- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stators

Results for

Stators - Import export

BVS ELECTRONICS GMBH

Germany

Bosch Rexroth/Indramat motors The following options are available for motors from the ANAX, DIAX, ECODRIVE, INDRADRIVE and SERVODYN product ranges manufactured by Bosch Rexroth/Indramat Purchase a reconditioned replacement part or new part Replace a reconditioned replacement part or new part Purchase product overhaul repair or cleaning & inspection services We will be happy to supply an onsite service incl. support over the phone, upon request. Our extensive replacement parts warehouse with more than 100,000 instantly accessible modules provides our customers with a fast supply of replacement parts ensuring the costs of machine downtimes are kept to a minimum. We are proud to be the only company worldwide from the control and drive industry to bear the status of "Bosch Rexroth Service Point". We are therefore able to provide you with a warranty of up to 24 months on the services specified above for motors manufactured by Bosch Rexroth/Indramat.

Request for a quote

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Robust and durable As a naturally renewable raw material, wood is not only one of our favourite building materials, it can also be disposed of and recycled with comparative ease. For old wood recycling, tables, kitchens, damaged railway sleepers or chipboard are recycled using singleshaft shredders. In these machines, our cutting crowns and knife holders in a very wide variety of sizes and versions have been used for many years and have proven themselves in practice day after day.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL high-performance dispersing machines work according to the rotor-stator principle with high shear gradients. The extreme fine distribution of solids (suspensions) and liquids (emulsions) in presented liquid media is achieved by the perfectly coordinated interaction of various comminution processes. The high-precision dispersion tools are individually adapted to the respective task. Robust rotor-stator tools with a narrow radial gap ensure high shear gradients. A strong dispersing effect is achieved by impact and high-frequency pressure-relief processes. Solid particles and/or droplets are reliably comminuted and homogeneously distributed. Different rotor-stator-pairs allow the adaptation to the corresponding application. No rotating vessel contents - no formation of droplets and no air ingress. No free-running shaft and no free-running dispersing tools. Batch dispersion directly in the vessel.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL inline dispersing machines work according to the rotor-stator system. The dispersing machine is suitable for the production of suspensions, solutions and emulsions in the chemical, food, pharmaceutical and cosmetic industries. Due to the close radial gap between rotor and stator and the high circumferential speed of the rotating rotor, very large shear gradients are generated. The product enters the shear zone through the slots between the rotor teeth and leaves it again via the stator slots. Due to the multi-tooth configuration of rotor and stator, additional mechanical forces act on the product to be dispersed. The product is guided through a rotor-stator system. The liquid is highly accelerated by the inner rotor ring, is completely decelerated at the stator ring and then accelerated again to maximum speed via the next rotor ring. In this way, solid particles and/or droplets are effectively comminuted and homogeneously distributed.

Request for a quote

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

The YSTRAL jet stream mixer fulfils all requirements for a complete and homogeneous mixing of the contents of a vessel. Effective micro- and macro-mixing of the entire contents of the vessel without the introduction of air. Complete mass transfer across all vessel levels due to vertical mixing. Up to 90% of the energy used is converted into vertical flow - no rotating vessel contents. Even heavy sediments are suspended by directed streams. Rotating parts are protected against unintentional intervention. With open tanks no tank fixing is necessary. A fast rotating rotor surrounded by a stator generates a downward directed guide jet which directs the liquid flow directly to the bottom of the container. At the bottom of the container, the stream splits and creates an upward flow on the outer wall. At the surface, the liquid flow is redirected towards the bottom of the tank.

Request for a quote

STRONG MAGNETS GMBH

Germany

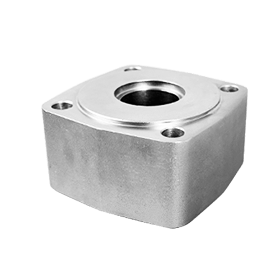

The stator is assembled by many pieces of all kinds of magnets and steel parts. We can provide customers customized stators and various of other magnetic assemblies.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

In rotary encoders with integral bearing and stator coupling, the graduated disk of the encoder is connected directly to the shaft to be measured. The scanning unit is guided on the shaft via ball bearings, supported by the stator coupling. During angular acceleration of the shaft, the stator coupling must absorb only that torque resulting from friction in the bearing, thereby minimizing both static and dynamic measuring error. Moreover, the coupling mounted on the stator compensates axial motion of the measured shaft. Other benefits of the stator coupling are: Simple mounting Short overall length High natural frequency of coupling Hollow-through shaft possible

Request for a quote

KUK COILS SLOVAKIA S.R.O.

Slovakia

KUK Group is your one-stop EMS service provider, as we offer the entire range from coil production to the assembly of a complete motor. High flexibility and fast turnaround times are the biggest advantages for the customer. Starting with coil manufacturing up to the delivery of a complete assembly, KUK offers a high degree of in-house performance. This is especially true with regard to the in-house automation department, which ensures tailor-made automation along the entire production process. "KUK's process competence thus extends from support in the design phase, to procuring or creating components, winding coils, assembling and delivery," explains CEO Manuel Inauen. -Assembly of winding goods to stators or complete motors -Individual testing instructions related to the product or process -Worldwide sourcing via subsidiaries

Request for a quote

POLITUBES

Italy

Nomex-Kapton -Nomex (NKN) tubes are stator slot liner insulators produced with a low thickness of only 0,16 mm without overlaps. This means an improved thermal management inside the stator slot, less overheating inside, higher torque and motor efficiency, more space for copper hairpins & I-Pins, improved dielectric strength. Reducing the thickness of slot insulator and improving dielectric & thermal insulation is a key stone to improve motor efficiency and performance in terms of: 1. Improving thermal conductivity and reducing thermal resistance 2. Reducing the temperature of the copper hairpin hotspot 3. By reducing the insulator volume because of a reduced thickness and lack of overlaps; this means that the amount of copper inside the slot can be increased, improving motor performance 4. Reducing phase resistance Nomex and Kapton are DuPont registered trademarks

Request for a quote

EUROTOOLS, S.R.O.

Slovakia

245,25x233x50 mm Stator knife for Eldan SCH middle

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

Stator packs and die-cast rotors (three-phase) available in IEC fame size 56 – 355, 2-, 4-, 6- and 8-poles . The standard core lengths are available in frame size 56 – 180 from existing stocks .

Request for a quoteResults for

Stators - Import exportNumber of results

15 ProductsCountries

Category

- Mechanical engineering - custom work (2)

- Steels and metals - forming and cutting (2)

- Automation - systems and equipment (1)

- Electrical & Electronic Components (1)

- Fastening devices - machines for production (1)

- Generating units (1)

- Magnets (1)

- Measurement - Equipment & Instruments (1)

- Milling - steels and metals (1)

- Steel (1)

- Substations, low-voltage (1)

- Tyres (1)