- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aluminium oxide

Results for

Aluminium oxide - Import export

ALUSELL

Turkey

Our partners aim to achieve excellent production by amazing clients with high quality and express delivery times.

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o3) 96% ceramic plates are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. Alumina ceramic substrate / plate specification: > 10x10x1mm, 20x20x2mm, 40x40x8mm, 100x60x8mm, 150x150x12.5mm, 200x200x25mm etc. > The thickness of ceramic plate ranges from 0.25 to 1.0mm Can be made according to your requirements.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Aluminum oxide (Al2o396%) ceramic substrate are widely used in thick-film circuit of electronics industry. Large scale integrated circuit,power hytrid IC,semiconductor package,pieced -film reistor, network,resistor, focusing potentiometer etc.According to the demands of customers,our company can manufacture products of special types and specifications. The Maximum dimension of ceramic plate is 138x138mm and the thickness of ceramic plate ranges from 0.25 to 1.0mm. Features: 1.High reliablility and sfety; 2.High density and mechanical properties 3.High electrical and thermal loading perormances 4.Low dilelectic loss and other characteristics

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories made by aluminum, which used in many fields ,such as industrial, medical equipment and other industries.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

PRECISION CERAMICS

United Kingdom

Precision Ceramics has introduced a new and exciting range of advanced ceramic tubes and insulators ideally suitable for thermocouple protection in high temperature measurement applications. The alumina-based tubes are used throughout many industries to aid monitoring the stability and performance of production processes especially those within hostile and aggressive chemical environments at temperatures up to 1,700°C. They are manufactured to DIN V ENV 12212 and are very strong, organically inert and well proven in a wide field of applications.

Request for a quote

WMC SINTERSTAR AG

Switzerland

From: Aluminium oxide Crocus Silicon carbide

Request for a quote

GURTEC GMBH

Germany

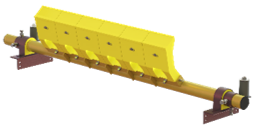

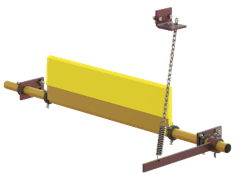

Belt width: 500-1400 mm Recommended speed: max. 3.0 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1400 mm Recommended speed: max. 3.0 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

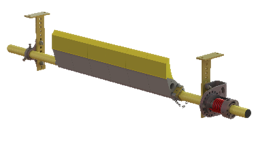

Belt width: 1200-2400 mm Pulley diameter: 800-1500 mm Recommended speed: max. 4.5 m/s Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1400 mm Pulley diameter: 320-630 mm Recommended speed: max. 3.0 m/s Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quote

PRECISION CERAMICS

United Kingdom

Alumina is the more common name of aluminium oxide. It is a hard-wearing technical ceramic offering an excellent combination of both mechanical and electrical properties and is ideally suited to a wide range of industrial applications.

Request for a quote

GURTEC GMBH

Germany

Belt width: 500-1800 mm Pulley diameter: 320-630 mm Recommended speed: max. 3.5 m/s Quick and simple exchange of wear parts Blade material: polyurethane (optional + aluminum oxide granulate)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MBW GRUPPE

Germany

The anodising process used at mbw is used for the surface treatment of die-cast aluminium. By anodic oxidation, wear and corrosion resistance, as well as the natural protective coating of the base material, are improved. Anodising increases wear and corrosion resistance. This process is suitable for rack goods

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Sandblasting Cabinets are designed for dust-free sandblasting of small and medium-sized parts in the cabinet. Air consumption is less compared to pressurized cabins. Thanks to the cartridge filter coupled to the back of the cabinet, a clear view is provided during sandblasting. Steel grit/steel ball-like granules are not used in vacuum blast cabinets! Only suitable for use with aluminum oxide, silica, garnet, glass ball, and plastic granules!

Request for a quote

PEMAT S.C.

Poland

The flat blade for cutting steel is made of aluminum oxide. It is designed for cutting: hard and soft steels, cast iron, cast steel, aluminum in the form of bars, sections, pipes, plates, thin profiles and sheets, and for transverse cutting of metal bars and wires. TECHNICAL DATA: Outer diameter - 230 mm Dial thickness - 2.0 mm Inner diameter - 22.23 mm Shape - flat Granulation type - A (alumina) Grain thickness - 46 Maximum rotational speed - 6,600 rpm Maximum linear speed - 80 m/s.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina, also known as aluminum oxide (Al2O3), is the most mature and commonly used technical ceramics. With excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina content ranging from 80% to more than 99% according to different application. It's widely used in automotive, petro-chemical, fluid contro, material transfer, industry, electrical and electronic, semiconductor,etc... - High Temperature Ability - Abrasion Resistant - Wear Resistance - Chemical Resistance - Electrical Insulator - Corrosion resistant - High compressive strength - High mechanical Strength - Resists strong acid and alkali attack at high temperatures - Excellent electrical insulation properties - Decent thermal conductivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Industrial alumina ceramic crucible is used for testing laboratory and a variety of industrial analysis.We can supply 99% and 99.5% alumina ceramic crucible and zirocnia ceramic crucible according to customer's drawings, samples and performance requirement. Alumina ceramic crucibles include: 1.arc alumina crucible 2.square alumina crucible 3.rectangle alumina ceramic crucible 4.columnceramic crucible 5.other shaped alumina ceramic crucible Overview of Physical Properties: 1. High chemical etching resistance. 2. High temperature up to 1800°C(Alumina) and 2400°C(Zirconia) 3. Resistant to sudden cold and hot, un-explosive. 4. High density of slip casting.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

High Hermeticity Metallized Ceramic Bushing /Innovacera Features: 1.Material: 96% Aluminia(AL2O3) 2.Coating Layer:Molybdenum-Mananese(Mo/Mn) 3.These metallized ceramics are ideal for high voltage, high vacuum and high pressure applicationos. So far the most widely-used and effective method for creating a leak-tight, robust joint between ceramic and metal is by brazing . A thin layer of metal deposited on a ceramic part enables brazing between ceramic and metal part that h as a different coefficient of thermal expansion. A layer of Molybdenum-Manganese is deposited with a typical thickness of 8 to 30 µm after sintering. The metallized surface receives a secondary coating of nickel to seal and improve wettability for later brazing.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminum Oxide Ceramic is wildely used in many fields including mechanical, electronics, electrical, semiconductor, automotive,textile, etc. For the good propertities, more and more customers choose Alumina ceramic materials for their applications. Alumina Ceramic can be made to Ceramic Nozzles, Ceramic Sprayers Cyclones, Ceramic Linings, Milling Systems, Ceramic Thread guides, etc.Customized designs are very often to be made. Alumina Ceramic Properties: 1. Good electrical insulation 2. Moderate thermal conductivity 3. High corrosion and wear resistance 4. Good gliding properties 5.High mechanical strength 6. High compressive strength 7. High hardness

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic-to-Metal Seal The Ceramic Surfaces for Brazing, the surface must be metallized. Compare to Glass seal, Ceramic seal has exceptional resistance to thermal and mechanical shock as well as corrosion. While it requires more complex manufacturing processes and sophisticated engineering, the price is obviously higher.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

About Beryllium Oxide (BeO) Ceramic: No other oxide ceramic material collectively exhibits these highly desirable properties and characteristics. BeO ceramic conducts heat more quickly than virtually all metals with the exception of copper and silver. Beryllia exhibits extremely low dielectric loss characteristics, possesses high electrical resistivity, and offers excellent strength with high specific stiffness properties. BeO provides all the desirable physical and dielectric characteristics exhibited by an aluminum oxide or aluminum nitride, in addition, offers thermal conductivity ten times higher than alumina, and fifty percent higher than aluminum nitride, a dielectric constant that is lower than both alumina and aluminum nitride, and weight per given volume that is fully a quarter less than alumina, and nearly ten percent less than aluminum nitride. As a thermally conductive and electrically insulating material, its performance is exceeded only by that of the diamond.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Anodizing stands for electrolytic oxidation of aluminum and is a process for strengthening the natural oxide layer present on aluminum through anodic oxidation. Unlike traditional electroplating processes, anodizing dissolves the top layer of aluminum and converts it into aluminum oxide. The resulting oxide layer protects the underlying workpiece from corrosion.

Request for a quoteResults for

Aluminium oxide - Import exportNumber of results

176 ProductsCountries

Category

- Ceramics, industrial (28)

- Steels and metals - surface treatment and coating (25)

- Cosmetics (9)

- Natural abrasives (9)

- Ceramics (6)

- Ceramics, refractory (6)

- Infrared tubes (6)

- Mineral oxides and peroxides (3)

- Safety equipment, work (3)

- Abrasive discs (2)

- Aluminium coatings (2)

- Ceramic manufacturing - machinery and equipment (2)

- Conveyor belts (2)

- Food Processing (2)

- Hygrometers (2)

- Machine tools, metal machining - parts and accessories (2)

- Metal brushes (2)

- SWEETS (2)

- Sand blasting - steels and metals (2)

- Anhydrides (1)