- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assembly of sub-assemblies

Results for

Assembly of sub-assemblies - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

DIETZ GMBH

Germany

We can produce the parts you require using specific tools or on special-purpose machines. We produce complex forms and assembly parts with strip thicknesses of 0.10 to 3.00 and with strip widths of up to 100 mm – depending on the material used. The manufacturing processes that we offer include: Punching, forming, embedding, welding, bolting, riveting and mounting. We perform the assembly of small batches by hand, while larger volumes are performed automated if you so wish. Our hybrid sub-assembly production includes the over-moulding of punched parts made of wire or metal with a variety of plastics or silicones. In order to ensure that the desired braking element features optimum properties, we make use of both the temperature durability and the haptic advantages of silicone and the weight advantage of plastic when combining these materials in this fashion. Guide tube assemblies, a combination of springs and tubes, are part of the hybrid component portfolio.

Request for a quote

DIETZ GMBH

Germany

To ensure safe transport and enable an easy handover of the products during later industrial processes and assembly, we ship our springs and sub-assemblies in special packaging. Any conceivable special packaging is adapted precisely to the product in question, e.g. blister or polyethylene packaging. Tube packaging: Compression springs are transported in tube packaging. Tube packaging ensures that they can be inserted without problems, down to the last spring. Sub-assemblies, bent strip parts and laser-generated samples are transported in blister or polyethylene packaging to protect them during transport and storage. Modifying specific extraction mechanisms: We would also be pleased to assist you with our expertise regarding the modification of specific extraction mechanisms. This eliminates downtime of highly complex assembly equipment caused by springs getting caught up in one another.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Laser Micro-Welded Sub-Assemblies

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Polymer catheter shafts and components, as well as insulated wire and cable, can be precisely machined through non-contact laser ablation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

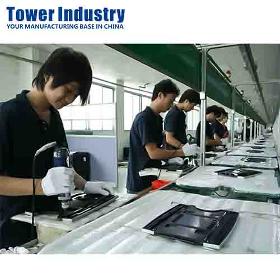

NINGBO TOWER INDUSTRY CO.,LTD

China

We almost have all the process in house, including machining(cnc milling, cnc turning, grinding), sheet metal fabrication(laser cutting, stamping, deep draw, bending, tube bending, welding). So we are very suitable for the production of finished products, assembly parts in house, which can have better price and better control on quality also.

Request for a quote

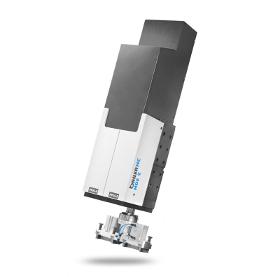

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable up to max. 250 1/min. Press: nominal stamping capacity 500 kN, stroke 15 - 63 mm, with SP 500 Servo units: max. nominal forming capacity 40 kN, max. stroke 120 mm Feed length: servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 250 mm, max. wire Ø 4 mm Dimensions: depending on type Weight: depending on type

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable up to max. 250 1/min. Press: nominal stamping capacity 300 kN, stroke 60 mm Servo units: max. nominal forming capacity 40 kN, max. stroke 120 mm Feed length: servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 60 mm, max. wire Ø 4 mm Dimensions: depending on type Weight depending on type

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 150 1/min. Press: nominal stamping capacity 300 kN, stroke 16 mm (stronger presses on request) Slide units: max. nominal forming capacity 120 kN, max. stroke 95 mm Feed length: mech. feed: max. 500 mm, with feed cycle reduction, servo feed: any feed pitch (as option) Material: max. strip thickness: 10 mm, max. strip width 160 mm, max. wire Ø 10 mm Dimensions: width 3,130 mm x depth 2,100 mm x height 3,100 mm (with protection unit) Weight: approx. 16,000 kg (without units and tooling)

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Stroke rate: continuously variable from 5 to max. 700 1/min. Press: nominal stamping capacity 300 kN, stroke 10 mm Slide units: max. nominal forming capacity 50 kN, max. stroke 10 mm Feed length: mech. feed: max. 120 mm or 240 mm, with feed cycle reduction, servo feed: any feed pitch Material: max. strip thickness: 4 mm, max. strip width 80 mm, max. wire Ø 4 mm Dimensions: width 2,950 mm x depth 1,400 mm x height 2,190 mm Weight approx. 7,500 kg

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Vertical stroke: max. 60 mm Horizontal stroke: max. 150 mm Positioning accuracy: +/- 0,02 mm Repeat accuracy: +/- 0,01 mm Handling weight: max. 1,5 kg Pulse rate: max. 100 1/min.

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications: Pulse rate: max. 200 1/min Processing radius: max. 100 mm Vertical stroke: max. 120 mm

Request for a quote

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

Specifications Stroke rate: continuously variable from 5 to max. 250 1/min. Press: nominal punching capacity 400 kN, stroke 20 mm Slide units: max. nominal forming capacity 90 kN, max. stroke 95 mm Feed pitch: servo feed: any feed pitch, mech. feed: max. 500 mm, with feed cycle reduction Material: max. strip width 80 mm, max. wire diameter 6 mm Dimensions: width 3,930 mm, depth 1,595 mm, height 2,220 mm Weight: approx. 4,500 kg (without tooling)

Request for a quote

BERTHON MJM BOATING-WORLD

United States

Features Fully submersible IPX8 rated battery housing system. Easy access charging connector with a 4 hour charge time IPX8 rated electric motor 460 watts of pedal assist power Up to 4 hours of riding time on the lowest assist level and 1.5 hours on maximum assist Please note, estimated battery run time may vary depending on the weight of the rider, weather conditions, and level of assist. Chassis & Gears Resilient against saltwater and corrosion. The Hydrofoiler’s frame and gears are packed full of ingenious design details that stay true to the simplicity of a beautifully crafted bike. Features Aircraft-grade, TIG-welded 6061-T6 aluminium frame Hybrid drivetrain with industry standard components for easy replacement Buoyancy modules designed to streamline the Hydrofoiler both above and below water Easy maintenance crank-set sub-assembly, gearbox sub-assembly, and the propeller/shaft sub-assembly Carbon Fibre Foils This combination is impeccably tuned.

Request for a quoteResults for

Assembly of sub-assemblies - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Metallurgy - machinery and installations (3)

- Machine tools - metal shaping (2)

- Fishing boats - equipment and materials (1)

- Import-export - medical and surgical equipment (1)

- Industrial Vehicles (1)

- Machine tools - metal machining (1)

- Mechanical engineering - custom work (1)

- Medical Equipment (1)

- Motor mechanics - hand tools, non power (1)

- Packaging (1)

- SMALL METAL PARTS (1)

- Stamping - machine tools (1)