- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machinery

Results for

Industrial machinery - Import export

REINASAN BV

Netherlands

With this animation, we try to give a brief and clear explanation of our system for the food industry in a playful way. More details on this and possibly other Reinasan systems can be found here on Europages, our website and on our YouTube channel. We'd love to hear from you! Feel free to send us a message via this platform. Have fun watching!

Request for a quote

REINASAN BV

Netherlands

Production processes often grind to a halt as pollution takes over. Daily cleaning is a necessary thing with relatively short effect. A momentary effect. To continue production processes, intensive and heavy alkaline chemical cleaners are used periodically to remove accumulated soiling. Reinasan has developed a system that ensures improved hygiene, less absenteeism, less waste, fewer process failures and it improves food safety, among other things. First, the 24/7 active protection agent is applied. Then one can clean or maintain daily with the pH neutral and environmentally friendly products. By measuring 'on the spot', you keep a grip on the cleaning and safety situation. We are also looking for distributors with their own B2B network. Let's become more sustainable together and leave the world cleaner behind than we found it!

Request for a quote

KASAG SWISS AG

Switzerland

Special equipment, production aid, pipeline construction, assembly In a dynamic market environment, new constructions, modifications, production expansions and the potential for process optimization not fully exploited, represent constant challenges, even in the food industry. The experts at KASAG support and accompany you in all your investment and maintenance projects in the food technology with design, engineering, manufacturing, pipeline construction and assembly. In addition, you will have access to KASAG’s knowhow in the areas of energy recovery (renewable energy) and pressure vessel construction. With KASAG as your partner, you can count on specialists on location.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond DSV Sideshooter provides reliable detection of foreign objects in upright tall packaging. The compact, hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes.

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

FLOTTWEG SE

Germany

Flottweg nozzle separators (2- and 3-phase nozzle separators) are used for the continuous separation of solids from liquids and ensure highly efficient clarification or separation. The product to be clarified or separated flows via a stationary inlet pipe into the inside of the bowl and is gently accelerated to operating speed by the distributor. Characteristics of our nozzle separators: — Energy-optimized and low-wear bowl design — High performance — Simple and fast maintenance — Designed for perfect hygiene The Flottweg nozzle separators are available in two basic designs: — Clarifier / 2-phase nozzle separator — Concentrator / 3-phase nozzle separator

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

BIZERBA SE & CO. KG

Germany

For the formation of pre-defined package units downstream of a Bizerba labeling system The fully automatic TU 100 unit maker consists of an electrically driven, two-part package removal station with an electro-pneumatic diverter arm. It makes units according to predefined criteria, optimizing the packing process and the control of sum labels for the packages. Up to 100 packages per minute are possible. The TU 100 can be optionally fitted with a roller conveyor or a belt conveyor. (optional)

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

300 LT LIQUID SPICE MIXER MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Our machine features a single-walled stainless steel boiler. Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 2 mm Liquid Spice Mixer - Mixer Gearbox: 80 RPM 0.75 KW Electrical components are SCHNIDER or DELTA brand. Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing.

Request for a quote

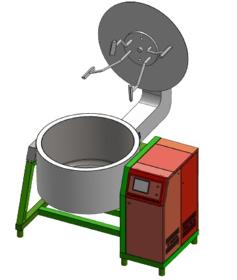

ET TAMBURU DONER TEKNIK

Turkey

COOKING BOILER MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Our machine features a double-walled stainless steel boiler. Maximum Safety Gas heating system Automatic mixing system Automatic opening and closing lid system Hydraulic tipping system Automatic recipe system Easy operation with digital touch screen Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: Front Dome: 4 mm Rear Dome: 4 mm Mixer Motor: 80 RPM 2.2 KW

Request for a quote

ET TAMBURU DONER TEKNIK

Turkey

ETDSK - 150 LT MACHINE TECHNICAL SPECIFICATIONS Chassis: Designed with a focus on strength, durability, and aesthetics. Chassis Material: Entire chassis is made of 304 CrNi material. Boiler: Our machine features a double-walled stainless steel boiler. Vacuum System Maximum Safety Automatic Recipe System Easy Operation with Digital Touch Screen Boiler Plates: The boiler plates are entirely made of 304 quality CrNi material. Boiler Body Plate Thickness: 4 mm Rear Dome Plate Thickness: 4 mm ETDSK Mixer Gearbox: 80 RPM 1.5 KW Ensures thorough blending of added spices. Ensures optimal binding of added proteins. Prepares the product for further processing.

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

RICE CAKE MACHINES (SYP Model) As this Shinyoung Mechanics is a company which specializes in production of the Rice Cake Popping Machines, we are keeping the No. 1 domestic sales through the 2007 SYP series and being recognized its excellence selling the product of over 1,500 units to 50 countries worldwide. Since our SYP Rice Cake Popping Machine is that design is compact and convenience is superior on the use and time, thickness, shape etc are possible to control easily, it is in wide use from store up to factory. As the 100% Grain Snack is that nutritious ingredient is excellent and consumer recognition is good, it is easy to commercialize. As of now a variety of products such as general snack (chocolate-coated, flavor-seasoned), cereal for meal substitution or diet, children snack etc are being developed and sold. Thank you

Request for a quote

SHINYOUNG MECHANICS CO.,LTD

South Korea

The rice cake popping machine of Shinyoung Mechanics is a device that can make grain snacks, chips, cakes, etc., out of 100% natural cereals. Gluten free products using rice or corn can be made, and breakfast cereal or children’s snacks can also be made with wheat, sorghum, barley, brown rice, buckwheat, etc. Also, using various food pellets, potato chips, beans, or sweet potatoes can be made into healthy snacks without going through the frying process. As you can see in the photo, you can make grain cake with rice or wheat, and you can produce cake or chip type product using various shapes and various raw materials. Users Large confectionery producer Medium and small sweets producer Snack manufacturer Rice cake maker Grain distributor or processor Large food manufacturer Medium and small food manufacturer Small local shops using local specialties or local mascot shapes For more information, please contact us !! Thank you Shinyoung Mechanics

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHINYOUNG MECHANICS CO.,LTD

South Korea

RICE CAKE MACHINE (SYP Model) As this Shinyoung Mechanics is a company which specializes in production of the Rice Cake Popping Machine, we are keeping the No. 1 domestic sales through the 2007 SYP series and being recognized its excellence selling the product of over 1,500 units to 50 countries worldwide. Since our SYP Rice Cake Popping Machine is that design is compact and convenience is superior on the use and time, thickness, shape etc are possible to control easily, it is in wide use from store up to factory. As the 100% Grain Snack is that nutritious ingredient is excellent and consumer recognition is good, it is easy to commercialize. As of now a variety of products such as general snack (chocolate-coated, flavor-seasoned), cereal for meal substitution or diet, children snack etc are being developed and sold. Thank you

Request for a quote

FORMEX MAQUINARIA

Spain

CLEANLY DOSES AND INJECTS FOOD MASSES OF DIFFERENT DENSITIES AND CHARACTERISTICS: viscous, liquid, soft, creamy, dense, sugary, etc. THE MIXTURE CAN HAVE SOLID PARTICLES INCORPORATED. For small and medium productions, although they can also be integrated into a working line or conveyor to achieve a higher degree of automation. IDEAL FOR DISPENSING PRODUCTS SUCH AS: muffins, plum-cakes, tartlets, custards, jams, sauces, fruit fillings, delicate fillings such as mousse, salad dressings, soups, Russian salad, creams with cereals, dairy products, etc. A WIDE RANGE OF ACCESSORIES AND DOSING OUTPUTS provide versatility when working with different products efficiently: mould conveyor, hose and hand gun, transfer pump, rotary cutting gun, injector nozzles, elevator, etc., elements that will make your work more precise.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vibratory batch sieving machines to remove contamination from small batches of products, improving product quality and reducing downtime. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Pneumatic sieving equipment to remove oversize contamination within blowing lines. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Bag tipping platform for hand fed raw ingredients from bags. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vacuum conveying sieve for air-tight sieving and conveying of fine and dusty materials in one operation to improve production capacity. For more details, please send us a message or click on the website link.

Request for a quote

RUSSELL FINEX LTD

United Kingdom

Vibratory sifters for high containment applications such as pharmaceutical powders to improve product quality and safeguard operators health and safety. For more details, please send us a message or click on the website link.

Request for a quote

INDUPLAST PLÁSTICOS DE INGENIERÍA

Spain

At Induplast we work with plastics for the food industry that have been approved by FDA regulations for contact with food products and we have engineering plastics with additives for metal detection that prevent contamination and guarantee traceability and compliance with migration limits. We also use high-performance machinery that allows us to obtain plastic moulds for food and food machinery, guaranteeing the best quality.

Request for a quote

PKO-SURA COMPANY

Russia

Cooling of confectionery and bakery products before packaging is one of the most long-run (up to 5 hours or more) processes in production. The conveyor belt with the length of more than 300 m is necessary to transport the products during this time. Сура СKБ spiral conveyor is the best option for a conveyor system for cooling products for a long time. Due to the spiral geometry of the belt arrangement in space, it is possible to provide a large length of the belt in a minimum volume that essentially saves production space. In addition, the product is transported on a spiral conveyor belt as softly as possible, without rolling from one lay to another like in multilayered systems.

Request for a quote

PKO-SURA COMPANY

Russia

It is designed for high-quality and uniform coating of various confectionery products with various types of glaze: chocolate fat sugar syrup, etc Due to the tank heating jacket and a mixing device, the glaze is heated to the operating temperature. The glaze is pumped into the glazing tank, and then the tank slide gates are opened and adjusted to obtain a straight, steady stream. The products to be glazed are placed on the feed conveyor and the conveyor is powered up. The products are transported on the large conveyor to the glazing area and then to the blowing area to remove excess glaze from the top. The bottom of the product is smoothed with the special rollers and then the products are transported to the cooling area. The glazing machine can be equipped with a decorator. Products can be glazed separately from the top, bottom or all sides. The machines for glazing with sugar syrup are manufactured considering some modifications necessary to operate the fast-hardening products.

Request for a quote

PKO-SURA COMPANY

Russia

Highly automated machines is designed for dosing of dough of various shapes and sizes without or with filling from different confectionery products on a baking pan by extrusion: -shortbread dough (hard or soft); -gingerbread dough; -dough for oatmeal cookies; -biscuit dough; -protein mass (souffle sweetmeat, pastille, marshmallow) The two-hopper mechanism of Сура СД and Сура СДУ depositors ensures the dosing of dough for double-color products or single-color filled products. All Сура С, Сура СД, Сура СДУ machines in standard version are equipped with mechanisms for rotation of draw plates and movement of the conveyor in the vertical plane. Сура СДУ universal depositor can be equipped with a diaphragm cutting unit where the diaphragms can be arranged both in single row and in staggered rows. Possibility to equip any Сура С, Сура СД, Сура СДУ machines additionally with a string cutting unit given that the frame of all machine s are equipped with the connection elements.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

Belted bucket elevator is very ideal for vertical conveying of bulk materials or products, which have particle size up to 50 mm

Request for a quoteResults for

Industrial machinery - Import exportNumber of results

94 ProductsCountries

Company type