- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cartridge heaters

Results for

Cartridge heaters - Import export

FRIEDRICH SCHULTZE GMBH

Germany

Screw-in heaters are versatile and intended for heating liquid media in industrial and commercial applications. When selecting, the specific surface load permitted for the respective medium must be observed and checked by the customer. EHK G2 are mainly used for heating hydraulic oil in containers in which the replacement of the heating cartridge without draining the medium must be possible. Ceramic heating cartridge in stainless steel tube ø 50mm, material-no. 1.4512 or material-no. 1.4404. G2″ thread SW70 welded from V2A. Terminal box made of PA6-GF30, impact-resistant and oil-resistant, degree of protection IP66/67. Unheated zone 50mm, surface load 1,5 W/cm², voltage 230/400 V. Special versions on request.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN ® Explosion proof cartridge heaters as direct heaters for liquids or gases in hazardous environment. These units are equipped with a heating bundle or a replaceable ceramic heating element. For temperature control these heaters are available with an integrated temperature monitoring system. These devices are available in various material grades. The electric cartridge heating element type 93./..EEx….T.(.) is designed for the heating of liquids in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 2014/68/EU) Art. 4, Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL Further information about our CSN® ExCartridge Heater

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN®cartridge type heating elements and bath heaters are eminently suitable for direct heating and warming of liquids of all kinds. Corresponding to the nature of the different media protective coverings of steel, various special steel types or porcelain can be selected. The electric heating inserts of CSN®cartridge type heating elements may be installed or dismounted without the necessity of draining the liquids from the container. The CSN®cartridge type heating elements and bath heaters are manufactured for nominal voltages from 110 up to 690 volts D.C. and A.C. In the case of higher heating capacities 3 or more elements each, being individually divisible by the factor 3 can be star or delta connected to 230 and 400 volts A.C. threephase mains. At 12 kW and a related length the elements are fabricated for 400 volts A.C. threephase delta connections. In any case the desired voltage and type of current has to be stated.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Cartridge Heaters by Maxiwatt is characterised by its flexibility in the production of exclusive orders for its customers, adapting all its manufacturing processes in order to obtain better productivity and efficiency when delivering orders in short periods of time. We do not use these 4 types of materials: Tantalum, Tin, Gold and Tungsten. If you would like to place an order or make a customised enquiry, please fill in the Customised Heaters form and we will contact you once we have analysed your needs.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

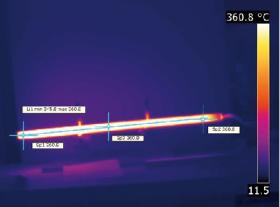

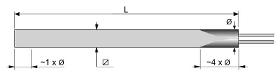

Uses in plastic industry: The infrared technic thermography can be used in plastic industries to optimize the process and improvement of quality, as well as in the development of new tools. In the thermoplastic injection process, can be found wide information about the transformation process itself:

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Maxiwatt High Load cartridges, which have been have proven themselves for 50 years successfully performing in thousands of applications applications that very few manufacturers are currently manufacturers are currently capable of producing, have a maximum temperature of 1000º.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Cartridges with high watt density. They provide a great uniform distribution of heat, and are hermetically manufactured, which considerably increases the long life of the resistance as well as preventing the oxidation of the heating wire even at high temperatures. Over 25.000 measurements in high density cartridges available. High density Maxiwatt cartridges are manufactured from prime quality materials and undergoing the strictest safety controls, according with international standards. -Long-life -High temperatures -Maximum watts capacity 60w/cm2

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

They are especially designed for quick adaptation in molds or surfaces where the use of rivets either causes problems or impossibility to use. Cuadrawatt cartridges are the better choice. Cartridges with a low density of watts are most recommended for moderate heating up to a maximum temperatures of 300ºC. The square tube is made of prime quality stainless steel. All the tubes are perfectly calibrated both inside and outside, into which a long-life ceramic piece is inserted. The tube resists a continuous temperature variation and has the best possible thermal conductivity, as the ceramic piece is in contact with the wall of the tube, which makes the most perfect heat distribution possible. Special Cold Sections: Distributed Wattage Single Circuit Element Independent Heat Zones Three Phase Element Dual Voltage Designs Thermocouple A,B,C RTD Elements Thermostats

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

The exclusive manufacturing design guarantees a precise temperature distribution throughout the plastic filament, melting it all at the same time. Only the thread of the nozzle is heated, where the casting process has to be produced. We only produce Cylinder Heater Core with different volts, watts and control systems, we do not include hot ends.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

The expandable cartridge Heaters solve two major problems with conventional high density heaters , poor durability and proper fit extraction improving the accuracy of the temperature with hundreds of attachments and exits for all kind of processes . With the expandable cartridge heaters we join for the first time the best of the common cartridge heater with cartridge and an adaptive tuning quick and easy removal.

Request for a quote

CARTRIDGE HEATER BY MAXIWATT

United States

Durawatt Compressed Cartridge Heaters with S/S Block - 90º Exit Ref. "T9" Water resistant and robust. Ready for removal from its bore housing. With tensile strength which prevents deformation in case of displacement of the shape. The finish T9 can be used in any hostile situation (high temperatures, waste material).

Request for a quote

CALDOR INDUSTRIAL HEATING SYSTEMS SRL

Romania

Introducing Caldor's Cartridge Heaters, the ultimate high-performance heating solution designed for a wide range of industrial applications. Our cartridge heaters deliver exceptional heat transfer, uniform temperatures, and long-lasting durability to meet the most demanding process requirements. Built with top-quality materials, Caldor's Cartridge Heaters feature a robust construction and high watt density, ensuring rapid heat-up times and excellent heat distribution. The innovative swaged design ensures superior heat transfer, while the built-in thermocouple ensures precise temperature control for consistent results. Key Features: Customizable dimensions to fit various applications Temperature range: up to 1400°F (760°C) Wattage: up to 200 watts per square inch Superior heat transfer and uniformity Long service life and reliable performance Easy installation and maintenance

Request for a quote

CRE VERZENI COMPANY

Italy

C.R.E. di Verzeni is a certified firm, leader in the production of heating elements for over 50 years. Our experience and skills allow us to establish not only in the Italian market, but also worldwide. Thanks to the purchasing of new machinery technology we have increased our quality standards while reducing production costs. This guarantees our clients, quality at competitive prices. We are official distributors for the main machinery manufacturers of: •Plastic, rubber (press, blow, extrusion, injection etc.) •Chemical/Pharmaceutical •Food (dryers and mixers) •Packaging •Water sector •Etc. C.R.E. di Verzeni is characterized by: One of the best quality on the European market--we got UNI EN ISO 9001-2000 certification Italian design with customized products Good quality/price ratio Fully made in ItalyProduction times: 7 days after your order and if urgent up to 24hours after the order (depends on the type of heater). On our website www.creverzeni.com

Request for a quote

FRIEDR. FREEK GMBH

Germany

Square cartridge heaters are used where much power has to be installed near the surface of a tool, e.g. in cutting knives, sealing stations or hot plates. With a soft, malleable condition in stainless steel or nickel sheath square cartridge heaters can easily be pressed into common milled rectangular grooves. Apart from the advantageous heat transfer over ¾ of the sheath, it is not necessary to cement or cast in the heater which is imperative for round cartridge heaters. Unlike tubular heaters which are also available in square sections (see chapter Flexible Heating Pipes), the square cartridge heaters have the termination on one side and can be loaded with 16W/cm² (2.5W/in²) due to their special inside construction.

Request for a quote

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Explosion protected high performance cartridge heaters for heating of liquids (oil and others), solid bodies or gas Plastics industry: hot runner systems, extruder heating Heating of metal pieces, such as moulds or tools. Heating of valves, nozzles or other parts of machinery Analysis technology Lube oil heaters for small machines.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Advantages of Heating Plates with Square Cartridge Heaters: -> Simple plate manufacture due to rectangular groove geometry, no deep-hole boring -> Simple heater installation by bending and pressing along the plate surface -> Complex plate geometries with bores and openings -> Optimal heat transfer due to 75% surface contact -> No casting with heat conductive compound -> Uniform temperature profiles due to thermally optimized groove layouts/power distribution and utilization of insulation plates -> high process temperatures (up to 450°C in aluminium, up to 700°C in stainless steel) Example "Heated Stamp": D=100 mm out of tempered tool steel up to max. 700°C continuous temperature. Fitted with 2 Square Cartridge Heaters 1500 W/ 230 V, 4,5 x 4,5 mm x 600 mm, with 50 mm unheated at the termination end. Annealed and formable with a nickel sheath, resistant up to 850°C surface temperature. Connection by fibreglass insulated pure nickel high-temperature leads (max. 500°C)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy needed by hot air fans and ignition blowers. Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Specification: Voltage: 120V/230V Power: 160 W, 180 W, 210 W, 225 W, 230 W, 240 W, 255 W Tube Size: OD10.5 × ID6.5 × L90 mm Supporting Socket: NO.4/NO.5/NO.6/NO.29 Lead wire: 300mm/400mm/500mm/900mm (Customized is accept) Range of temperature: 800~1100 °C Ceramic igniter technology benefits: A fraction of the energy consumption compared to conventional cartridge or element heater. Long-lasting (non-aging). Time to ignition 60~90 seconds. Tested to 100,000 cycles. Easy to install and retrofit. 800~1100°C at steady-state temperature. Impervious to oxidation and corrosion.

Request for a quoteResults for

Cartridge heaters - Import exportNumber of results

19 ProductsCompany type

Category