How the chip shortage affects UK companies

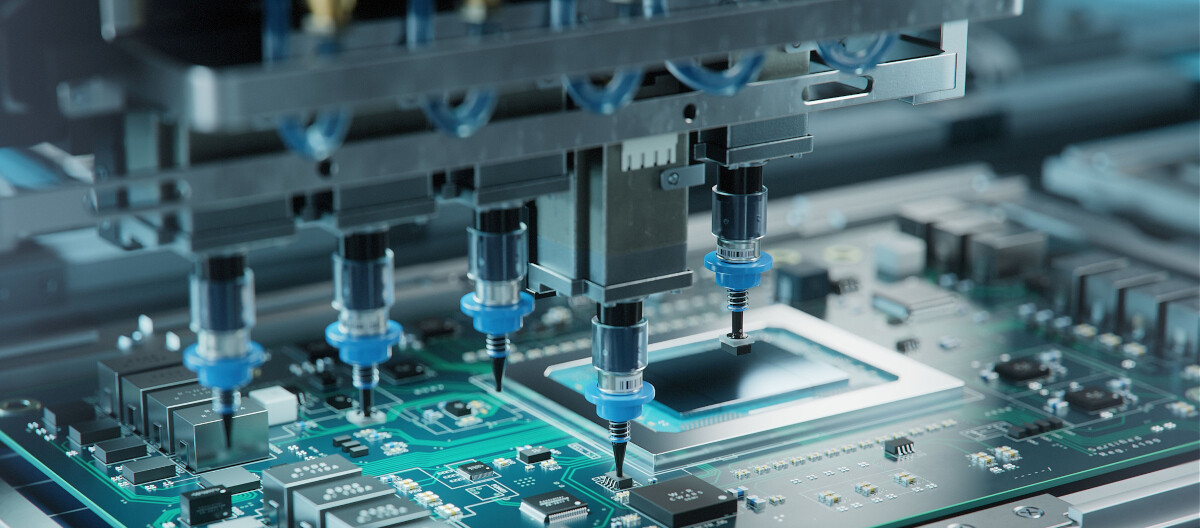

The current global chip shortage results from a mismatch between supply and demand: in today’s digital era, there’s a very high demand for electronic components. Almost every digital device contains semiconductors, the basic materials needed to make chips and integrated circuits. All devices which need to calculate or process information contain these chips: mobile phones, computers and even household items such as vacuum cleaners.

In the UK, the car industry has been particularly impacted by the chip shortage, with car production declining by -9.8% in 2022. With the industry increasingly transitioning to electric and autonomous vehicles, the demand for chips with greater computing power has compounded the issue. There’s some signs that this trend is starting to reverse, with big name companies such as Bosch investing in chip production for the automotive industry to avoid future supply chain issues. But is it too little, too late?

The chip industry: signs of recovery, but challenges remain

Like the COVID-19 pandemic which prompted it, the chip shortage is a global challenge. Geopolitical issues also play a part: the ongoing tensions between the US and China have resulted in US government constraints on sales of chips to China, with a subsequent knock-on effect on the rest of the world. A recent Deloitte report on the semiconductor industry notes that the market for generative AI chips is currently strong, but it remains unclear whether prices and volumes will increase or decline. So why can’t we just make more chips? The answer is that chip manufacturing is complex and expensive, requiring not just high-tech machinery, but also specialist facilities which need to run 24 hours a day. It’s estimated that building an entry-level chip factory costs around £12 billion. What’s more, given the current pace of technological development, these facilities will become obsolete in five years or less. In the short term, companies have to consider more immediate measures.

Hints and tips for companies: managing the chip shortage

Although the global situation may be beyond your control, there are still steps small- and medium-sized businesses can do to minimize the impact of the current chip shortage.

Here are a few suggestions:

- If possible, use older chip technologies as a temporary measure

- Focus on software updates rather than new hardware

- Look at your product range to see if any could be produced without scarce chip components

- Take advantage of AI to speed up the research and development process and to support risk assessment – this will increase the efficiency of the supply chain

- Remember that large purchasing volumes are nearly always an advantage in negotiating prices and ensuring security of supply

The UK semiconductor industry: a strategy for the future

While it’s impossible for a single country to onshore the entire process of semiconductor design and manufacturing, the UK is preparing to address the chip shortage through the government’s National Semiconductor Strategy, which sets out a vision for the next 20 years. Recognising that semiconductors are one of five critical technologies for the UK government, the report focuses on the UK’s strengths in intellectual property and design, compound semiconductors and research and development.

The National Semiconductor Strategy has three core objectives:

- Growing the domestic sector

- Mitigating the risk of supply chain disruptions

- Protecting national security

In March 2023, US company Vishay acquired the largest semiconductor plant in the UK, in Newport, Wales, confirming the UK’s importance for the industry. In the same month, the government announced that British semiconductor researchers and businesses would have enhanced access to research funding backed by both the UK government and Horizon Europe, with the UK joining the EU’s Chips Joint Undertaking. In February 2024, two Innovation and Knowledge Centres were created in Southampton and Bristol, which will each receive £11 million to help bring new chip technologies to market.

A UK plan for chips

Industry body techUK has responded to the government’s strategy with a UK Plan for Chips, highlighting the need for the UK to build on its existing strengths and future potential to ensure the success of its industry in a competitive global value chain. To achieve this, it has proposed a five-point plan:

- Retaining the UK’s position as a global leader on chip intellectual property and design, by modernizing R&D incentives

- Incentivising investment in advanced designs, new material and new fabrication plants.

- Partnering with global allies on supply and monitoring the UK’s access to chips

- Nurturing the skills needed for the chip industry by supporting talent attraction via the immigration system, shortage occupation lists and university talent matching, and identifying semiconductor centres of excellence across the UK

- Ensuring access to markets and private capital by addressing the scale-up gap and providing continued access to a diverse range of customers and markets.