- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- control valve maintenance

Results for

Control valve maintenance - Import export

SDT ULTRASOUND SOLUTIONS

Belgium

TRAPChecker is an ultrasound solution designed to assess the condition of steam traps and valves. Focused Inefficient steam systems waste energy and impact product quality. TRAPChecker is an ultrasound solution focused on finding failed steam traps. It works on every style of trap and failure mode. Simple TRAPChecker is so easy to use. Simply open the box, connect the sensor, and hear the difference between a good and bad steam trap. Its vibrant colour display offers repeatable, accurate, digital measurements. Affordable As much as 40% of your steam traps could be operating in a failed state. The low entry cost of TRAPChecker and the high cost of energy, could see your investment recovered the first time you use it. The TRAPChecker detects internal turbulence by defective steam traps and passing valves. Designed to work with SDT’s RS2 Needle Contact Sensor.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

In contrast to other valve designs, only two diaphragm valve components come into contact with the operating media the diaphragm itself and the valve housing. The long service life, reliability, safety and resistance against aggressive and abrasive media, combined with the excellent control quality of the directly mounted digital positioner result in an ideal control valve with minimal maintenance effort and low operating costs. With its pneumatic actuator and proven Schubert & Salzer positioner, the diaphragm valve 7069 equipped with plastic housing is not only a true control valve alternative for applications in the fields of chemistry, cosmetics, environmental engineering and water treatment, it is also ideal for galvanising technology as well as for the food and beverage industry. A true all rounder.

Request for a quote

THOMSON MACHINERY BV

Netherlands

High powered and fuel efficient • - Virtually maintenance-free oil-cooled disc brakes or Shoe brakes • - 2 Speed powershift Transmission • - Lift and Tilt Locking Hydraulic Control Valve • - Enhanced maintenance and Serviceability • - OSS(Operator Sensing System) o - No truck moving with an operator’s absence on driver seat o - Hydraulic lifting and lowering o - Parking Brake warning o - Seat Belt Indicator • - Available Emission Regulation o - Diesel : EPA Tier Ⅱ, Ⅲ / EU Stage Ⅱ, ⅢA

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The multiple water quantity control system in modular design that is available in several versions fulfils not less than three requirements at the same time. It combines the advantages of the conventional water distributors, the impulse cooling systems and the continuously operating temperature control units while eliminating the disadvantages of each of these systems. The temperature control system disposes of up to 128 individually adjustable circuits and is suitable for the processing of polyolefins and technical thermoplastic materials. In case of the basic execution (itd B) the requested flow rate is adjusted manually and is then monitored by a flow meter and presented digitally and graphically on the central display of the control unit. In the standard execution (itd R) the water quantity is individually set for each circuit at the central operating unit and - if necessary - is readjusted automatically via a water quantity regulation valve within adjustable limit values.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Brake force control valve for stepless regulation of the brake pressure.

Request for a quote

MÜLLER CO-AX GMBH

Germany

Within the family of pressureregulating valves, a technical distinction is made between series of bypass valves, inline valves and threeway valves.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The pneumatic sliding gate control valve type 8028 in reinforced GS3 design with integrated positioner and with an 80 mm diaphragm actuator is ideal for compact plant installations in process technology. In addition to the compact design, this valve is characterised by high control precision and a long service life. Digital positioner type 8049 Positioner type 8049 in explosionproof version Positioner with integrated process controller type 8049 IPC Metal bellows Limit switch Position feedback Pilot valve . . .

Request for a quote

MÜLLER CO-AX GMBH

Germany

This series comprises valves with two connections that are operated by an electric motor. They are characterized by the fact that the valve stroke can be adjusted steplessly and held in place by a motor using a setpoint signal (420 mA or 010 V). This makes this series particularly suitable for precise dosing applications, as the servo motor reliably processes setpoint deviations of 1%.

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hightemperature sliding gate control valve type 8024 in reinforced GS3 design with integrated positioner is suitable for a wide range of process applications up to 530°C. Media such as steam, liquids, gases, etc. can be precisely controlled even in the hightemperature range. Digital positioner type 8049 Pneumatic and electropneumatic positioner type 8047 Positioner with integrated process controller type 8049 IPC Positioner type 8047 and type 8049 also in explosionproof version Positioner with mounting acc. to NAMUR standard Metal bellows Limit switch Position feedback Manual override Pilot valve . . .

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

The hygienic angle seat control valve type 7025 with integrated digital positioner is specially adapted for use in the food and beverages production. Suitable for controlling product streams, drinking water, CO2, nitrogen as well as sterile steam and sterile air. All wetted plastics are FDA-compliant and conform to EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. The hygienic angle seat valve is also certified to Technical Instructions on Air Quality Control (TA-Luft) in accordance to ISO 15848-1 and on request can be supplied with an acceptance test certificate in accordance with EN10204 3.1.

Request for a quote

TECNIDRO

Italy

The valve closes totally the pipe line when back flow occurs. The valve is complete with an hydraulic control circuit able to regulate operation’s speed during closing, preventing surge.

Request for a quote

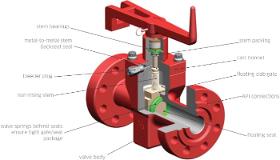

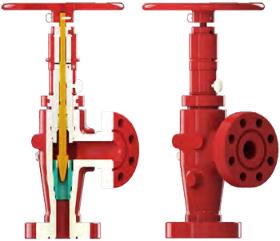

TETHYS OIL SUPPLIES & SERVICES

Malta

Designed to boost your well economics, our gate valves meet API PR2 Annex F operational requirements and are built to withstand the harshest onshore production environments. Leveraging on more than 20 years of field experience with the standard Series100 valves, TechnipFMC’s M120plus gate valve design is developed over 4 years of extensive research and development. Detailed finite element analysis led to development of a lighter, more open valve body which enables better access to the seat pockets for easier, quicker assembly and maintenance. TechnipFMC individually qualifies each gate valve size using nitrogen gas even though API Spec 6A permits qualification by scaling one size above and one size below the tested valve. In addition, TechnipFMC imposes additional performance requirements and endurance testing to simulate 25 years of operation in the field. Also available in “adapted for actuator” configuration for M130Plus model.

Request for a quote

TETHYS OIL SUPPLIES & SERVICES

Malta

The 200 Series choke valves are the result of our continued commitment to product research and development in the oil and gas industry. We have a proven track record of delivering technical solutions for our customer base stretching back decades. The 200 Series has evolved from years of product experience and incorporates the latest in material and manufacturing techniques. Each choke valve is designed, manufactured and tested in accordance with API 6A and can be fabricated to various material classes and product specification level. A wide variety of product configurations are available to meet every client need.

Request for a quote

ALPECO LIMITED

United Kingdom

Flow control valves regulate the flow or pressure of a fluid. Control valves normally respond to signals generated by independent devices such as flow meters or temperature gauges. Alpeco stock a range of Perrett hydrovalves and is the UK distributor for OCV Control Valves, who are leaders in control valves, check valves and pressure relief valves. Our flow control valves can be used across a wide range of fluids from fuel, oil and lubricants to paints, chemicals, water and cement.

Request for a quote

ALPECO LTD

United Kingdom

Alpeco is the UK distributor of OCV control valves. These valves can be found in Waterworks, Fire Protection, Irrigation, Industrial, Petroleum and Aviation fueling in nearly every country throughout the world. The range of models available is extensive and includes pump control valves, pressure relief and safety valves, high level shut-off valves and flow control valves.

Request for a quote

HYDROSILA

Ukraine

Design features: - cast iron body; - built-in check valve and adjustable relief valve; - the chrome-plated spool; - pneumatic control.

Request for a quote

HYDROSILA

Ukraine

Directional control valves series MRS120 are universal control valves of a wide application. Control valves series MRS120 are intended for use on excavators, cranes, loaders, trucks, drilling machines and other equipment. The auxiliary valves (anticavitation, shockproof, combined) are available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EISELE GMBH

Germany

- Whitworth pipe thread - Thread G2 for manual override - Chambered O-ring - Sealing: NBR - Material: brass nickel plated, Al black anodized - Allowable medium: air - Temperature range 14 to 158 °F (-10 to +70 °C) - Working pressure range 14,5 to 145 psi (1 to 10 bar) - Nominal flow rate measured when throttle is open at 87 psi (6 bar) and 14,5 psi (1 bar) pressure drop between inlet and exhaust

Request for a quoteResults for

Control valve maintenance - Import exportNumber of results

19 ProductsCountries

Category

- Valves for industrial fittings (6)

- Valves for pneumatic equipment (3)

- Construction - Machines & Equipment (2)

- Oil - drilling and extraction (2)

- Industrial valves, operating equipment (1)

- Paper - Printing - Machines & Equipment (1)

- Plastics - industrial machinery and equipment (1)

- Plastics - machines and material for industry (1)

- Pressure regulators (1)

- Ultrasonic measuring equipment (1)