- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pistons

Results for

Pistons - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The piston filler is one of the main product of Npack, most of Npack liquid filling dispenser are applying in the fields of Daily chemicals, cosmetics, Food&beverage,personal care products, pharmaceuticals, Oils products.As piston filling machine are solely based on conventional volumetric technology, these are easy to operate and relatively low cost for the majority of the end-use industries. Piston filling machine is one of the most popular liquid filling machine for its universal ability ,piston filling machine can fill thick and highly viscous products, such as chunky, semi-paste, paste products, also extensively utilized to fill chemical preparations, such as adhesives, greases, epoxies, waxes, and lubricant oils, also an optional for filling thin liquid Widely application of liquids, such as viscous liquid, shampoo, lotion,cream;Food sauce;foamy liquid,hand liquid soap,detergent. High Performance and accuracy,easy operation.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

One of the most significant advantages of an automatic piston filling machine is that it reduces labour costs and increases production speed. The machine can handle a high volume of products, which can help to reduce manufacturing costs in the long term. Furthermore, as the machine is fully automated, it minimises the risk of human error, which further increases production efficiency. Model Recommended: NP-VF 12 Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Reasonable Design: Designed with a high-quality filling head Easy to Operate: Add the filling material to the hopper, adjust the filling volume, then use the handle switch to control and finish the filling. Standard filling nozzles with OD4MM and OD8 mm, suitable for most of the products specification. Comfortable handle which helps improve user more easy operation The filling volume is adjustable by a mechnical screw, easier and faster Parameters The filling system is piston volumetric and are operated by manual ,efficiently accurate filling with high speed. Filling speed: 10-50 times/min Filling Volume: 5ml to 50ml Hopper capacity: 10L Net weight: 10KG 304SS construction

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life. Dense material, water absorption as low as zero; very high surface finish, minimal friction; therefore minimal residual materials. Thermal expansion coefficient is small, piston clearance fit more, filling accuracy can be achieved online cleaning and sterilization.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

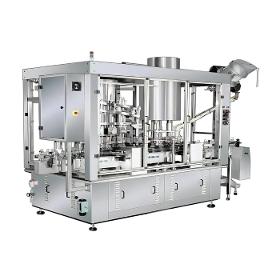

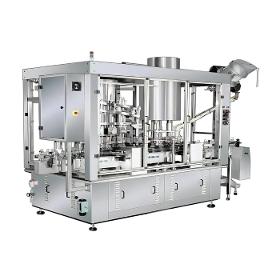

An automatic rotary piston filling machine is a type of volumetric liquid filling machine used to fill liquids into bottles, jars, or containers at high speeds. It operates by using a rotary motion to move the containers through a series of stations, where each station performs a specific function in the filling process. The filling process involves filling the liquid into the containers accurately and precisely using a piston mechanism that is driven by a rotary motion. The liquid is metered out using the piston, which moves in and out of a cylinder to fill the desired volume of liquid into the container. Once filled, the containers are then moved to other stations to complete the filling process. Some of the benefits of using an automatic rotary piston filling machine include increased efficiency, accuracy, and speed, as well as reduced labor costs and waste. These machines can be used for a wide range of liquid products

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machines are made of high-quality stainless steel, making them durable and easy to clean. 6. Automatic control: Liquid weighing filling machines have automatic controls that detect when the container is full, stopping the filling process. 7.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The inline piston liquid filling machine is more flexiable, and suitable for a wide range of container size range from 100ml to 5000ml.It is has advantage of high filling speed, high accuracy and easy adjustment for different types of containers. Application It is application for any viscous liquid to thin liquid which is non corrosive the stanless steel, Piston filling machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and consistent dosing is important. They can handle a wide range of products with varying viscosities, from thin liquids to pastes and creams

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The NP-EVF economy automatic horizontal piston filler is equipment with 2 or 4 filling heads,the driven system can be air cylinder or a servo motor. Feature 1.Accurate and precise weighing: These machines use load cells or scales to ensure the accurate measurement of the liquid being filled. The measurements can be in grams, ounces or liters, depending on the application. 2. Easy to set-up and use: Liquid weighing filling machines can be programmed for different weight ranges and filling speeds. They also come with user-friendly touchscreen interfaces for easy operation. 3. Versatile: These machines can fill a wide range of liquid products, such as water, milk, oil, chemicals, and pharmaceuticals. 4. Fast filling speed: They can fill several bottles or containers per minute, increasing productivity and reducing downtime. 5. High-quality construction: These machi machines are made of high-quality stainless steel, making them durable and easy to clean.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic pump performance characteristics: (1).Extremely inert chemical stability, acid and alkali resistance, corrosion resistance and high temperature resistance. (2).super hard, wear-resistant, particle release is very small, long service life. (3).the material is dense, the water absorption rate is lower than zero; the surface finish is extremely high, the friction is extremely small; the material residue is extremely small. (4).the coefficient of thermal expansion is very small, the piston fits better,the filling machine has higher precision, and can be cleaned and sterilized online. Filling range and advantages: (1).According to different filling ranges, a variety of pump head specifications are available. (2).reasonable structure layout, easy to disassemble, easy to clean, more convenient and convenient in maintenance and maintenance;

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machines. We can make customized shapes and sizes of the ceramic filling pump according to clients’ design requests. This kind of ceramic piston and plunger is widely used for Lithium battery single head/double head /four head electrolyte liquid filling machines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA is a professional manufacturer of ceramic metering pump. The material we made for ceramic plunger pump is 99% alumina and zirconia, made by CIP forming and then with precision processing.Our business expanding in high-tech filling solutions for precision liquid filling in 2015, offer high grade accuracy, precision and durability. They are utilized in a broad range of Medical, Laboratory, Analytical and Industrial Process applications. All our ceramic filling pump products are Food Grade. There are three types of pump modules: Rotary, Linear and Multiplex which are used for different applications depending upon the customer's fluidic needs.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machines. We can make customized shapes and sizes of the ceramic filling pump according to clients’ design requests. Product size for reference: Similar Series Products Min Filling Volume: 0.5 ml Similar Series Products Max Filling Volume: 1000 ml Filling accuracy : <=0.5% Product Application: Applicable in quantitative subpackage with high level of hygiene requirement like injection oral liquid etc. Widely applied to pharmaceutical equipment of famous enterprises BOSCH, B+S, IMA, GROENINGER, INOVA company and Trucking Technology, Miaxis, Qianshan, etc.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machine. We can make customized shape and size of ceramic filling pump according to clients design request. Product Application: Applicable in quantitative subpackage with high level of hygienerequirement like injection oral liquid etc. Widely applied to pharmaceutical equipments of famous enterprises BOSCH, B+S, IMA, GROENINGER, INOVA company and Trucking Technology, Miaxis, Qianshan etc. CERAMIC FILLING PUMP FEATURES: Liquid non-polluting, High precision Long service life, Very high surface finish High hardness, Wear resistant Particle release is extremely small Water absorption as low as zero Minimal friction, Minimal residual Low thermal expansion coefficient Inert Chemical stability, Acid corrosion resistance Resistant to high temperature, Piston clearance fit more Filling accuracy can be achieved online cleaning and sterilization

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

All of our products are customized by customer's drawing. Please feel free to send us your inquiry

Request for a quote

PJM MECHANICAL CO.,LTD

China

Light Duty 225lb 2"/6"/8"/10"/12" Stroke Electric Linear Actuator Motor DC12V.The electric piston actuator is designed with a screw piston and nut by the dc motor motion.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PEEKCHINA CO., LTD.

China

Manufacturing Process PEEK CNC Machining & Injection Molding PEEK Back Up Rings Elevate your sealing systems to new heights with PEEK back up rings. Crafted from high-performance polyetheretherketone (PEEK) material, these rings offer exceptional durability and chemical resistance, ensuring long-term reliability in even the harshest environments. With precise engineering and tight tolerances, PEEK back up rings provide optimal support to prevent extrusion and maintain seal integrity. Explore their versatility and unleash the full potential of your sealing applications today.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

An automatic detergent piston filling machine is a piece of equipment that is used to fill detergent products into bottles or containers. This machine operates by using a piston that pulls the product from a holding tank and then dispenses it into the containers. The process is automated, which means that the machine can fill a large number of containers quickly and efficiently. Feature: Nozzles Servo Piston VolumetricFilling Machine Filling Range: 0.5L- 5L adjustable on touch screen. Bottle Mouth: according to samples Driven and controlled system: Double Panasonic servo motor, one servo motor driven 6 pistons, TBI high precision screw lead, high precision piston. Accuracy: <+/-0.5% Capacity: 3000BPH for 2L Hopper: automatic liquid feeding system Container: suitable for 0.5-2L Plastic bottles Voltage: 220VAC 50/60Hz Power: 2000W Drop-proof filling nozzles: adapting vacuum sucking nozzles. Touch Screen Language: English and Chinese

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Manual Liquid Piston Filling Machine is suitable for filling small dose viscous liquid , it is adjustable for Cream,sauce,cosmetic Filling, operation by manual power. Filling range from 5ml to 120ml. Feature Reasonable Design: Designed with a high-quality filling head Easy to Operate: Add the filling material to the hopper, adjust the filling volume, then use the handle switch to control and finish the filling. Standard filling nozzles with OD4MM and OD8 mm, suitable for most of the products specification. Comfortable handle which helps improve user more easy operation The filling volume is adjustable by a mechnical screw, easier and faster

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Semi automatic Pneumatic volumetric Piston Filling machine is available with Single Head or double filling Heads.High quality and famous brand air cylinder ensure the machine work stably and fast.Make the machine suitable for fill viscosity and liquid.This semi-auto machine have 2 working mode for operation,auto and pedal. Feature Volumetric by a high quality piston High accuracy measurement system for different types of non corrosive liquid liquid contact parts 304SS or 316SS depends on the liquid filling volume is easy adjustable, and by the distance of the piston working stroke The Filling nozzles can be shut off, anti drops the filling valve can be single direction for thin liquid and butterfly valve for viscous products the top tank is for optional, and can be with mixing and heating function if need. Pharmaceutical, GMP,FDA health standards. Hard, abrasion resistant, particle release is extremely small, long service life.

Request for a quote

PJM MECHANICAL CO.,LTD

China

12V light electric linear actuators were designed for applications where space is limited and lighter loads are used. The 12V power is often derived from a battery. So 12 volt linear actuators are more easy to use on automobile machines and off-highway vehicles automation. With extensive experience in several engineering projects towards actuator miniaturization, we can easily design the small linear actuator type. At the same time, we can also focus on providing general improvements on mechanical efficiency, speed, or load capacity.

Request for a quote

PJM MECHANICAL CO.,LTD

China

The electromagnetic linear actuator is designed with magnet motor( brush motor) shaft, gearbox, nut integrated.12v electromagnetic linear actuator and 24v electromagnetic linear actuator are available.

Request for a quote

HONGYU METAL PRODUCTS (GUANGZHOU) CO., LTD

China

Product name: Piston rod Application: Shock absorber Out Diameter: 6mm-60mm Length: 30-1000mm Surface treatment: Chrome plating. Roughness : Ra 0.1 Micron Max Straightness : 0.02-/400mm Chrome Hardness : 900 HV Min Chrome Thickness :10-25um

Request for a quote

HONGYU METAL PRODUCTS (GUANGZHOU) CO., LTD

China

Product name: Piston rod Application: Shock absorber Out Diameter: 6mm-60mm Length: 30-1000mm Surface treatment: Chrome plating. Roughness : Ra 0.1 Micron Max Straightness : 0.02-/400mm Chrome Hardness : 900 HV Min Chrome Thickness :10-25um

Request for a quote

HONGYU METAL PRODUCTS (GUANGZHOU) CO., LTD

China

Product name: Piston rod Application: Shock absorber Out Diameter: 6mm-60mm Length: 30-1000mm Surface treatment: Chrome plating. Roughness : Ra 0.1 Micron Max Straightness : 0.02-/400mm Chrome Hardness : 900 HV Min Chrome Thickness :10-25um

Request for a quote

HONGYU METAL PRODUCTS (GUANGZHOU) CO., LTD

China

Product name: Piston rod Application: Shock absorber Out Diameter: 6mm-60mm Length: 30-1000mm Surface treatment: Chrome plating. Roughness : Ra 0.1 Micron Max Straightness : 0.02-/400mm Chrome Hardness : 900 HV Min Chrome Thickness :10-25um

Request for a quoteResults for

Pistons - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Bottling and filling - machinery and equipment (13)

- Wheels, castors and rollers - metal (10)

- Ceramics, industrial (5)

- Milling - steels and metals (2)

- Piston pumps (1)

- Piston rings (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Electric motors - dC (1)

- Electrical equipment, ships (1)

- Polishing - machine tools (1)