- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- temperature chamber

Results for

Temperature chamber - Import export

KLÖPPER-THERM GMBH & CO. KG

Germany

Complete ready to install heating mats, with or without spare heating cable, consisting of heating cable, cold lead and temperature sensors. Concrete floor heatings from Klöpper Therm are the optimum protection against dangers from black ice in cold stores. Concrete brings heat from outside into the cooling chamber. Thereby the temperature of the concrete along the heat flow falls to the temperature of the cooling chamber. The moisture stored in the warmer air condenses on the cold concrete surface through which black ice can form. Dangers through the exchange of warmer and colder air arise particularly in the area of locks. When, through repeated opening of the doors, condensation from the walls and ceilings falls on the floor and black ice forms, it can lead to accidents. In consequence of the effects of permanent cold, doors can freeze solid at the seals and be severely damaged.

Request for a quote

FDM - ENVIRONMENT MAKERS

Italy

Temperature from -25°C up to +70°C Configuration Volumes from 25 up to 2300 liters stillFACE Stability test performing controller revoFACE Dynamic performing programmer Shelves Included and variable in quantity according to the model Ventilation Forced ventilation fan Alarms High/Low temperature and humidity Electric Power 220-240V ~ /50 Hz different power available 100% Customizable solution

Request for a quote

PEEKCHINA CO., LTD.

China

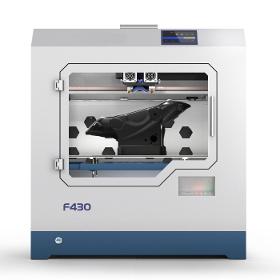

THE SYNERGY OF LARGE BUILD VOLUME AND HIGH-TEMPERATURE THERMAL DESIGN. High-temperature chamber for printing large functional parts with material PEEK Polymer without warpage & delamination.

Request for a quote

PEEKCHINA CO., LTD.

China

THE SYNERGY OF LARGE BUILD VOLUME AND HIGH-TEMPERATURE THERMAL DESIGN. High-temperature chamber for printing large functional parts with material PEEK Polymer without warpage & delamination.

Request for a quote

PEEKCHINA CO., LTD.

China

THE SYNERGY OF LARGE BUILD VOLUME AND HIGH-TEMPERATURE THERMAL DESIGN. High-temperature chamber for printing large functional parts with material PEEK Polymer without warpage & delamination. Large Scale. High Temperature. Industrial Production.

Request for a quote

PEEKCHINA CO., LTD.

China

THE SYNERGY OF LARGE BUILD VOLUME AND HIGH-TEMPERATURE THERMAL DESIGN. High-temperature chamber for printing large functional parts with material PEEK Polymer without warpage & delamination. Large Scale. High Temperature. Industrial Production.

Request for a quote

PEEKCHINA CO., LTD.

China

THE SYNERGY OF LARGE BUILD VOLUME AND HIGH-TEMPERATURE THERMAL DESIGN. High-temperature chamber for printing large functional parts with material PEEK Polymer without warpage & delamination. Large Scale. High Temperature. Industrial Production.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The SEPAP MHE is designed to perform accelerated photoaging of polymers with the aim of understanding the aging mechanisms of polymers exposed outdoors and examining the chemical evolution at a molecular level. Using a mercury vapor lamp, the SEPAP MHE is able to replicate and accelerate the chemical mechanisms responsible for the gradual loss in properties of polymers during their lifetime. The SEPAP MHE is capable of operating at irradiance levels between 90 W/m² and 300 W/m² (290 - 420 nm). Mercury vapor lamp (1000 W) 1040 cm² specimen rack capacity Irradiance range 90 - 300 W/m² (290 nm - 420 nm) Precise control of irradiance, Black Standard Temperature (BST) and chamber temperature Radio-controlled on-rack light and BST monitor XENOSENSIV Chamber temperature range up to 70 °C BST range up to 100 °C Full color multi-lingual user interface Relative humidity control using ultrasonic humidifiers (SEPAP MHE+) Relative humidity range 10 - 95% (SEPAP MHE+) Specimen spray with 60 liter integrated water reservoir (SEPAP MHE+)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Xenotest Alpha+ is a compact stand-alone rotating rack xenon instrument with 1320cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Alpha+ complies with the vast majority of industry standards setting the benchmark in narrow tolerance testing. Due to its highly reliable performance, it’s often chosen by R&D departments or commercial Service Test Houses. 1x 2200 W air-cooled Xenon Lamp 1320 cm 2 exposure area High-irradiance testing up to 180 W/m 2 (3 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window glass On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C), or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Specimen holder carousel for 11 specimen holders Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal BST Black Standard Thermometer XenoCal WST White Standard Thermometer XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor Turning mode programmable

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ is a premium stand-alone rotating rack xenon instrument with 4000cm 2 exposure area. It comes serially with a complete set of parameter controls. Irradiance and temperature are measured and controlled directly on the sample level using on-rack XENOSENSIV sensor technology. Beta+ complies with the vast majority of industry standards. Due to its large test chamber and highly reliable performance, it’s ideal for larger capacities or sample sizes. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area High-irradiance testing up to 120 W/m 2 (2 Sun) Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test methods Multilingual User Interface Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window On-rack XENOSENSIV 300-400 nm for measuring and controlling irradiance (in W/m 2) and BST (C°) on sample level Selectable Temperature control either by Chamber Temperature (max. 70 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 130 °C) Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Outer cylinder made of Special UV glass Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Thermoprinter XenoCal WST White Standard Thermometer XenoCal BST Black Standard Thermometer Rack spray system XenoCal BB 300-400 Irradiance Sensor XenoCal WB 300-800 Irradiance Sensor XenoCal NB 340 Irradiance Sensor

AMTEC TRADING GMBH

Austria

Moringa, also called the "miracle tree", is known for its nutrient-rich natural quality and contains more than 90 nutrients, vitamins, proteins and more. The Moringa leaves in our tea are harvested by hand, selected and freed from dust in a water bath. Then they are very gently dried in low-temperature drying chambers powered by solar energy. It is precisely this process that makes our tea so tasty and unique. -Grated Moringa leaves refined with ginger, liquorice and cardamom. -Gently processed, pure and natural -100% vegan moringa leaves from wild growth -The powerhouse Moringa has a high bioavailability and can be completely absorbed by the body -Original Ayurveda quality from the tropical Himalayan region

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The 220 is a large capacity lightfastness tester dedicated for textile testing. It comes with premium on-rack light and temperature sensor and non-aging optical filter technology. With the ability to test 38 samples, the 220 provides nearly twice as much capacity in the same footprint compared to 150S+. The combination of its large test chamber and the efficient use of power and water make it today’s most economic air-cooled instrument available. It complies to standards ISO 105 B02, AATCC TM16 (option 3), and Marks & Spencer C9, C9A. 1x 2200 W air-cooled Xenon Lamp 2310 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Message Storage for 10 user-defined tests Multilingual User Interface Non-aging filter systems for ISO 105-B02 and AATCC TM16 On-rack XENOSENSIV® for measuring and controlling irradiance (in W/m²) and Black Standard Temperature on sample level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 100 °C) simultaneously Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system with integrated 60l water reservoir for humidity control (automatic refill) Sample rack suiting 19 sample holders with capacity for 38 standard textile samples Pre-programmed standards ISO 105 B02 and AATCC TM16-2004 (Option 3) Switch-off by radiant exposure, light exposure or total operating time UV-protected test chamber window Advanced Auto Start functions Internal memory chip for storing instrument data Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) XenoCal BB 300-400 XenoCal BB 300-400 BST XenoCal BST

WIWOX GMBH SURFACE SYSTEMS

Germany

WIWOX® VIVERK are single and multi-stage spray chamber cleaning systems for aqueous cleaning, pretreatment and degreasing of tools and parts. Loading takes place via an extendable platform, which can be loaded at an ergonomic working height. The workpieces are mechanically cleaned by means of pump pressure in the spray chamber process. The temperature-controlled washing liquid is sprayed onto the workpiece via a spray frame.The washing plant is operated via a side switch box with electrical control. Before the washing process, the loading basket is loaded and driven into the rinsing chamber via a roller conveyor. The door is closed manually (optionally also automatically). The machine reaches an operating temperature of 40°C within just a few minutes. After a further 30 minutes, the maximum washing temperature of 70°C is reached. The motor-driven spraying gyro completely revolves around the parts to be washed.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

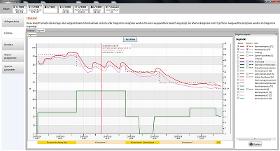

Creating highquality products in the food industry means balancing the desire for flexibility in the production of goods with absolute process reliability. This requires constant, seamless monitoring of all processes, as well as careful documentation of every intervention in the program flow. The FOOD.CON 2 adapts to your requirements. Equipped with a 12" touch screen made of special protective glass, the control is intuitive to operate and the selfdiagnosis function through fieldbus communication with all important components of the system ensures minimum downtimes and maximum system availability. Program optimizations can be carried out via remote maintenance via external access or directly via smartphone. During operation, the FOOD.CON 2 enables the precise monitoring of all important parameters in the system chamber temperature, humidity, core temperatures and much more are permanently recorded and made available as graphic evaluation for quality control.

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

High temperature combustion in gas flares is required when specific combustion parameters must be adhered to (TA Luft, governmental or local regulations) for reasons pertaining to the environment. One such parameter includes, but is not limited to, the emission of carbon dioxide (CO2) or nitrogen oxide (NOX). With special burner technology and a suitable combustion chamber suitable for temperatures > 1000 C, the ennox high temperature flare provides for and controls the correct combustion temperature. Our flares are designed to satisfy even the most demanding applications. At the heart of the NOXtreme flare control is the fully automatic control from the NOXmatic unit, which, if required can be extended to meet the actual project demands. The temperature control of the combustion process can be achieved either with a manual or automatic combustion air regulator.

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST CPS+ is the small entry model. CPS+ is the most widely used benchtop xenon instrument in the world. Its compact design, easy handling and proven reliability make it the ideal quality control and R&D screening device for a variety of industries, such as plastics, packaging, pharmaceuticals, cosmetics, and many more. 1x 1500 W air-cooled Xenon Lamps 560 cm 2 exposure area Measurement and control of Irradiance in the wavelength range 300-800 nm / Lux; or 300-400 nm / 340 nm Measurement and control of Black Standard Temperature (BST) Display of Chamber Temperature Display of Test Values and Diagnostic Messages Parameter Check Two pre-programmed test methods Storage for 6 user-defined test methods Multilingual User Interface Benchtop design 90 x 35 x 35 cm Static, horizontal exposure area for flat or 3D specimen Fan-controlled BST from 45-100 °C (without chiller unit SunCool) Non-aging reflector and filter system, consistent of selectively reflecting mirrors and a coated quartz Switch-off choices Radiant Exposure or Test Time Base Filter as carrier for additional optical filters Data output via serial interface RS232 Internally integrated Memory Card for Software Updates Light Monitor 300-400nm Light Monitor 300-800nm Humidity Sensor for measuring relative humidity during testing

Do you sell or make similar products?

Sign up to europages and have your products listed

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ FD is a large state-of-the-art xenon flatbed instrument. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. XXL+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-30 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance 300-400 nm / 340nm or 420nm Measurement and Control of Black Standard (BST); (Black Panel optional) Measurement and Control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Thermal insulation of test chamber and periphery preventing water condensation Temperature control selectable either via CHT (15° * - 70 °C; *with chiller) or via CHT and BST (25° * - 100 °C; *with chiller) simultaneously (dual control) Adapted chiller SunCool XXL+ for testing at low temperatures in the range 15-30°C CHT; detachable for standard weathering testing needs Ultrasonic humidification system for controlled humidity during operation without SunCool Specimen spray system with integrated 60 l water reservoir for spray cycles at 25°C ** - 70°C Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Sliding sample table for easy specimen loading; exposure area (WxD) 74 x 37 cm

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ is a large state-of-the-art xenon flatbed instrument. The 3000 cm2 test chamber is perfect for high volume weathering testing of large flat or 3-D specimen. SUNTEST XXL+ offers a complete set of features ideal for standard testing covering all common industry weathering standards. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and control of Irradiance 300-400 nm / 340nm or 420nm Measurement and control of Black Standard (BST); (Black Panel optional) Measurement and control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Ultrasonic humidification system for humidity control Specimen spray system with integrated 60 l water reservoir Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Various specimen holders to hold different panel sizes. XenoCal sensors to calibrate BST and irradiance. Large variety of filter systems: coated and uncoated quartz, special UV glass, daylight filter, window glass, Solar ID 65, Solar Standard, to meet various spectral specifications in standards.

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest 440 is a highly versatile xenon weathering instrument for a variety of materials. Designed for fast and economical testing, the Xenotest 440 utilizes XenoLogic™, a revolutionary new twin-lamp operating technology which enables high irradiance levels of 120 W/m 2 of total UV radiation. In addition, XenoLogic provides extended lamp service life. With this new technology, the two xenon lamps combined can last over 4000 hours under standard testing levels of 40-60 W/m 2. 2 x 2200W air-cooled xenon lamps 2310 cm 2 exposure area XenoLogic TM lamp operating technology for extended lamp service life Touch screen with color display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Direct Setting and Control of Relative Humidity Display of Diagnostic Messages Storage for 10 user-defined tests Multi-Language Capability: English, German, Italian, French, Spanish, Turkish, Dutch, Polish, Hungarian, Czech, Japanese, Korean, Chinese On-rack XENOSENSIV® RC-34 BST for measuring and controlling irradiance (in W/m²) in the wavelength range 300-400 nm and BST (°C) on specimen level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 115 °C) simultaneously Fan-controlled temperature difference between BST and CHT Ultrasonic humidifier controlling relative humidity in the range 10-75% (Light cycle) Integrated 60 litre water reservoir for humidity control and specimen spray (automatic refill) Specimen spray system Rotating specimen rack with 38 test positions (13.5 cm x 4.5 cm); 33 (10.0 cm x 6.8 cm); 22 (13.5 cm x 5.5 cm); 11 (29.5 cm x 7.0 cm) Pre-programmed lightfastness and weathering standards Outer cylinder made of special UV glass UV-protected test chamber window Internal memory chip for storing instrument data Data output via Memory Card or serial interface RS232 Ethernet interface for XenoTouch Add-ons (Remote Control, E-Mail Service, Online Monitoring) XENOSENSIV RC-420 BPT

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ FD is a premium stand-alone rotating rack xenon instrument with 4000cm2 exposure area. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. Beta+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-50 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. Beta+ FD offers two custom racks - a bottle rack and a packagings rack. Both carry loads up to 20 kg and fit various packaging shapes and sizes. Economic non-aging filters guarantee realistic simulation of all three common light conditions - outdoor Daylight / indoor Daylight / Supermarket light, while a chiller keeps test temperatures on realistic levels even at high irradiance. Programming and monitoring can be done online. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct setting and control of Irradiance (300-400 nm) or (300-800 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Display of Diagnostic Messages Storage for 10 user-defined test methods Multilingual User Interface Test chamber with rotating rack technology; for application-specific specimen racks Thermal insulation of test chamber and periphery preventing water condensation Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window Optional StoreLight filter to simulate supermarket light conditions On-rack XENOSENSIV 300-400 nm or 300-800 nm sensor for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by CHT (10° *- 70°C; *with chiller) or by CHT and BST (25° * - 120°C) simultaneously (dual control) Fan-controlled temperature difference between Chamber and Black Standard Temperature Chiller SunCool Beta+ for extended CHT- and BST-ranges towards lower temperatures UV-protected test chamber window Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Internal memory chip for storing instrument data Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Ci3000+ Weather-Ometer and Fade-Ometer with their advanced digital control systems, represent monumental achievements in applying digital and optical technologies in easy-to-use laboratory weathering instruments. The 3000 Series is approved by many OEMs in the textiles, paints & coatings and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The 3000 Series has been certified CE, UL, CSA, ISO and EN compliant. Key features of this instrument include: a rotating sample rack to maximize uniformity over all specimens; custom designed nozzles to provide uniform specimen and rack spray; ASTM Black Panel Thermometer or ISO/DIN Black Standard Thermometer to control and monitor temperature at specimen level to ensure test repeatability. 4500 W water-cooled xenon arc lamp Total exposure area of 2,188 cm 2 (339 in 2) TFT full color 12" touch screen control panel display of all test parameters Direct setting and control of Black Panel Temperature; uninsulated (BPT) or insulated (BST) Direct setting and control of relative humidity Direct setting and control of specimen chamber air temperature Display of diagnostic messages 14 factory pre-programmed test methods (Weather-Ometer); 6 factory pre-programmed test methods (Fade-Ometer) Space for 12 custom programs; sub-cycle capability Multi-language capability (English, French, German, Spanish, Japanese, Chinese, Korean, Turkish) Streaming data output via ethernet or USB port. USB thumb drive included SmartDamper TM to reduce test variability in chamber temperature and humidity and compensates for changes in ambient lab conditions SmartLight Monitor TM verifies that correct light capsule is installed Filter combinations available to meet all common test methods Air intake dust filter CS-7 xenon lamp cooling system Chamber viewing window in door Universal electrical configurations to meet local frequency, voltage, and electrical requirements Meets CE, UL, ISO EN and CSA safety requirements Automatic test countdown based on time or radiant exposure VibraSonic TM Humidification System Specimen Holders available to accommodate many sample types Calibrated xenon reference lamp Water purity indicator Dual Black Panel Temperature (BPT) and Black Standard Temperature (BST) Measurement/Control including uninsulated BPT and BST sensors Monitoring of second wavelength: 300-400 nm, 340 nm or 420 nm including beam splitter, dual filter housing and lamp calibration Special locking casters and frame modification WXView (Weather View) Data Acquisition System 2-tier rack - 60 specimen positions

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Ci4000 Weather-Ometer, with its advanced digital control system, represents monumental achievement in applying digital and optical technologies in an easy to use laboratory weathering instrument. The Ci4000 is approved by many OEMs in the automotive, paints and coatings, and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The Ci4000 has been certified CE, UL, CSA, ISO and EN compliant. 6500 W water cooled xenon arc lamp system Total exposure area of 6,500 cm 2 (1,008 in 2) 3-tier inclined specimen rack TFT full color 12" touch screen control panel display of all test parameters Direct setting and control of irradiance: 340nm, 420nm, 300-400nm or Lux Direct setting and control of Black Panel Temperature; uninsulated (BPT) or insulated (BST) Direct setting and control of relative humidity Direct setting and control of specimen chamber air temperature Display of diagnostics messages 14 factory pre-programmed test methods Space for 12 custom programs; sub-cycle capability Multi-language capability (English, French, German, Spanish, Japanese, Chinese, Korean, Turkish) Streaming data output via ethernet or USB port. USB thumb drive included SmartDamper TM to reduce test variability in chamber temperature and humidity and compensates for changes in ambient lab conditions SmartLight Monitor TM verifies that correct light capsule is installed Specimen and rack spray Filter combinations available to meet all common test methods Air intake dust filter CS-7 xenon lamp cooling system Water purity indicator with alarm Calibrated xenon reference lamp Chamber viewing window in door Universal electrical configurations to meet local frequency, voltage, and electrical requirements Meets CE, UL, ISO EN and CSA safety requirements Automatic test countdown based on time or radiant exposure Specimen Holders available to accommodate many sample types VibraSonic TM Humidification System Dual Black Panel Temperature (BPT) and Black Standard Temperature (BST) Measurement/Control including uninsulated BPT and BST sensors Monitoring of second wavelength: 300-400 nm, 340 nm, 420 nm or Lux Refrigeration coils installed in air duct (does not include required refrigeration unit) S 3T Specific Specimen Surface Temperature system WXView (Weather View) Data Acquisition System LiquiAir TM self contained xenon lamp cooling system (top or wall mount available) Chamber air and DI water refrigeration

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Ci5000 is approved by many OEMs in the automotive, paints & coatings and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The Ci5000 has been certified CE, UL, CSA, ISO and EN compliant. Unmatched Repeatability and Reproducibility Design and engineering innovations in the airflow, irradiance and control systems have dramatically reduced variability in critical test parameters. As a result, the Ci5000 achieves new levels of temperature, humidity and light exposure uniformity. Now available in a low voltage model (240V) and standard voltage model (480V) depending on incoming power configurations at the customer's location. 12000 W water cooled xenon arc lamp system Total exposure area: 11,000 cm 2 (1,705 in 2) 3-tier inclined specimen rack TFT full color 12" touch screen control panel display of all test parameters Direct Setting and control of Irradiance: 340nm, 420nm, 300-400nm or Lux Direct setting and control of Black Panel Temperature; uninsulated (BPT) or insulated (BST) Direct Setting and control of relative humidity Direct setting and control of specimen chamber air temperature Display of diagnostic messages 14 factory pre-programmed test methods Space for 12 custom programs; sub-cycle capability Multi-Language capability (English, French, German, Spanish, Japanese, Chinese, Korean, Turkish) Streaming data output via ethernet or USB port. USB thumb drive included Smart Damper TM to reduce rest variability in chamber temperature and humidity and compensate for changes in ambient lab conditions SmartLight Monitor TM verifies that correct light capsule is installed Specimen and rack spray Filter combinations available to meet all common test methods Air intake dust filter CS-7 xenon lamp cooling system Water purity indicator with alarm Calibrated xenon reference lamp Chamber viewing window in door Universal electrical configurations to meet local frequency, voltage and electrical requirements Meets CE, UL, ISO EN and CSA safety requirements Automatic test countdown based on time or radiant exposure Specimen Holders available to accommodate many sample types VibraSonic TM Humidification System Dual Black Panel Temperature (BPT) and Black Standard Temperature (BST) Measurement/Control including uninsulated BPT and BST sensors Monitoring of second wavelength 300-400 nm, 340 nm, 420 nm, or Lux Refrigeration coils installed in air duct (does not include required refrigeration unit) S 3T Specific Specimen Surface Temperature system WXView (Weather View) Data Acquisition System LiquiAir TM self contained xenon lamp cooling system (top or wall mount available) Chamber air and DI water refrigeration XenoCal irradiance calibration device for independent irradiance calibration and measurement at the sample plane High Irradiance capabilities available with custom rack designs (Ci5000 HE)

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The thermal incinerator (TI for short) is a system which converts gas or vaporous pollutants found in exhaust gas into non-polluting compounds by way of direct combustion. This machine is characterized by: The thermal incinerator (TI for short) is a proven and robust plant for the conversion of organic pollutants (VOCs, etc.). Today it is used especially for processes which involve high exposure to condensation or dust, or for specialized solutions requiring greater heat recovery potential. An example of this would be exhaust gases containing plasticizers or siloxane. The modular design of the combustion chamber and heat exchanger especially is conducive to servicing and cleaning compared to other designs. The polluted air is forced by means of a centrifugal fan into the tube bundle heat exchanger where it circulates around the tube bundle in a cross-current fashion. The heat exchanger can be designed for an efficiency of up to 70%. The pollutants are converted in the combustion chamber at a temperature of around 760 °C. After extensive heat transfer to the raw noxious gas, the cooled clean gas leaves the plant, where it can be supplied to various heat recovery systems (or a combination of several). The auxiliary burners can be operated with natural gas or propane or light heating oil.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The software for process monitoring from FESSMANN is the simple answer to complex production processes with its operatorfriendly, Windowsbased control. FOOD.LOG provides an overview of all data required for quality assurance of your products. The ergonomic, intuitive user guidance and storage of all data in a database make it simple for FOOD.LOG users to monitor multiple systems at once. Choose between FOOD.LOG basic, professional and enterprise in order to meet your individual demands to production monitoring. FOOD.LOG will make sure that you miss nothing. All system and operating conditions can be documented precisely. Processrelevant data such as chamber and core temperatures, Fvalue, process duration or relative humidity are recorded by the program and saved. FOOD.LOG permits precise production control and evidence, also according to DIN ISO 9000. You can comfortably create and edit goods programs from anywhere.

Request for a quote

METMANN

Spain

Our modules to increase the air temperature incorporate a combustion chamber and heat exchanger with high thermal performance, it has an insulated exterior paneling and a temperature control panel to order the start and stop of the burner and the fan. Our modules to increase the temperature are designed to be applied in drying process facilities where it is required to increase the temperature of the air driven by an external air fan. Depending on the air flow, the thermal increase can range from 20ºC to 60ºC. The air flow treated by the equipment can range from 2,150 m3/h to 18,000 m3/h depending on the selected model. The fuel used by the burner can be diesel, natural gas or propane gas.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

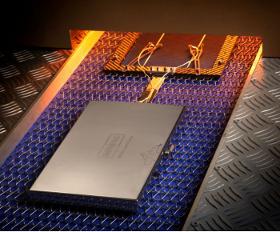

Dedicated temperature profiling solutions for — Anti-reflection coating & Thin-film deposition — Silicon PV manufacturing: contact drying, contact firing — Lamination Benefits — Measure product temperature uniformity across the process chamber(s) — Optimize the process by reducing energy costs and/or increasing throughput — Troubleshoot the process quickly and easily — Track process stability

Request for a quoteResults for

Temperature chamber - Import exportNumber of results

39 ProductsCategory

- 3D printers (5)

- Cooking and smoke-curing equipment for delicatessens (3)

- Testing equipment (3)

- Oil-fired power stations, installations and equipment (2)

- Bakery - machinery and equipment (1)

- Bakery ovens (1)

- Beauty salons - equipment (1)

- Fruit, frozen and deep-frozen (1)

- Heat pumps, domestic (1)

- Hot-air generators (1)

- Induction heating systems (1)

- Measurement - Equipment & Instruments (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Sandblasting equipment (1)

- Tea (1)