- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- melting

Results for

Melting - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish Hot melt OPP glue labeling machine is widely used for different material of container . The label cost is comparatively lower, it can meet the requirements of those users who have diverse kinds of the containers. It is the most economical models in cost to make mass production and intergrated operating. The equipment has massively used modularization design concept to make it easy and simple for users to change the bottles. Whether from the replacement of star wheel, guide plate or manual speed adjustment to automatic speed control, for example changing the label is only needed to change the program, the products concept of that the equipment is designed for users is embodied in everywhere.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

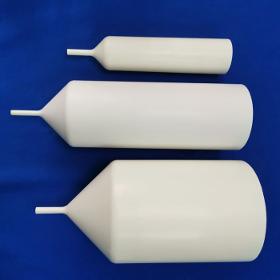

The crucible is produced by depositing pyrolytic boron nitride upon a mandrel having the shape of the desired crucible at a temperature of from about 1850° C. to about 2100° C. until a first layer of boron nitride of suitable thickness has been produced, interrupting the deposition of boron nitride upon the mandrel and lowering the temperature to below 1750° C., and then depositing additional boron nitride upon the mandrel at a temperature of from about 1850° C. to about 2100° C. to produce a second outer layer of boron nitride having a thickness greater than that of the inner layer. Features and Benefits of Boron Nitride ceramic 1. Easily Machinable 2. Exceptional Heat Resistance 3. High Thermal Conductivity 4. Low Thermal Expansion, Excellent Thermal Shock Resistance 5. Outstanding Electrical Insulation - even at high temperatures 6. High wet resistance to molten metals, slags and glass 7. Extreme Corrosion and Wear Resistance

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Industrial alumina ceramic square crucible is used for testing laboratory and a variety of industrial analysis.We can supply 99% and 99.5% alumina ceramic crucible and zirocnia ceramic crucible according to customer's drawings, samples and performance requirement. Alumina ceramic crucibles include: 1.arc alumina crucible 2.square alumina crucible 3.rectangle alumina ceramic crucible 4.columnceramic crucible 5.other shaped alumina ceramic crucible Overview of Physical Properties: 1. High chemical etching resistance. 2. High temperature up to 1800°C(Alumina) and 2400°C(Zirconia) 3. Resistant to sudden cold and hot, un-explosive. 4. High density of slip casting.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to anisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Pyrolytic boron nitride is a grade of hexagonal boron nitride. It is produced by chemical vapor deposition process to create its solid body and all the boron nitride crystals grow parallel to the surface of which the vapor is deposited on. Due to the nature of CVD process, PBN parts generally are requested the wall thickness not more than 3mm. PBN is also a good choice for extremely high purity of boron nitride. 99.99% is the typical grade. The CVD process give this pyrolytic boron nitride almost perfect layered structure, which leads to nisotropic thermal conductivity, making it an ideal material to make crucibles for crystal growing. PBN Ceramic Applications: -Crystal growth (VGF, LEC Crucible) -Molecular Beam Epitaxy(MBE) Crucible -MOCVD Heater -PBN Infrared Window -Traveling Wave Tube (TWT) (PBN Support Rod) -PBN Coating Graphite -High temperature, vacuum equipment insulator

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic crucible is the use of high purity powder, trace elements added, from the phase structure and microstructure of modified production.A smelting vessel. Products are aluminum oxide crucible and fully stabilized zirconia porous crucible, the former is mainly used for smelting and laboratory Firing other high melting point material, which is mainly used for the melting temperature with Pt,Rh, Au and other precious metal. Series: •Alumina ceramic crucible •Zirconia ceramic crucible •Conical or curved alumina ceramic crucibles •Cylindrical alumina ceramic crucibles •Rectangular crucibles •Special shaped crucibles •Alumina saggers Alumina ceramic crucible specifications: 5ml 10ml 15ml 20ml 25ml 30ml 50ml 100ml 150ml 200ml 250ml.

Request for a quoteResults for

Melting - Import exportNumber of results

7 ProductsCountries

Company type