a constant production overtime, avoiding the lossing period of the traditional batch system. Continuous VOMM Turbo Kneader is suitable for any dough with different rheological properties, according to the customer’s requirements. The particular design of the plant permits a simple and efficient cleaning procedure at the end of the production cycle, achieving the highest hygienic standard using hot or cold washing with water and water detergent (CIP system). The high speed and the mechanical action of the turbine, optimizes the cleaning action of detergents and anti-bacteria products. Pilot plant is available in VOMM R&D department in Rozzano.

Request for a quoteSince 1969, VOMM manufactures continuous industrial plants based on its own Turbo Technology for food, chemical and environmental sectors. Turbo-Dryer for solid, liquid or pasty products. It operates on open process gas circuit (flours, polymers, salts, oxides…) or closed one (municipal sludges, refinery by-products, tannery sludges…). It is suitable for drying sensitive products (milk derivatives, thermoplastic polymers…). Special version is available for solvent recovery. Turbo-Concentrator for reaching the concentration limit of the product. It operates under vacuum for sensitive products (whey, permeate…). Turbo-Reactor for pre-gelatinized flour, toasting, roasting, in special de-bittering/de-flavouring process for pulse derivates, synthesis (Bordeaux mixture, gypsum, calcium phosphate salts…), vulcanisation, chemical starch modification… Turbo-Granulator for agglomeration producing compact, resistant, free-flowing, spherical particles. Turbo-Kneader for any dough production. Turbo-Cooker for production of gnocchi, sauces, creams, meat or vegetable filler production... Turbo-Pasteurizer for food projects (baby-food, flours…) and environmental one (biosolids in full compliance with US-EPA Class A standard). VOMM HTS is used for hospital waste sterilization. Finally, VOMM manufactures its own Kiln for Waste-To-Energy projects of sludge drying and incineration. Headquarter is in Milan area. Branch offices and sales agents are all over the world to assist you.

Website

Documents

Manufacturer/ Producer

Via Curiel 252

20089 Rozzano - Italy

Company info

Key figures

-

- Company headcount

- 101 – 200

-

- Sales staff

- 11 – 50

-

- % of export sales

- 80%

Organisation

-

- Year established

- 1969

-

- Site status

- Registered office – Parent company

-

- Main activity

- Manufacturer/ Producer

Business info

Trading areas

- International

Delivery areas

Activities of VOMM IMPIANTI E PROCESSI SPA

- Flour milling - machinery and equipment

- Driers, industrial

- plant and equipment for drying sludge and sewage

- kneading machines for bakeries, biscuit factories and pastry-making

- cooking preparation systems and equipment for the food and canning industry

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

Pellet mill’s working principle is, mash feed is forced outward through holes in a ring die by the action of two or three rollers, which is then cut to a predetermined size. Before mechanical process, steam can be injected into the conditioner at temperature 85 degrees celsius. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

The pellet crusher is a crusher specially designed to break 03-5mm granules into small pieces. With this design, the quality of pellet feed and pellet feed is improved. It is mainly used for poultry and fattening pellets and aquaculture pellets. The pellet crusher has two rollers, the working distance of which can be adjusted (manually or by motor). Thanks to the specially designed abilene rollers, all kinds of grains are processed with high capacity and quality. These rollers can always be used correctly to ensure high efficiency. The roller mechanism is fed regularly by the power supply unit. The pellet is evenly distributed over the entire surface of the roller. Thanks to a regular feeding with this mechanism, a homogeneous structured feeding with a low power and a lower dust content is obtained without overloading the machine. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free