- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- balancing machines and systems

Results for

Balancing machines and systems - Import export

FERPLAST SNC

Italy

The LARGE Spring balancers allows to effortlessly lift gluing machines, stapling machines, nailing machines, strapping machines and other tools with weight from 15,0 to 180 Kg The balancers are an essential tools to ease the operator work and increase productivity. They also reduce the processing time and help improve the quality of work. The balancers are manufactured according with the DIN 15112. The Large and Extra Large series balancers can be equipped with optional: - BA: control device from the bottom - RE: rotating device and isolation

Request for a quote

FERPLAST SNC

Italy

The MEDIUM Series spring balancers allow to effortlessly lift gluing, stapling, nailing, strapping and other tools with weight from 4,0 to 25 Kg. The balancers are an essential tools to ease the operator work and increase productivity. They also reduce the processing time and help improve the quality of work. The balancers are manufactured according with the DIN 15112. MODELS WITH BRAKE The models with brakes (models marked with the letter F), are equipped with clutch/brake that controls the rotation speed of the drum, going from a slight slowing down to complete blocking. To increase or decrease the friction and to make each position of the drum more stable, it is possible to act on the clutch/brake screw. Warning: it is absolutely forbidden to act on the clutch / brake screw when the rope is protruding or without load.

Request for a quote

FERPLAST SNC

Italy

Small balancers are used to correct effortlessly glue, staplers, nailers, strapping tools and other tools from 0.4 to 14 kg. The balancers are an essential tools to ease the operator work and increase productivity. They also reduce the processing time and help improve the quality of work. The balancers are manufactured according with the DIN 15112. MODELS WITH BLOCK The models with the block (models marked with the letter B), are equipped with a Device That Allows to block the stroke with a simple operation on the load. The stroke is stopped at 100 mm intervals.

Request for a quote

FERPLAST SNC

Italy

STURDY BIG BAG HOLDER Big Bag lifting beam with 2000 kg capacity suitable for lifting and handling the classic Big Bags 90x90x120 cm. The grip of the big bag is very safe and takes place by hooking it on the 4 corners. The lifting beam can be installed on the forks of a lift truck by placing it in the appropriate seats or it can be used with a crane or bridge crane.

Request for a quote

TUNA WEIGHING AND ELECTRONIC SYSTEM

Turkey

Features Robust construction suitable for heavy conditions Painted or stainless steel Stainless steel waterproof load cells in IP 68 protection class Fully electronic measurement from multiple points Dual indicator indicator as weight and information display Automatic multi tare Printer output Computer output External indicator output Date and time CE certified

Request for a quote

CIMAT

Poland

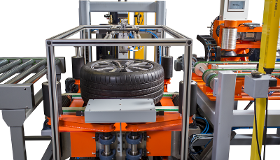

The balancing process includes a measurement of the workpiece unbalance and mass correction. Both operations are controlled by the measurement processing module with ROTORTEST 9.5 software. Static balancing is the process of addressing the unbalance of a component in a single plane only, as opposed to dynamic balancing. Static balance is at play when the center of gravity of a unit is on the axis of rotation. This machine balances a wide variety of rotors including grinding wheels disc brakes refinery plates fans composite material propellers clutches pulleys tires wheels CIMAT Static Balancers Low operating and maintenance cost Low maintenance Simply set it up, no groundwork is needed Nonrotation, simple and precise balancing No safety device required Short measuring times Efficient measuring unit operation by Touch Screen If you would like to know more about static balancing, please get in touch with our team today by calling

Request for a quote

CIMAT

Poland

Suitable for a manual operation by operator, Suitable for an automatic cell with a robot load/unload, Suitable for an automatic conveyor production, Wheel presence sensors, Imbalance compensation of a spindle, Ergonomic size of the machine, Sophisticated fluids drain system with reservoir, Spindle protection system from metal chips, Automatic clamping of a wheel hub with a heavy duty pneumatic clamping chuck, Automatic brake and wheel positioning, Fastest balancing cycle time, Fastest tool changeover time, Made of wellknown brands heavy duty components, Servomotor as a spindle drive motor, Software capabilities Valve compensation feature, The best quality, automatic display, Password protection access for operator and shift manager, Any language possible, Industry 4.0 compliant, Static and dynamic imbalance display, Autotest and selfcalibration, Data transfer and communication with master station, CSV file data creation Sophisticated remote diagnostic and support software .

Request for a quote

CIMAT

Poland

High accuracy and efficiency are guaranteed thanks to special software that distributes unbalance to different counterweights for drilling. Onsite drilling station that can travel in different directions and provides fast and easy mass correction. Custom balancers are available upon request. Balancing reports can be saved as a PDF, CSV or XLS and can be sent to a builtin printer or to an ERP system—summary reports can also be created on request Safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant. Permanent calibration and rotor specific calibration as standard Latest measuring and control unit ROTORTEST based on microprocessor technology

Request for a quote

CIMAT

Poland

CMTTWV2M—an automatic balancer for turbine wheel of a turbocharger, which can be equipped with a manipulator for component loading and unloading. The machine is equipped with the latest, most costeffective milling station technology. The unique feature of the CMTTWV2M is that it can balance a wide range of turbine wheel weights—the weight range of the balancer is wider than similar machines on the market. Air bearing technology is a standard feature on the CMTTWV2M. CMTCWV2M – automatic balancer for compressor wheel of a turbocharger, which can be equipped with a manipulator for component loading and unloading. The machine is equipped with a latest cost effective milling station. The unique feature of this machine is that it can balance the widest range of weight on the market today. Air bearing technology is applied as a standard feature. CMTCWV2—a manual balancer for the compressor wheels of a turbocharger for R&D departments and small scale productions.

Request for a quote

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST Balancing reports are saved as a PDF, CSV or XLS, printed on a builtin printer or sent to an ERP system Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant CIMAT’s software converts amount of unbalance into predefined special balancing clips, which have to be placed on a blade according to the onscreen information Power supply connectors are connected to the motor of the fan automatically

Request for a quote

CIMAT

Poland

ROTORTEST 3.5 is a field balancer designed for dynamic balancing and diagnostics of rotors installed in various machines. This portable device enables balancing of rotors in working conditions and helps eliminate vibration problems. ROTORTEST 3.5 is a convenient instrument for balancing installed rotors, accurately and inexpensively without disassembling the machine being worked on. You can balance rotors of any size or weight in one or two balance planes. It provides you with all of the important diagnostic information such as overall vibrations, tracking analysis, and FFT frequency analysis. Roller bearing assessment is supplied as a standard feature. Roller bearing assessment performs spectrum analysis to detect periodic impacts caused by roller bearing damage and gearing damage—we will help you schedule any possible repairs and technical inspections of the equipment.

Request for a quote

CIMAT

Poland

Vertical axis balancing machines are available in one plane configuration for the measurement of the static unbalance only, or in two plane configuration for the measurement of the dynamic unbalance. Vertical Balancing machines permanent calibration enables simple machine operation and provides high measuring accuracy. CIMAT ensure flexible concepts for protective equipment, improving machine safety and simplifying work. Vertical axis balancing machines are normally used for balancing Brake discs Flywheels Pulleys Clutches Woodworking tools Tools and tool holders Fans Pump impeller Grinding wheels Vertical Balancing Machine Available as a custom balancer Precise unbalance measurement for rotors Compact machine design Balancing in one or two plates Mass correction types milling, drilling, grinding, punching, welding, adding balancing weights etc. Special balancing adapters to fit ISO, HSK, CAT or other tool holders.

Request for a quote

CIMAT

Poland

Horizontal balancing machines of CIMAT are designed to balance a wide variety of small & large rotors. With different expansion options available, like more powerful drive and specific software solutions, rotors can be balanced up to their operating speeds. According to your specific order, machines can be supplied with rotor positioning function, drilling or milling mass correction function and industrial vacuum cleaner for swarf extraction from the place of unbalance correction. Horizontal Balancing Machine High balancing accuracy Fast balancing cycle time, ensuring by hardbearing principle High quality parts Rotor applications include electric armatures spindles fans generators turbines compressors rolls crankshafts

Request for a quote

CIMAT

Poland

At CIMAT, we offer conventional horizontal balancing machines on a bed. The greatest advantage of these machines is their versatile application. With this machine different rotors could be balanced, such as discshaped, rotors with own journals as well as blowers, turbines, and many others. Main features universally applicable, custom design for every customer, permanent calibration and rotor specific calibration as standard, intuitive and easy to operate software, latest measuring and control unit ROTORTEST based on microprocessor technology, different correction methods are supported milling, drilling, grinding, punching, welding, adding balancing weights, Onsite drilling units are available, safety guarding standard ISO 21940232012 (old ISO 7475 and DIN 45690) compliant and others.

Request for a quote

CIMAT

Poland

Automated Balancing Machines for Brake Discs and Drums Machinery Directive 2006/42/EC compliant Custom balancers and adapters are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction milling, drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quote

CIMAT

Poland

Automated Balancers for Rotors of Supercharger Machinery Directive 2006/42/EC compliant Custom balancers are available Shortest delivery time Multiple station balancers are available Newest measuring and control unit ROTORTEST No component marking for speed measuring NC mass correction drilling, grinding, punching, welding, adding balancing weights etc. Machineloading is available Safety standards ISO 21940232012 (old ISO 7475 and DIN 45690) compliant

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CIMAT

Poland

At CIMAT, we offer a wide range of vertical balancing machines for tools and tool holders. As a specialist manufacturer, we also manufacture custom vertical balancing machines for tools and tool holders working at high speeds. Our balancers are extremely accurate and help to provide highquality metal processing. Unbalanced tools or tool holders lead to dangerous vibrations, rattling, and poor surface quality. Therefore, we incorporate the latest proven technology and deliver unrivaled accuracy and repeatability, and faster results, than comparable machines on the market. Advantages Machinery Directive 2006/42/EC compliant. Custom balancers are available. Special balancing adapters to fit ISO, HSK, CAT or other tool holders. Newest measuring and control unit ROTORTEST. Mass correction types milling, drilling, grinding, punching, welding, adding balancing weights etc. Safety norms ISO 21940232012 (old ISO 7475 and DIN 45690) compliant. Balancing reports are saved as a PDF

Request for a quote

CIMAT

Poland

Balancing Machines for Rail Vehicles The balancing machines from Cimat are designed according to customerspecific requirements. We can provide machines that solely measure unbalance or combination systems that include a specially developed milling unit. In order to limit installation restrictions as much as possible, Cimat’s balancing machines are for single components like railroad wheels, brake disks ring gears Semiautomatic Train Wheel Balancing Machine 3jaw chuck for wheel gripping Supports rail wheel and gear wheel Automatic 3axis milling system with chip vacuum Automatic guarding Adapted to robot integration Chip vacuum Fast measurement run High measuring accuracy

Request for a quote

CIMAT

Poland

Automatic balancers manufactured by CIMAT can balance many types of rotor, including discshaped rotors, brake discs, clutches, pulleys and rotors with journals, electric armatures, rotors of mechanical compressors, turbocharger rotors, pump rotors, rotors designed for the railway industry, others.

Request for a quote

CIMAT

Poland

CMT48 VSR is a longlife balancing machine that is incredibly accurate, efficient and user friendly. It consists of two setups, to be able to balance turbocharger cores of passenger cars and heavy duty trucks. CIMAT has developed an energysaving adapter system for its VSR machines, which consists of a plate and a sleeve – plate fixes a bearing housing of a core to the machine and a sleeve drives a turbine wheel with compressed air. Explanation of adapter system. Different turbochargers mean different dimensions—bearing housings and rotors can come in a variety of sizes. This means that if you use a oneelement adapter you have to buy a new adapter for nearly each CHRA. CIMAT’s twoelement adapter can match in pairs, resulting in a variety of configurations. A variety of configurations means less adapters. Less adapters means less overhead. With CIMAT’s innovative adapter system, 10 plates and 10 sleeves are equal to 100 traditional adapter configurations.

Request for a quote

CIMAT

Poland

CMT48 VSR BIG is a longlife balancing machine that is incredibly accurate, efficient and user friendly. It allows to balance turbocharger cores of passenger cars and heavy duty trucks. CIMAT has developed an energysaving adapter system for its VSR machines, which consists of a plate and a sleeve – plate fixes a bearing housing of a core to the machine and a sleeve drives a turbine wheel with compressed air. Explanation of adapter system. Different turbochargers mean different dimensions—bearing housings and rotors can come in a variety of sizes. This means that if you use a oneelement adapter you have to buy a new adapter for nearly each CHRA. CIMAT’s twoelement adapter can match in pairs, resulting in a variety of configurations. A variety of configurations means less adapters. Less adapters means less overhead. With our innovative adapter system, 10 plates and 10 sleeves are equal to 100 traditional adapter configurations.

Request for a quote

CIMAT

Poland

CMT48 VSR is a longlife balancing machine that is incredibly accurate, efficient and user friendly. It allows to balance turbocharger cores of passenger cars, vans and other. CIMAT has developed an energysaving adapter system for its VSR machines, which consists of a plate and a sleeve. Plate fixes a bearing housing of a core to the machine and a sleeve drives a turbine wheel with compressed air. Explanation of adapter system. Different turbochargers mean different dimensions—bearing housings and rotors can come in a variety of sizes. This means that if you use a oneelement adapter you have to buy lot of new adapters for nearly each CHRA. CIMAT’s twoelement adapter can match in pairs, resulting in a variety of configurations. A variety of configurations means less adapters. Less adapters means less overhead. With this innovative adapter system, 10 plates and 10 sleeves are equal to 100 traditional adapter configurations.

Request for a quote

CIMAT

Poland

This machine is a longlife balancing machine that is incredibly accurate, efficient and user friendly. It consists of two setups, to be able to balance turbocharger cores of passenger cars and heavy duty trucks. CIMAT has developed an energysaving adapter system for its VSR machines, which consists of a plate and a sleeve – plate fixes a bearing housing of a core to the machine and a sleeve drives a turbine wheel with compressed air. Explanation of adapter system. Different turbochargers mean different dimensions—bearing housings and rotors can come in a variety of sizes. This means that if you use a oneelement adapter you have to buy a new adapter for nearly each CHRA. CIMAT’s twoelement adapter can match in pairs, resulting in a variety of configurations. A variety of configurations means less adapters. Less adapters means less overhead. With CIMAT’s innovative adapter system, 10 plates and 10 sleeves are equal to 100 traditional adapter configurations.

Request for a quote

AUTOMATED PRODUCTION LTD

United Kingdom

APL vision inspection systems are designed for a broad spectrum of components. Quality Control Checks, Optical Character Recognition (OCR), Glass Disc Vision Inspeciton System (MK360), Code Reading, Blister & Tablet Inspection and batch sorting applications are a few examples. The systems have been developed to meet high speed quality control requirements for 100% inspection. Our experience with handling systems is key to offering a total solution when integrating vision software. Typical projects start with an evaluation of the vision parameters in order to provide a complete turn key solution.

Request for a quoteResults for

Balancing machines and systems - Import exportNumber of results

28 ProductsCountries

Company type