- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat treatment

Results for

Heat treatment - Import export

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Our Heat Treating Suppliers are certified by Aeronautical and Automotive Industries. Annealing Normalizing Stress Relieving Quenching and Tempering Vacuum Hardening Homogenization Decarburization Nitriding Carburization Case Hardening and more

Request for a quote

EMSIL TECHTRANS SRL

Romania

Emsil Group is capable of manufacturing complex products based on our Customer's drawings and specifications. Over the years we have expanded our capacities and capabilities into manufacturing most if not all process steps. Today, these capabilities allow us to manufacture turnkey projects at our 3 production sites and also provide additional services through our extensive network of collaborators. The industries in which we are active are: vacuum, energy, oil & gas, naval, aerospace and metallurgy. Types of products we manufacture Glass coaters and packaging machines in the vacuum industry Baseplates and chassis for the oil & gas and energy industries Winches and crane components for the naval industry Pressure vessels from carbon steel and stainless steel PROJECT MANAGEMENT DESIGN & ENGINEERING CUTTING ASSEMBLING & WELDING PRESS BREAKS FOR BENDING ROLLING MACHINING HEAT TREATMENT SURFACE TREATMENT FINAL ASSEMBLY & AUTOMATION CUSTOM PACKAGING & DISPATCH

Request for a quote

WIB SA

Switzerland

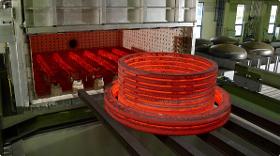

The 100 Cr6 steel rings manufactured by WIB are stabilized after hardening by annealing. As a result of this treatment, they can be used at temperatures of up to 150°C. They have a hardness of 60 to 64 HRC For applications operating at high temperatures or in order to reduce their sensitivity to shock loads, it is necessary to stabilize the rings at higher temperatures after hardening. It should be noted that such a stabilization will slightly reduce the hardness of the rings.

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

It is the general name of the placement aimed at improving the mechanical properties of heat treatment metals. A type of metallurgical process. Generally, it is done by annealing metals in a certain way, bringing their structure to the desired stage.

Request for a quote

FRIGORTEC GMBH

Germany

Using the DEBUGGER method (heat treatment) from FrigorTec, the DEBUGGER DB18 has proven its effectiveness in killing insects, larva, and eggs, for decades. This method increases the air temperature to a range between 45°C and 60°C, and keeps it there, so that pests die off without using chemical substances, thus preventing damage to buildings and their fittings. A power distributor is required depending on the size of the installation site or the number of devices, and we recommend using one or more SCRAMBLER SC 6000s to save energy. Fields of application > Specially developed for large spaces, e.g., mills, bakeries, the food-processing industry > Often used in spice and coffee processing, as well as in the tobacco industry, muesli manufacture, and small animal feed production > Combine several DEBUGGER DB18s in very large rooms and halls

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

CRC PROGETTI SRL

Italy

Heat treatment OPERATING TEMPERATURE: MAX 1200°C Standard power, size and shape or as indicated by the customer. Complete electrical BOXES with CONTROL and SAFETY systems (thermocouples). Stainless steel casing. Room insulation with technical material REFRACTORY and FIBROCERAMIC. Heating by resistive filament* SPIRAL. VIDEO: LINK

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 455 is a ½ DIN powerful controller designed to monitor, control and record a variety of heat treating processes. Used in new furnaces as well as for refurbishing or updating existing systems, it is ideal for nitriding, nitrocarburizing, carburizing, carbonitriding, hardening, tempering and vacuum furnaces. FEATURES • color touch-screen interface • built-in chart recorder function • calculates variables such as % carbon, dew point, or millivolts, and percent oxygen • stores up to 200 19-step recipes • direct drop-in replacement for Marathon Monitors’ CarbPro, DualPro, MultiPro, and Carb PC • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750, & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Protherm controllers are universal configurable programmers that monitor, control and record processes running in a single furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • Up to 32 PID control-loops to regulate parameters such as temperature, furnace pressure, atmosphere parameters (e.g.: carbon potential, nitriding potential and oxygen potential) • Real-time monitoring of jobs at all stages • Process parameters configured with alarm limits • Online diffusion calculation to control the process using required target values (e.g.: case depth, surface carbon content) • Up to 999 treatments/templates can be created and modified • Integration with SCADA systems • For all types of processes: nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • For compliance with CQI-9, AMS 2750 &..

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

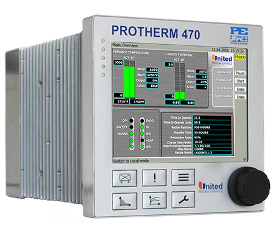

The Protherm 470 controller is designed to monitor, control, record and archive heat treatment processes running in a furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • ½ DIN multi-loop embedded programmer with a color display and turn-and-push knob navigation • Up to 32 programmable PIDs included • built-in calculators for real-time carbon and/or nitrogen diffusion, and hardness profile • mathematical model for calculating atmospheric parameters • integrated web server for browser-based remote access • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750 & AMS 2759/10-12

Request for a quote

KANAT CELIK

Turkey

DIN: 25CRMO4 / 42CRMO4 / 41CR4 / 34CRNIMO6 SAE: 4140 / 5140 / 4340 / 4130

Request for a quote

FCM STEEL INDUSTRY CO.

Turkey

O HEAT TREATMENT BASKET CASTİNGS O HEAT TREATMENT FİXTURE AND GRİDS O FURNACE GRATE DESİGN O IMPELLER CASTİNGS O DİFFUSOR CASTİNGS

Request for a quote

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Dimensions up to 600x600x900 mm, weight up to 800 kg. LPC (vacuum cementation) option. Hardening, heating in a gas environment and isothermal cooling.

Request for a quote

PLASTIC PALLETS UK / ASSOCIATED PALLETS LTD

United Kingdom

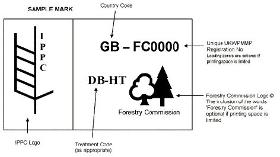

ISPM15 is an international standard for phytosanitary measures which is being progressively implemented throughout the world. Already some 28 countries have adopted the standard; a further 21 are in the progress of doing so and about another hundred countries have signalled their intension to bring the requirement to their national regulations. Countries which have signed up to ispm-15 are entitled to refuse entry at their frontiers to goods on wooden pallets, crates, spools or any other wood packaging unless it has been treated, marked and certified in accordance with their regulations. Associated Pallets Ltd has been providing a heat treatment which meets the demands of ISPM-15 and since the introduction of the plant some four years ago, has become experienced in all needs of the wood packaging producer and user.

Request for a quote

ERATEC

France

Tissue drying Lamination Ironing Heat treatment rollers

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

At our company, we offer comprehensive heat treatment services for both steel and aluminum products. Our team consists of expert associates who are leaders in their respective fields, ensuring top-notch quality and precision in every project. Additionally, we provide valuable consultation to help you determine the best available options or optimize processes to achieve your desired results efficiently.

Request for a quote

SIA BROCENI PELLETS

Latvia

Dimensions: 1200 x 1000 x 145 mm Standards: According to your own specification, IPPC ISPM-15 heat treatment, kiln drying, certified nails Material: Soft and hard woods (e.g. pine, spruce, poplar, alder, beech etc.) Additional info: 4-way entry or 2-way if produced with stringers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BORNEMANN GMBH

Germany

Matrices for punch units according to your drawings or data. Heat treatment is carried out in accordance with the purpose. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

ISTANBUL DOKUM SANAYI VE TICARET A.S..

Turkey

Istanbul Dokum is an organization, has flexible production methods enable to cast, iron, nodular iron, steel, stainless steel, duplex, super duplex and bronze in sand molding system in a single foundry. Our foundry, as different from the hundreds of foundries across Turkey and Europe, complex is equipped to supply castings to customers. In our induction furnaces, your orders are casted carefully with our qualified personnel. Casting cleaning is carried out by a separate team within our structure and some parts are subjected to heat treatment in accordance with special demands. We apply heat treatment in order to achieve better mechanical values depending on the end use areas. Sandblasting is done in our 2500x2500x3500(h)mm inner dimensioned sandblasting machine with a single piece capacity of 10 tons.

Request for a quote

ERATEC

France

Preheating of forging tools Preheating of tubes before welding Preheating before thermal spraying Preheating of moulds

Request for a quote

MOH D.O.O

Slovenia

materials Titanium & stainless steel, nickel alloys, aluminium, steel tools surface and heat treatment, sandblasting, NDT testing

Request for a quote

WORLDWIDE MACHINING SPARE PARTS

Turkey

420 quality stainless steel can be hardened by many heat treatments like high carbon steel. It contains at least 12% chromium (Cr) and this alloy is sufficient for corrosion resistance. It has good softness in annealed condition, but it has the ability to get 50 Rockwell hardness by heat treatment. For best corrosion resistance it must be hardened and gets it surface cleaned or polished.

Request for a quote

ESSELATE AB

Sweden

Dimensions: 1200 x 1000 x 145 mm Standards: According to your own specification, IPPC ISPM-15 heat treatment, kiln drying, certified nails Material: Soft and hard woods (e.g. pine, spruce, poplar, alder, beech etc.)

WIB SA

Switzerland

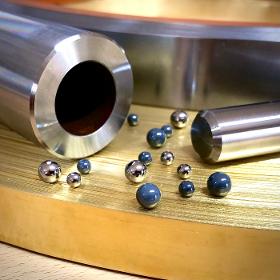

We offer a wide range of material depending on the needs of the application. When working with our application engineers, we will select the material type (and heat treatment method) to ensure the bearings meet the requirements of the application. This includes factors such as high wear resistance, heavy shock loads, extreme corrosion, as well as dimensional stability.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

These Roller Followers are lubricated with CLube, a thermosetting solidtype lubricant which fills the inner space of the bearing. CLube is lubricant made of a lot of lubrication oil and fine particles of superhigh molecular polyolefin that are solidified by heat treatment. As the bearing rotates, the lubricating oil oozes out onto the raceway surface in proper quantities, maintaining the lubrication performance for a long period of time.

Request for a quote

H.B.A STEENS ILMA TRADING BV

Netherlands

1/2 Branded markings of the European Pallet Association e.V. 3 IPPC branded marking in accordance with the national plant protection rules (mandatory since 01/01/2010 for EPAL pallets) 4 Country code 5 Registration number of the responsible Plant Protection Authority 6 Method of treatment (heat treatment) 7 EPAL control staple (mandatory) 8 Repair nail (only present if the pallet is a repaired EPAL pallet) 9 Licence number - Year - Month

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO's Extended Life Specification Machined Type Needle Roller Bearings are treated with a newly developed special heat treatment that enhances the bearing's surface hardness and toughness, and suppresses the generation and growth of damage on the surface. Significant life extension can be achieved under high load or under the condition of lubrication contaminated with foreign substances. In a life comparison test, IKO's special heat treated Extended Life Series products lasted 5 times longer than standard heattreated products.

Request for a quote

EC PLAZA

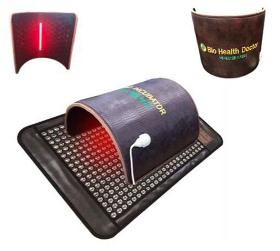

South Korea

The effect of carbon film + far infrared ray + near infrared ray + illite ceramics! Far-infrared rays remove impurities and dead skin cells from the skin surface, and near-infrared rays penetrate to the dermis and burn fat. By attaching a rare mineral Illite, the effect of far-infrared rays is more than doubled. 1. Made of airplane wing material, it is lightweight. 2. It is safe from fire by using carbon fiber. 3. A rare mineral ilite, produced only in Yeongdong-gun, Chungbuk, is attached. 4. Once purchased, it can be used semi-permanently. · Size : (width) 58cm / (length) 68cm / (height) 33cm · Rated Voltage : 220V 60Hz · Power Consumption: 440W · Material : external finishing(leather), reflection film, thermostat finishing, metal structure, radiant heat(pyrogen) film, carbon coating fiber, ceramic + silicone adhesive

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quoteResults for

Heat treatment - Import exportNumber of results

158 ProductsCountries

- Germany (46)

- Turkey (16)

- Ukraine (14)

- United Kingdom (11)

- China (8)

- Italy (7)

- France (5)

- Netherlands (5)

- Spain (5)

- United States (5)

- Belgium (4)

- Bulgaria (4)

- Czech Rep. (4)

- Russia (4)

- Slovenia (4)

- Austria (2)

- Lithuania (2)

- Romania (2)

- Switzerland (2)

- United Arab Emirates (2)

- Belarus (1)

- Latvia (1)

- Luxembourg (1)

- Portugal (1)

- South Korea (1)

- Sweden (1)

Company type

Category

- Heat treatment furnaces (17)

- Heat treatment of steels and metals (12)

- Bread, factory-baked (6)

- Prefabricated houses (6)

- Bearings - ball, needle and roller (4)

- Casting, steel (4)

- Confectionary (4)

- Infrared tubes (4)

- Pallets (4)

- Steels and metals - machining (4)

- Cereals and grains (3)

- Food packaging (3)

- Steel & Metals (3)

- Turning - steels and metals (3)

- Wire mesh, welded (3)

- Agricultural machines and accessories (2)

- Bearings, ball (2)

- Beverages - concentrates and powders (2)

- Brazing - equipment and supplies (2)

- Burners, industrial (2)