- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- apron feeders

Results for

Apron feeders - Import export

UGUR MAKINA CRUSHING & SCREENING

Turkey

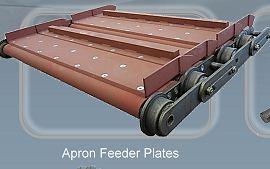

Apron feeders can operate horizontally or at an incline. In general, an Apron Feeder consists of overlapping abrasion-resistant pallets that are fastened on the chain with bolts, working like a conveyor. These chains, to which the pallets are attached, are driven by chain gears located on both sides

Request for a quote

NOVELTY STEEL

Turkey

A screw feeder is primarily designed for handling very low-tonnage outputs, with a critical requirement for positive and controlled material discharge. This type of feeder offers the advantage of easy enclosure, making it effective at preventing the release of dust. Consequently, it allows for a sealed hopper and chute arrangement from the hopper to the delivery point. The basic structure of a screw feeder includes a helical screw that rotates below the hopper outlet and is driven by an external power source. The screw can have a fixed pitch or a variable pitch with smaller spacings in the rear and gradual increases in pitch towards the discharge end. This design ensures that the material moves efficiently within the rear portion of the hopper. Novelty Structures supplies various type of Feeders for Mineral Processing Plants. * Belt Feeders * Screw Feeders * Apron Feeders * Rotary Table Feeders

Request for a quote

NOVELTY STEEL

Turkey

A belt feeder is comprised of an uninterrupted rubber belt that is supported by closely spaced idlers and propelled by end pulleys, commonly known as the head and tail pulleys. This entire assembly is enclosed within a single framework. The motor can be installed on the ground or on a separate frame and drive the feeder through the use of V-belts. Typically, the belt feeder is positioned beneath a hopper with a long, narrow slot-like opening. It allows the material to be fed along the length of the hopper. Belt feeders typically come in a range of widths from 0.6 to 1.8 meters and lengths spanning from 1.5 to 4.6 meters. The capacity of a belt feeder is determined by the width of the belt and the speed at which it moves. In practice, the capacity of belt feeders generally falls within the range of 4.5 to 2,270 tons per hour. Novelty Structures supplies various type of Feeders for Mineral Processing Plants.

Request for a quote

NOVELTY STEEL

Turkey

Apron feeders come in varying widths, ranging from 0.6 to 3.0 meters, and lengths spanning from 2.4 to 30.5 meters. Lengths exceeding 4.6 meters are primarily used for material conveyance rather than being an integral part of the feeder. Apron feeders exhibit capacities ranging from 91 to 2,270 tons per hour. The power requirements for apron feeders are approximately twice as high as those for comparable belt feeders. Apron feeders are typically employed in situations involving truck dumps or other scenarios where very coarse materials are handled, such as in the feeding of primary or secondary crushers. When an apron feeder is intended for use under a truck dump hopper with an elongated hopper opening, it’s essential to design the hopper with a taper that widens in the direction of horizontal flow for belt feeders. Novelty Structures supplies various types of feeders such as; * Apron Feeders * Belt Feeders * Rotary Table Feeders * Screw Feeders

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Apron feeders - Import exportNumber of results

5 ProductsCountries

Company type