- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- compressor

Results for

Compressor - Import export

PEEKCHINA CO., LTD.

China

Manufacturing Process CNC Machining & Injection Molding PEEK performance Polyetheretherketone (PEEK) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties. These properties range from high temperature performance to mechanical strength and excellent chemical resistance. Material Grade ARKPEEK-1000: 100%PEEK Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types. ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values. ARKPEEK-GF30: 30% glass fiber + 70% PEEK Glass filled PEEK exhibits increased mechanical strength and high rigidity. ARKPEEK-MOD: 10% Carbon Fiber + 10% PTFE +10% Graphite high performance engineering plastic with product characteristics including excellent sliding and abrasion & wear resistance, high mechanical.

Request for a quote

LUOYANG SUNRUI SPECIAL EQUIPMENT CO., LTD.

China

High pressure expansion joint of Polyethylene, polypropylene compressor piping

Request for a quote

SHANGHAI XIAYU INTERNATIONAL TRADING CO.,LTD.

China

Generator: HP:3 KW: 4 Storage Volume:130L Cylinder(Diameter×No(mm)):70x260*1mm Exhaust Volume:300L/min Rating Pressure:12.5BAR Heaviness:158KG Dimenstion:136x50x100(cm)

Request for a quote

WENZHOU DONGYI MACHINERY MANUFACTURING CO,.LTD

China

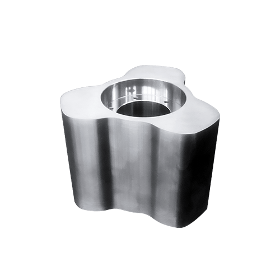

FOR A WIDE RANGE OF OPERATING CONDITIONS Our factory manufacture to the highest quality standards a full range of pistons and piston rods in stainless or alloy steels, aluminum and cast iron, for a broad range of applications and operating conditions. Experienced technical knowledge of compressor design and operation ensures that the optimum materials, surface treatments and sealing components are selected for each application. FEA analysis is used to ensure the design meets all of the highest engineered standards to guarantee product integrity and quality. Piston and Rod Reconditioning All pistons and rods are inspected to assess how to proceed with reconditioning and to ensure their suitability for re-use. Piston reconditioning may include re-machining of grooves and re-anodizing. Rod reconditioning may include machining, grinding, polishing and the application of specialized spray coatings. Finally, all parts are re-assembled including piston and rider rings.

Request for a quote

WENZHOU DONGYI MACHINERY MANUFACTURING CO,.LTD

China

1.Multimedia Grooves ——— Large flow area, low loss of the valve 2. The double damping design ——— low impact when opening and closing 3. The tilt motion of the valve is low ——— low impact speed, long life 4. Strong buffer spring ——— resistance to oil viscosity 5. Soil Resistance ———— Resistance to liquid and impurities and oil viscosity, high reliability

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Compressor - Import exportNumber of results

6 ProductsCountries

Company type