WITTE PUMPS & TECHNOLOGY GMBH

Germany

Manufacturer/ Producer

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pumps of the CHEM series are used as a modified version as submersible pumps for emptying drums and containers. For example, chemicals such as liquid sulphur are pumped at temperatures up to 150 °C. The series is well suited to transfer low-viscosity media at relatively high pressures. — For viscosities up to 1.000.000 mPas — Temperatures up to 500 °C as special version — Differential pressures up to 120 bar — Suction pressures from vacuum to 15 bar Submersible suspension pumps are designed in such a way that the pumps are submerged in the container with the medium and the medium is sucked in via the flangeless suction side. The medium then enters the process from the tank via a pipe from the discharge side. Submersible suspension pumps are often made of special or stainless steels. A special feature of these pumps, as a rule no additional seals are required on the pump. Only the tank is sealed towards the atmosphere.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Witte chemical pumps are used as dosing pumps for a variety of fluids. Pumps of the CHEM series are designed and assembled exclusively at the Tornesch site, thus guaranteeing highest reliability and quality. For all our series we offer a comprehensive spare parts service on request. In addition, we also install the pumps directly at our customer's plant. Dosing pumps of the CHEM series are extremely flexible in their design and can be offered in various variants and equipment thanks to a modular system. Differential pressures up to 120 bar, suction pressures vacuum up to 15 bar Temperatures up to max 500 °C in combination with a magnetic coupling. Viscosities up to 1.000.000 mPas or higher Components made of stainless steel, ceramic and special materials Flow rates from 20 l/h to 170,000 l/h

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Chemical pump with electrical temperature control. The CHEM series is designed to be easy to maintain. Separate pump covers allow a quick inspection of the inner workings from both sides of the pump. To adjust the axial clearance we use shims which can be varied according to process parameters. Chemical pumps of the CHEM series are offered as standard versions with components made of stainless steel or as special versions with coated or ceramic materials. To bring or maintain the pump at process temperature, two temperature control variants can be used, electric and hydraulic.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

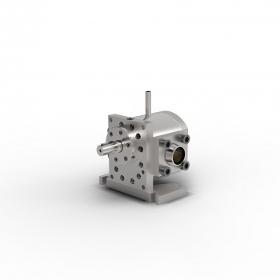

The CHEM gear pump series was developed especially for the requirements of the chemical industry. The series is used for pumping and transferring low to medium viscosity media. The CHEM series is extremely flexible in its design and areas of application. Technical details: — Suction pressures from vacuum up to 15 bar and suction pressures with magnetic coupling up to 25 bar — Delivery volume 1.28 cc/rev to 12,000 cc/rev — Temperatures up to 300 degrees — As special pumps for the chemical industry according to customer specifications — Viscosities up to 1.000.000 mPas

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel metering gear pump for the delivery of chemical raw materials for the production of pharmaceutical products. CHEM metering pumps are also used to pump isocyanate, sulphuric acid, polyol or essential oils. With the appropriate combination of materials, many critical applications can be realized and a variety of low-viscosity fluids can be pumped. The range of applications extends from classic transfer and metering tasks in the chemical and pharmaceutical industry to the pumping of monomers, oligomers and prepolymers in polymer production. These chemical pumps are suitable for even the most difficult tasks and impress with their reliability and dosing accuracy in both vacuum and high-pressure applications. Typical applications for this pump type are in the chemical, cosmetics, food, petrochemical and polymer industries

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Stainless steel gear pump for the delivery of alcohols, isocyanates or gels. The exact volumetric dosing of this series guarantees a low-pulsation and constant flow rate. Due to its compact size and high precision, the CHEM MINI is ideally suited for use in laboratories. Parts in contact with the medium can be made of stainless steel or ceramic materials. The series is available in sizes from 0.2-9-5.5 to 2.95-14-28, other sizes are also available on request. The range of application covers classic transfer and dosing tasks in the chemical and pharmaceutical industry. Due to decades of design experience and optimum material selection, this pump type is suitable for even the most difficult tasks and convinces by its reliability and dosing accuracy in vacuum applications.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Dosing pumps Dosing pumps are used in a wide range of applications, such as in the production of fibres. Synthetic man-made fibres are becoming increasingly important. They are needed for many different applications such as textiles, linen, bristles etc. WITTE metering pumps ensure that the polymer melt is delivered evenly and reliably to the appropriate points in the process. In order to guarantee a constant quality, a constant flow rate is very important. But also in other applications, media with very low viscosities can be pumped safely and precisely. High efficiency and a long service life are the hallmarks of this pump series.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

EXTRU - Melt pump for extrusion and pressure increase of medium to high viscosity media. The extrusion gear pump is mainly used in combination with extruders or kneaders. It reduces the natural pulsation of the extruder and compensates for fluctuations in delivery, especially in single screw extruders. The extrusion pump is used as a melt pump. It builds up the required feed pressure, which is needed for the downstream die. The pressure build-up in the gear pump can be much more efficient than in the extruder itself. The extruder is relieved by using an extrusion pump. Furthermore, considerably less energy or heat is introduced into the polymer. The melt pump thus contributes to conveying the product as gently as possible. The EXTRU is indispensable for the production of precise films or micro pellets.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quoteManufacturer/ Producer

Lise-Meitner-Allee 20

25436 Tornesch - Germany