- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramic balls

Results for

Ceramic balls - Import export

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

NORELEM FRANCE

France

Ceramic bearings Si3N4. Bearing cage PTFE. For most applications Si3N4 is the preferred material for ceramic bearings. Silicon nitride bearings are light, very hard and highly wear resistant. High and ultrahigh performance bearings are used in e.g. aerospace technology, metal production industries (high application temperatures), machine manufacturing, chemical industries (chemically aggresive substances), pharmaceutical and medical industries, semiconductor and biotechnology (clean room enviroments which may not be contaminated by lubricants). On request Special version with PEEK ball cage. Without ball cage.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Balls are widely used on bearings with extreme performance requirements, such as: High-speed bearings, high precision bearings, vacuum bearing, high / low-temperature bearing, non-magnetic bearing, high precision ball screw; it is also used as valve ball, measuring ball for the chemical pump, heat pumps, metering pumps. Its excellent properties including: Good corrosion resistance withstands attacks from harsh chemicals and environments. High-Temperature Hardness is twice that of steel, Silicon nitride ceramic balls retain their strength and hardness up to 1800 degrees F.Lightweight, silicon nitride ceramic balls’ density is 3.20g/cm3 and weighs 45% less than steel which reduces centrifugal force, skidding and wear under high speed and acceleration, so greatly extending the service life. Superior Surface Finish is conducive to improving working speed and reach higher accuracy.

Request for a quote

IMETA SRL

Italy

Ceramic ball bearings are fully resistant to corrosion as both the external and internal races are made of stainless steel, while the inner cage is made of plastic material, which is resistant against high temperatures. Thanks to the low friction of the ceramic balls, the seaming rolls require a reduced lubrication – up to five times less than standards. This saves time for the operators and the machine downtime, allowing increased production.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ball Mill /Beads / Grinding Media is made of good material and used advanced technology, which is suitable for any kinds of mills such as sand mill, attrition-mill, vibratory mill, ball mill and so on. It is used to grind and disperse the material of painting, dye,ink, titanium, electronic battery material, rare-earth material, nonmetal ore, calcium, pesticide, food stuff and medicine etc..Because of its high density, toughness and hardness, zirconium grinding media’s efficiency is much better than traditional ones.The high wear-resistant zirconium grinding media can not only prevent materials from being contaminated, but also prevent chemical erosion that affects its working life Sizes Ømm of the Zirconia ball mill grinding media : - 0.2-3mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: - Ø0.5-3mm Grinding ball use in sand mill - Ø5-20mm Grinding ball use in mix mill and ball mill - OverØ20mm Grinding ball use in ball mill

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Ball is made of the hot isostatic pressing and sintering furnace and has the properties including high strength,high wear resistance,high temperature,corrosion,acid and alkali resistant,long-term using in the sea,good electrical insulating ect. The precision Si3N4 Ceramic Ball of Innnovacera produce is widely used in a a variety of high-precision, high-speed / ultra-high-speed bearings, vacuumbearing, high / low temperature bearing, non-magnetic bearing.It is also as the measurement ball used in chemical valve,high temperature valve,meter valve ect.The field of the application involve chemical, metallurgical, medical, food, oil, electronics,aerospace,ect. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The Zirconia Ceramic Ball mill jar is one part of all kinds of grinding and mixing materials equipment. During the various types of ball mill jars, horizontal and planetary ball mill equipment are mostly used. Now let’s explore the differences between these two types of ball mill equipment so that you can select the right equipment for related application. Planetary sand mill equipment A planetary ball mill is an efficient ball mill equipment, its grinding principle is the grinding tank as a planet, through the interaction of the planet and the grinding ball, the grinding ball in the tank’s high-speed movement, and friction and collision with the sample or abrasive, to achieve the purpose of grinding. Planetary ball mill is suitable for the preparation of high-purity materials cell crushing and other fields, its biggest advantage is that the grinding efficiency is high, and the grinding particle size is adjustable.

Request for a quote

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

MARTEAU & LEMARIE

France

Marteau & Lemarie ball specialists since 1922, selling all types of industrial balls on the market: Our company is renowned for the quality of its precision balls and also supplies polishing and grinding balls. Our different type of precision balls include: precision steel, stainless steel and plastic balls, and other precision balls (tungsten carbide, ceramic, glass, bronze and brass balls). Precision steel and stainless steel balls are defined by their nominal diameter, the raw material from which they are made and by their degree of precision. Grinding & polishing balls we stock mainly steel balls, stainless steel balls and glass balls. Our technical sales team is at your disposal for any further information and requests for quotes. So don't hesitate to contact us.

Request for a quote

MARTEAU & LEMARIE

France

Precision balls : Our precision balls range is huge. Balls are made from various raw materials: steel, stainless steel, tungsten carbide, plastic, ceramic and glass balls … Their applications are limitless.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Zirconium oxide-based ceramic beads type WIWOX® KM specially developed for shot peening and surface finishing. The high fracture toughness and surface smoothness of the ceramic beads allow the production of extremely smooth surfaces.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

"Ball bearings with a material combination of bearing steel (inner and outer rings) and ceramic (balls) are called ‘hybrid’ ball bearings. All GMN ball bearings can be supplied as hybrid ball bearings. The material characteristics of ceramic balls in hybrid ball bearings result in significant increases in machine performance (in comparison to ball bearings using steel balls), especially under critical conditions.

Request for a quote

NORELEM FRANCE

France

The combination of excellent material properties is a special feature of silicon nitride (Si3N4). These include high resiliance and stability, excellent wear properties and good chemical resistance.

Request for a quote

PFEIFFER VACUUM GMBH

Germany

turbomolecular vacuum pump, hybrid bearing, ceramic ball bearingCompact yet powerful turbopumps with pumping speeds of up to 67 l/s for N2 Product description * - Compact design for minimum footprint * - High pumping speed and maximum compression for all gases * - Integrated drive electronics, suitable for industrial environments - Protection class IP54 * - Semi S2 and UL/CSA certification * - Ideal for all standard applications * - Patented laser balancing™ technology * - Maximum reliability through monitoring of operating data

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina Ceramic Beads are used large quantity in the world, because of their excellent consistence and reliability. Products to these specifications are manufactured from very high quality chemical-porcelain clay materials, which has quite excellent stability, high mechanical strengthand resistance to thermal shock. This makes them all ideal choice for support of all types of catalyst.widely used for heat retention ,equilibration media,as ethylene dryers,High temperature Shift ,Low temperature shift,Ethylene cracking and drying.are widely utilized as the covering or supporting materials of the catalyst in the reactors and the packing in the columns in such varied areas as petroleum, chemical industry, chemical fertilizer, natural gas and suport or protect the active catalyst , which especially have the comparatively good mechanical strength. Feature: * Excellent abrasion resistance * High purity * Excellent corrosion resistance * Energy saving of grinding and dispersion

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features: 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to 1380°C).

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconium oxide jars 60 times the hardness of regular steel, highly wear-resistant and resistant to acid and solvents. The grinding jars are extensively applied to in the fields of Paint, Ink, Geology, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, Environmental Protection and so on. Each jar set includes grinding jar, jar lid, rubber sealing gasket and different sizes of mixed zirconium oxide grinding balls. Specification: .High cost-effective, low wear and long lifetime. .High specific gravity, high efficiency. .Highly wear resistant to acid and solvents. .Highly polished, smooth, easy to clean, low abrasion to the equipment. .High mechanical strength, good toughness, impact resistance, no broken beads. .Mainly used for lab planetary ball mill machines.

Request for a quote

MPS MICRO PRECISION SYSTEMS AG

Switzerland

MPS Microsystems is specialized in manufacturing high-precision, miniature linear bearings. We offer a comprehensive range of exceptionally smooth bearings with bore diameters from Ø 2 mm to Ø 6 mm. The balls of these precision bearings meet ‘Grade 3’, the highest quality defined by the ISO 3290/DIN 5401 standard. Combined with a cage and a high precision casing, they allow rapid positioning while reducing friction and eliminating the stick-slip effect. The standard version of MPS Microsystems linear bearings consists of a stainless steel bushing and balls, and a brass cage. An all-stainless steel version or one with ceramic balls can be made on request.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic jars are used whenever small quantity of samples needed to be grinded. Each jar set includes grinding jar, lid, rubber sealing gasket and different sizes of mixed alumina ceramic grinding balls. It is best container for grinding rare earth materials, precious metals, medium and low ceramic capacitors, NTC, PTC piezoelectric ceramic and lithium We can customize various types of vacuum jar according to customer's needs. Physical Parameters: Composition: Al2O3 ≥ 99% Specific Gravity: ≥3.8 g/cm³ Hardness: 9 Mho’s Bending Strength : > 350 Mpa Water Absorption Rate: ≤0.005%

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

made from steel with carbide or ceramic insert with balls from steel, carbide, ruby, sapphire, plastic or ceramic

Request for a quote

TEKNIK MAKINA

Turkey

Ball Mill Dimensions: Labratuar φ90×150 Cm φ120×150 Cm φ120×300 Cm φ150×150 Cm φ150×300 Cm φ200×150 Cm φ200×300 Cm

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

We offer a line of ceramic bearings upone request. are made of ceramic in rolling elements and rings, and are characterised by a particularly large pressure range and temperature range of -250°C to +1000°C Bearings are current insulated no lubrication required

Request for a quote

EISELE GMBH

Germany

— Whitworth pipe thread — Chambered O-ring — Sealing NBR, FKM — Material brass nickel-plated — Temperature range 32 to 122 °F (0 to +50 °C) — Working pressure range -13 to 218 psi (-0,9 to 15 bar) — Speed 800 rpm — Hybrid stainless steel ball bearing with ceramic balls

Request for a quote

EISELE GMBH

Germany

— Whitworth pipe thread — Chambered O-ring — Sealing NBR, FKM — Material brass nickel-plated — Temperature range 32 to 122 °F (0 to +50 °C) — Working pressure range -13 to 218 psi (-0,9 to 15 bar) — Speed 800 rpm — Hybrid stainless steel ball bearing with ceramic balls

Request for a quote

FISCHER FORTUNA GMBH

Germany

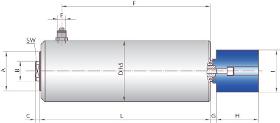

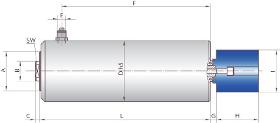

with hybrid spindle bearings and lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN842 in the web shop.

Request for a quote

FISCHER FORTUNA GMBH

Germany

with hybrid spindle bearings with lifetime grease lubrication. Hybrid bearings with steelrings and ceramic balls ensure high lifetime and speed. The spindle is maintenance-free and requires no external service unit. The spindle nose air labyrinth seal reliably protects the bearings against the ingress of contamination and coolant. Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories for the HJN828 in the web shop.

Request for a quoteResults for

Ceramic balls - Import exportNumber of results

34 ProductsCategory

- Ceramics (9)

- Ceramics, industrial (8)

- Precision balls (7)

- Bearings, ball (5)

- Bearings - ball, needle and roller (2)

- Bearings, roller (2)

- Connectors, plumbing (2)

- Balls (1)

- Ceramics, refractory (1)

- Mining and quarrying - machinery and equipment (1)

- Precious and semiprecious stones and pearls (1)

- Pumps (1)

- SMALL METAL PARTS (1)

- Screws (1)

- Vacuum pumps (1)