- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat exchangers

Results for

Heat exchangers - Import export

KASAG SWISS AG

Switzerland

Waste water treatment plants and surface waters have enormous energy potential. A sewage treatment plant, for example with 90 million litres of wastewater daily, reducing the wastewater temperature by using heat exchanger by around 1°C, generates a power of about 4.3 MW. The comparative potential for energy recovery from the surface water is even higher. Environmental aspect Induced by humans, water temperatures of the surface and streams have steadily increased, not least owing to the inflows from sewage water treatment. This has serious consequences on the flora and fauna. If heat is extracted from purified water in the sewage treatment plant or from surface waters and from streams, and water temperature is thereby reduced, this will have a positive effect on the entire ecological system. With KASAG heat exchanger systems, on the one hand, the energy requirement of the sewage treatment plant can be covered and, on the other, buildings in near vicinity can be heated or cooled.

Request for a quote

KASAG SWISS AG

Switzerland

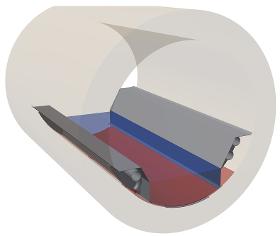

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote

KASAG SWISS AG

Switzerland

The use of energy potential at the place of its origin is optimal. Ensuring the heat transfer in the heat exchanger is thereby a vital criterion and requires customized solutions. The torrent of sewage flow in buildings is collected in a containment volume for generating energy using heat exchanger for heating and cooling. No retention volume is necessary for continuous outflows and process heating. This can be applied, for instance, in apartment buildings, residential buildings, communal buildings, hotels, thermal baths, swimming pools as well as in different energy-intensive industries, such as in foodstuffs, chemicals and pharmaceuticals.

Request for a quote

KASAG SWISS AG

Switzerland

The wastewater in the sewers is an ideal source of energy when combined with heat pumps and cooling machines, for heating and cooling of buildings. Per our experience, the minimal requirements for such a plant include: a wastewater flow of approx.. 10 l/s a wastewater temperature level of about 10°C a power requirement from 100kW (for heating and cooling from ca. 50kW). During the course of conveying wastewater to the sewage treatment plant, there are many possibilities for exploiting thermal energy. Wastewater can also be used many times over consecutively as energy source. Despite new inflows, or the confluence into larger canals, but also through heat influx from cooling systems, the change in temperature of the wastewater is mostly marginal. Innovative cities have ready energy guidelines (energy plans), based on which you can orient yourself to find out whether there is a suitable wastewater canal in your near vicinity (maximally approx. at a distance of 200 m).

Request for a quote

KASAG SWISS AG

Switzerland

Concepts, heat exchanger for energy recovery Energy dissipation and global warming cause damage to the nature and to the environment and thereby challenge our future. You can do a lot to prevent it. For instance, with innovative concepts and heat exchanger solutions for energy recovery so that water, wastewater, process fluids and exhaust vapours at the source in the building, in the industry, transported in the canalisation to the sewage treatment plan and even in the surface waters can be rendered useful thermally through heat transfer. Apart from the ecological aspects, investments in the realm of renewable energies are economically consequential. With KASAG as your partner for planning, design, engineering, and the construction of heat exchanger plants for energy recovery from waste heat, you are acting in favour of sustainability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVA WERKE AG - NOVA SWISS

Switzerland

The heat exchangers in our high-pressure series are especially designed for extremely high-pressure ratings of up to 20,000 PSI/1,380 bar and are manufactured in accordance with customer-specific requirements and wishes. The production of high-pressure heat exchangers is ASME or PED compliant. Compliance with special approvals and directives can be arranged on request. The heat exchangers of the Nova Swiss high-pressure series thus offer our demanding customers the option to cool or heat fluids and gases (including hydrogen) without having to reduce the operating pressures.

Request for a quote

BÜCHI AG

Switzerland

Heat exchangers are mainly used in vacuum distillation systems for cooling and condensation in the absorption and rectification processes in chemical plants. Glass heat exchangers enable visual process control during scale-up and production and processing of multiple (acidic) chemical substances. We offer glass spiral type and shell & tube type heat exchangers. These are often operated in combination with a secondary condenser for additional vapor condensation. The glass spiral heat exchangers can be operated in parallel to form large heat exchange areas for higher condensation performances and larger reactors systems in pilot plants. They feature easy cleaning and operation of cooling media at up to 3 bar pressure.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix specializes in demanding cooling and heat exchanger tasks such as cooling and heating of viscous or decomposition-sensitive media / plastic melts. The Promix P1 heat exchanger is the unique combination of a very efficient static mixer and a powerful cooler. The novel patented technology opens up completely new process engineering possibilities in the cooling and heating of plastic melts and other viscous fluids. The simultaneous mixing and cooling processes in the P1 allow for very efficient cooling and heating without the formation of deposits or the risk of product decomposition. Advantages Promix P1 heat exchanger Very efficient cooling of polymer melts close to the solidification point Precise temperature control and uniform temperature distribution at the outlet Very robust construction Extremely gentle cooling and heating of residence time critical fluids Unique self-cleaning behavior Reliably scalable from laboratory test to production scale Test options

Request for a quote

KASAG SWISS AG

Switzerland

KASAG is a qualified sub-supplier for nuclear technology, for which we have an ASME-manufacturer permit. We process stainless steel and special materials for you corresponding to nuclear standards with regard to material traceability and quality documents. With KASAG as partner, safety comes first. Cryo technology is used for generating extremely low temperatures of under -150°C. Special physical effects can be used in the process for liquefaction and separation of gases. Manufacturing pressure containers for cryogenic temperature applications requires specific welding processes and certified KASAG welding specialists. For even for lowest temperatures KASAG is your first choice.

Request for a quoteResults for

Heat exchangers - Import exportNumber of results

10 ProductsCompany type