- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bevel gears- ground

Results for

Bevel gears- ground - Import export

ITALGEAR SRL

Italy

ITALGEAR has long promoted grounding as the most effective gear finishing for Gleason bevel helical gears and takes pride in using the latest gear grinding machine from Gleason and Klingelnberg Oerlikon. The Tooth Contact Anlalisys (TCA) to obtain the optimal motion graph curves of the bevel helical gear that will generate the lowest noise and the highest precision once in operation is developed by ITALGEAR engineers through the use of specific software like CAGE and Kimos. Quality controls are performed by software’s like GAGE and Komet throughout the entire process in order to replicate precisely the mathematical model of the tooth profile.

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

Over 3400mm dia, this Gear is manufactured by us, OGGO Tech excels at producing gears in Turkey, others include spur gears, helical gears, worm gears, herringbone gears, pto gears, pinion and racks, pinion gears, sprocket gears, bevel gears, ground gears, transmission components. Turkey gear manufacturing and We carry out our gear manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our gear sets. The selected applications in tool and gear production are determined by the part, manufacturing time periods, and eventually their dimensions. Gear manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

This Planetary Gear is manufactured by us, OGGO Tech excels at producing gears in Turkey, others include spur gears, helical gears, worm gears, herringbone gears, pto gears, pinion and racks, pinion gears, sprocket gears, bevel gears, ground gears, transmission components. Turkey gear manufacturing and We carry out our gear manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our gear sets. The selected applications in tool and gear production are determined by the part, manufacturing time periods, and eventually their dimensions. Gear manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

This Double Helical Gear is manufactured by us, OGGO Tech excels at producing gears in Turkey, others include spur gears, helical gears, worm gears, herringbone gears, pto gears, pinion and racks, pinion gears, sprocket gears, bevel gears, ground gears, transmission components. Turkey gear manufacturing and We carry out our gear manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our gear sets. The selected applications in tool and gear production are determined by the part, manufacturing time periods, and eventually their dimensions. Gear manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quote

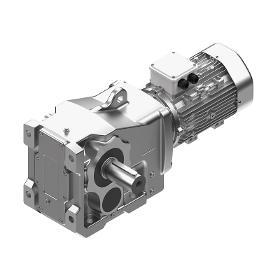

PGR DRIVE TECHNOLOGIES

Turkey

Helical bevel gear units with 90° input and output axis range. Casing with feet, flange F options. A rigid structure in case. System resistance calculations are made in accordance with ISO, DIN and NIEMANN standards. Different input options may be provided (Coupled motor, IEC, PAM, W, Servo motor connected, ...). Different output options available (Solid shaft, Hollow shaft, With shrink disc, ...).

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

With our extensive supplier portal, we can cover all your needs in the field of Gears and Bevel Gears. Trust us in choosing the right supplier for your needs

Request for a quote

NORELEM FRANCE

France

Milled toothing, straight teeth. Engagement angle 20°, bright. Axis angle = 90°. Note for ordering Bevel gears are supplied singly. To obtain a pair of bevel gears, please order the specified mating gear as well.

Request for a quote

NORELEM FRANCE

France

Injection moulded, straight teeth. Engagement angle 20°. Axis angle = 90°. Machined bores from module 1.5. Polyacetal, white. Polyketone, ivory tone. Note Polyacetal Standard material with high hardness grade and low coefficient of friction. Polyketone Material with significantly longer service life, higher power transmission and greater security against tooth breakage due to the extraordinarily high wear resistance and very good tribological properties. Can be used under water and other media. Injection moulded gear wheels may have internal manufacturerelated cavities. These may become visible during drilling or broaching. They do not impair the function. Bevel gear wheels are supplied as single components. To obtain a pair of bevel gear wheels, please order the specified mating gear as well.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

HT spur gear bevel gear spiral gear Steel quench and tempered, bronze etc. Custom made according drawing With our specialized expertise in custom gear, gear shaft, castings parts, forging parts, machined parts, welding parts for almost three decades, we can assist you on your industrial development. Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We are proud of our core competence in industry leading production processes, spectrometer analysis, critical NDT and tight tolerance machining.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company has 25 years experience for manufacture different kinds of gears.And our company has many advanced production equipments. such as CNC forming grinding wheel grinding machines, gantry machining centers, four axis and five axis machining centers, CNC lathes, CNC gear shapers, CNC milling machines, CNC hobbing machines, gear chamfering machines.and more than 40 sets of processing and testing equipment. we can provide various professional production services such as precision gear wheel machining, CNC machining, CNC turning machining, and so on.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Xian Huan-Tai has been specialized in Custom High Precision Gear, Gearbox, Gear shaft, Castings, forgings, machining parts, metal stamping parts and assembly since 1996. Material options are steel, aluminum, bronze, iron etc. We strive to provide the high quality castings and try to avoid defects delivered to our customers. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Special inspection method agreed by customers like hydraulic, gas tight test, water tight test etc.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

1, custom drawing 2, Materials: carbon steel, alloy steel, cast iron, cast steel, pig iron, grey iron, ductile cast iron and so on. 3, Has established efficient quality system and obtained international approvals ISO9001, TUV-PED, BV. 4, Produced by experienced technical staff. 5, Production capacity: more than 8,000MT per year. 6, Small orders accepted. 7, Perfect facilities. 8, Advanced machining equipment. 9, Material standards: GB,DIN,EN,NF,ISO,JIS,SS,BS,AISI,SAE,ASTM,UNS,ACI.

Request for a quote

ITALGEAR SRL

Italy

High quality lapped Gleason gears that exceed the expectations of the most demanding customers are well within the capability of ITALGEAR who will implement their long developed experience in the field and develop the most effective Tooth Contact Area and motion curves of the bevel gear resulting into high precision and low noise in operation. Specific software such as CAGE and Kimos are used as well as strict controls of all the production steps are applied in order to replicate precisely the mathematical model of the tooth profile (software such as GAGE and Komet are used). The use of modern Gleason Phoenix CNC gear cutting machines and Klingelnberg and Remaut CNC lapping machines with a 100% gear final check in combination with vibration analysis, allow to obtain highquality lapped Gleason gears that will satisfy the most demanding customers

Request for a quote

ITALGEAR SRL

Italy

Cylindrical ground gears are cut by hobbing machines of the latest generation and finished by Reischauer and Gleason CNC grinding machines equipped with automatic loaders and special software that allow the correction of the twisting errors that may occur in helical gear and, with special ground cycles strategy minimizing noise of gears in operation. ITALGEAR can also make the finishing of the gears after carburizing heat treatment adopting the Skiving technology, which allows the precise finishing of gears through superfinishing of the teeth with a hard metal PVD coated hobs. The technology allows production of groundquality precise gears while reducing cutting time and costs effective at the same time. On request, ITALGEAR engineers can team up with the Customer R&D and suggest any appropriate measures to optimize the gear meshing in order to obtain low noise in operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine and gear manufacturing of bevel gear in turkey, since 1989

Request for a quote

DAVALL GEARS LTD.

United Kingdom

Davall DSG supply all forms of gearbox up to 150Kw

Request for a quote

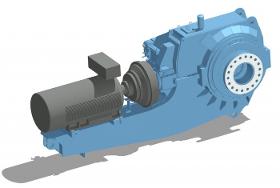

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff has been a renowned manufacturer of axle drives for rail vehicles such as locomotives and track work vehicles for more than five decades. The wheelset drives can be designed as bevel gears, spur gears or customized solutions, so that they optimally meet the performance requirements. We meet the high-quality standards in the field of transport technology thanks to our many years of experience in service and more than 2000 newly delivered final drives. Our gearboxes are robust, durable and designed for use under extreme conditions.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff gear solutions for bucket wheel excavators / stackers / reclaimers are characterised by a compact design, high adaptability and low weight. The robust gearboxes are perfectly matched to the requirements and ensure maximum availability for the mining and transport of raw materials. Our gear units are used as bucket wheel drive, travel drive or conveyor drive. When replacing existing drives, in many cases the weight can be reduced even further by increasing the performance. Advantages at a glance: — Customized solutions — Compact and weight-optimized construction — High power density — Reliable and low maintenance

Request for a quote

ERKAS MACHINE AND GEAR INDUSTRY

Turkey

ERKAS Machine supplier of spur gear, helical gear, bevel gear, rack gear in Turkey since 1989

Request for a quoteResults for

Bevel gears- ground - Import exportNumber of results

23 ProductsCompany type