What is important - and what can be ignored?

The first question is: Which supplier is compatible with my needs? As a rule, you will check out several candidates when choosing a supplier. It is therefore important to break down the respective offers to a level of detail that makes them comparable. You can simplify this process by assessing the criteria based on their importance: if you are keen to position yourself as an expert or market leader, the price may, for instance, be less important and only contribute a weighting of 20 percent, while the innovation potential would be 80 percent in this case.

The key indices for the assessment of suppliers

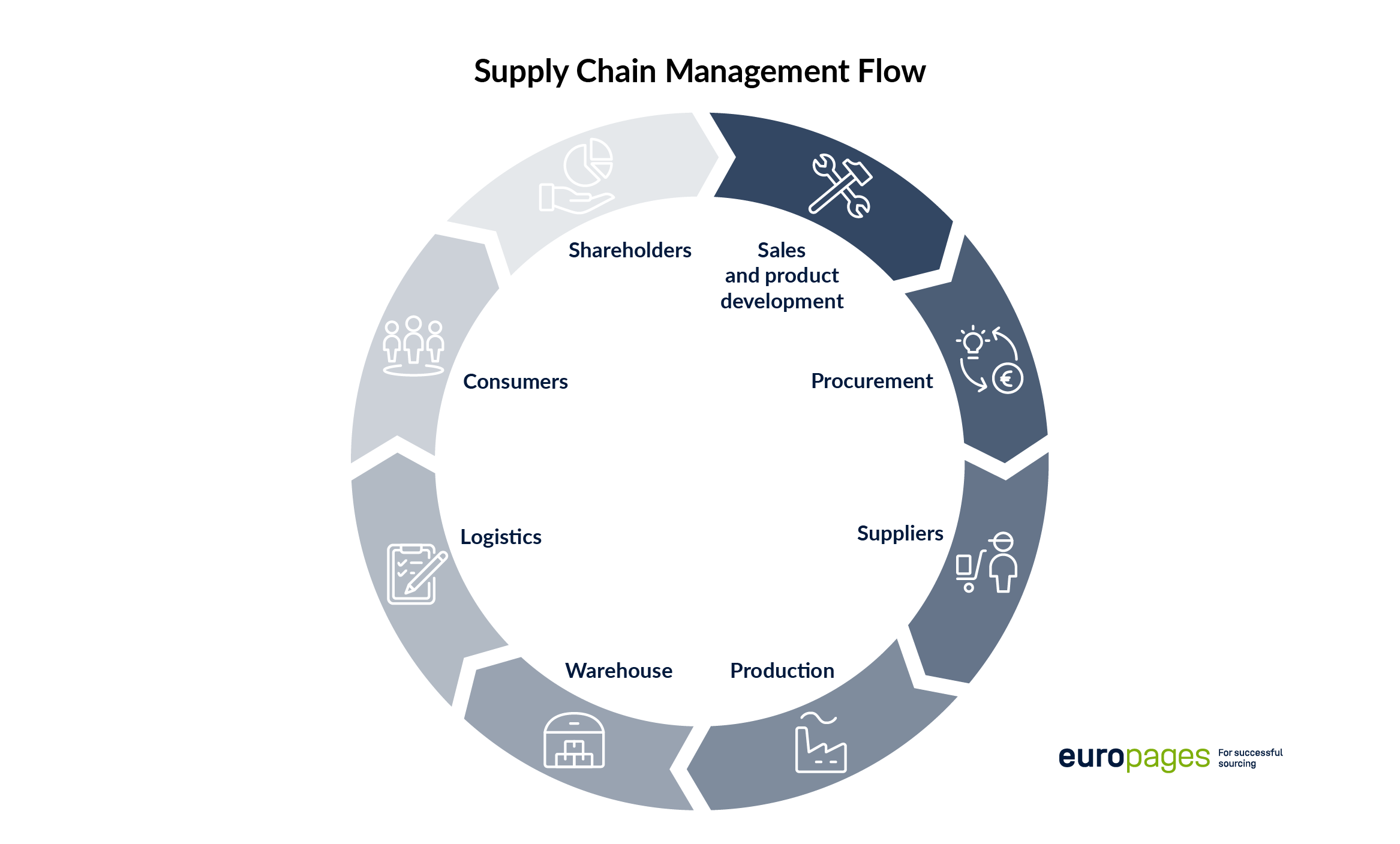

The supplier selection process depends above all on the strategies and objectives you are pursuing as a company: are you aiming for market leadership, do you want to establish yourself as a driver of innovation, or is it particularly important for you to be seen as a reliable partner capable of providing many services? When selecting suppliers, a fundamental distinction can be made between the following key figures:

- Technology indices

- Logistics indices

- Quality indices

- Purchasing indices

Is the technological equipment compatible?

How modern is the supplier? How much do they invest in research and development? These questions are particularly important in the selection process if your company wants to engage in technological progress. In addition, it is advisable to keep an eye on the supplier's technological achievements: how quickly can the supplier implement new technologies? Is an increase in personnel and/or resources necessary?

Can on-time delivery be ensured?

On-time delivery and reliable deadline management are essential when selecting a supplier. If production stops due to a shortage of parts, this will have fatal consequences for the company's reputation. Goods must not only be delivered on time, but also in the quantities ordered. There are many factors that can enable the supplier to anticipate these problems, including trained employees and efficient working methods. Compatibility of the company's and the supplier's software and systems also helps to ensure that deadlines are met: if the supplier uses the same systems as you, both parties benefit from a simplified ordering process.

Present your company on our platform!

The advantages:

- International audience and visibility

- Set-up in 5 minutes

- Numerous options and services through individual content

Is the quality satisfactory?

If the parts you use are not of high quality, the product produced will not be of high quality either. Ultimately, a company's reputation depends on it too. In procurement, the error rate of a product is calculated in ppm: ppm stands for parts per million. The lower the error rate, the more suitable the supplier. In the automotive industry in particular, suppliers are required to have a very low ppm rate, often around 20 ppm.

In the context of quality management, it is also necessary to ensure that the supplier has the appropriate certifications: ISO 9001 for the implementation of quality management and/or ISO 14001 for the implementation of environmental management.

Ultimately, quality also includes service and availability.

What (additional) services are included in the service? Is training or assistance with installation offered? Is the service department easily accessible and does it handle questions or complaints competently? A permanent contact person who gets to know your requirements within the framework of the partnership with the supplier would be ideal.

Price and other: what is important for the acquisition?

Price should not be the only factor in the selection process, but it should still be taken into account. After all, it will influence the price of the finished product and therefore its importance on the market. Always consider price and quality: a disproportionately cheap product may be of poor quality. A lower purchase price can often be achieved through long-term contracts with the supplier. Payment terms are also an interesting point, as they can make the price more or less advantageous. If you get a 30-day payment term, you can use the money for other purposes, whereas with cash on delivery, the payment will be due, as the name suggests, on delivery.

Finally, the transparency of the offer is very important. The buying company must be able to understand the supplier's offer and the composition of the final price. Hidden costs or minimum quantities have no place in a transparent offer.

Find the right supplier strategically

In order to find the perfect supplier, it will always be necessary to take into account the company's objectives. While some criteria can be assessed subjectively, others, such as reliability and punctuality of delivery of goods, are essential. On the other hand, although price should be taken into account, it should not be the only selection criterion. A study on supplier selection in Swiss companies by the Swiss Federal Institute of Technology Zurich found that quality is the top priority for companies when selecting suppliers. This is followed by procurement costs, service level and flexibility.

Overview of supplier selection criteria

What is a suitable supplier? The answer to this question can only be given according to the requirements of the company. Thus, the choice of a supplier is a strategic process by which the company can achieve a partnership based on trust and sustainability.

- Quality

- Error and failure rates

- Regulation of commercial flexibility

- Reliability of deliveries

- Permanent contact persons

- Transparency of the offer

- Price guarantees

- Assessment of creditworthiness

- Innovation potential

Choosing the perfect supplier:

- Determine which supplier selection criteria are decisive and which are less important.

- The supplier must fit your business strategies and objectives.

- The right supplier is always a subjective decision, which should result in a long-term, trust-based partnership.