- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor systems

Results for

Conveyor systems - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Applications and projects : conveyor systems assembly lines robotic units screwing welding Poka-Yoke vision Pick and Place Some practical examples : roll-forming machine conveyor system with elevator assembly lines for plastic and metal components ergonomic workstation on assembly line unit for recovery, transfer and removal of springs on assembly line

Request for a quote

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

FERPLAST SNC

Italy

IDLE ROLLER CONVEYORS EXTENSIBLE WITH METAL ROLLERS Roller conveyors extensible with metal rollers for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quote

FERPLAST SNC

Italy

It can be realized in economic manner and with reduced overall dimensions with roller conveyors curves up to 180 °. This type of roller conveyors are an economical solution to the problem of handling boxes and packs along 90 ° or 180 ° paths, avoiding the use of more expensive pneumatic diverters. The idle 90 ° curves can be combined to obtain 180 ° curves, and allow you to create packaging lines even in confined spaces, thanks to their small footprint. They have widths of 500-650-800 mm and can be equipped with metal wheels with a diameter of 48 mm, or metal rollers with a diameter of 32 or 48. The metal wheels, thanks to their particular smoothness, allow the advancement of the boxes also with a minimum inclination.

Request for a quote

FERPLAST SNC

Italy

Extendable roller conveyors with plastic wheels and galvanized steel pantograph structure for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quote

FERPLAST SNC

Italy

Roller conveyors extensible with metal rollers for handling boxes, cassettes and packages with a flat base. They are normally positioned at the outlet of packaging machines and taping machines for the accumulation of packages and allow to realize different forms of route with curves up to 180 ° (depends on the length of the roller conveyor). The roller conveyors are equipped with supports with wheels with brakes and they are easily extendable and resealable, they can thus be moved and stretched, taking up very little space when not used. The movement of the boxes occurs by gravity and the box stopper terminal (included) avoid the fall. The roller conveyors with width mm. 800 are equipped with central pantograph to make the structure more robust. Standard supports are adjustable in height from mm. 650 to mm. 900 but on request you can have supports with height mm. 450-650 (same cost) or mm. 950-1250 with increase.

Request for a quote

FERPLAST SNC

Italy

STANDARD MODELS WITH FREE ROLLER DIAM. MM 50 - PITCH MM. 75 FOR MEDIUM AND LARGE PACKAGES Roller conveyors consist of a sturdy structure profiled in painted steel, with supports legs fixable to the floor and adjustable in height, rollers in galvanized steel with rotation on shielded ball bearings. The roller conveyors are built according to the capacity and size of the boxes to be handled.

Request for a quote

FERPLAST SNC

Italy

STANDARD MODELS WITH FREE ROLLER DIAM. MM 32 - PITCH MM. 40 FOR SMALL PACKAGES Roller conveyors consist of a sturdy structure profiled in painted steel, with supports legs fixable to the floor and adjustable in height, rollers in galvanized steel with rotation on shielded ball bearings. The roller conveyors are built according to the capacity and size of the boxes to be handled.

Request for a quote

HO-MA GMBH

Germany

These can be designed for a wide variety of objects and applications for manual operation or as fully automated systems. In certain applications the combination of both types of solutions is also possible. Another possibility is a modular approach, which allows the customer to expand the capacities and the technical level later on according to his current needs. Individual stations can be connected by a conveyor belt system, or the parts can be transferred manually.

Request for a quote

FERPLAST SNC

Italy

MODEL RG - FREE ROLLER-COATED DIAMETER 32 MM - PITCH 40 MM FOR SMALL AND FRAGILE PACKAGES Free rollers conveyors that consist of sturdy painted steel 2 mm thick, 50x25 mm tubular support, legs fixable on floor and adjustable in height, 32 mm diameter steel rollers coated with rubber, rotating on ball bearings (8mm axle). The versions with a width of 1000 mm consist of a 2-roller axis with central support. This solution allows to have a greater flow rate that reaches up to 90 Kg/m.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

NOVELTY STEEL

Turkey

In a belt conveyor system, pulleys play a crucial role by altering the direction of the belt in a vertical plane. They create a continuous loop for uninterrupted operation. The pulley, also referred to as a drum, and its accompanying shaft combine to create a unified structure. Their operational features are interdependent. The evolution of conveyor pulley construction has advanced from fabricated wood to cast iron and, currently, steel fabrication. Pulleys are produced in various sizes, with the standard steel pulley being the most widely employed in conveyor systems.

Request for a quote

NOVELTY STEEL

Turkey

While various idlers have been developed to perform adequately in different installations, determining the most appropriate one remains a challenging task. The primary function of an idler roll is to provide load support with minimal resistance to movement, particularly addressing radial loading from the belt and materials across specific idler spacing. This role encompasses absorbing impact at the loading point and managing belt tension in curved sections, which can be challenging to quantify. Modern conveyor design methods have enhanced our comprehension and control, providing clearer insights into idler implications. Assemblies of idler rolls are strategically designed to influence the belt profile, often forming a trough or tube. It’s essential to acknowledge that the trough’s shape, consistency, and flexibility significantly impact idler roll behaviour.

Request for a quote

NOVELTY STEEL

Turkey

Belt conveyors used for handling bulk solids utilize rubber-covered belts, where the inner carcass of the belt provides the necessary strength to pull and support the conveyed load. The carcass is shielded from damage by layers of rubber, which may vary in thickness depending on the specific application. Belt conveyors exhibit the capability to transport materials across a broad range of rates, spanning from just a few kilograms per minute to several thousand metric tons per hour. ndard troughing angles are commonly set at 0°, 20°, 35°, and 45°. The angle of surcharge is a material-specific property and can be compared to the dynamic angle of repose. The power requirements for belt conveyors hinge on various variables, including the conveyor’s profile, the type of drive-pulley arrangement, belt tensions, belt speed, and idler spacing.

Request for a quote

GSW SCHWABE AG

Germany

with its compact design using a structural aluminum profile, conveyor system is ideally suited for continuous duty applications in multiple shift environments. using the benefits of modular construction, this conveyor can be readily integrated into new or existing equipment or be used as a freestanding conveyor for bulk handling and loading aplpications. inclination smoothly adjustable steplessly fourwheel drive, 2 steering wheels with parking brake 13 collector rollers, height 20 mm transport cover PUeven, 2 layers, to be used at temperatures from 30 120°C, oiland grease resistant, antistatic funnel (attachment), aluminium anodized drop area pivotable clip/aluminiumclosed bar system suitable for materials to be conveyed from a thickness of 2 mm on for lower thicknesses of materials to be conveyed, allaround corrugated material edges made from celloflex. This reduces the usable width of the material by approx. 70 mm

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automation solution to perform medical sample analysis in diagnostic laboratories. Automatic sample distribution system transports the samples directly to the appropriate analysis system

Request for a quote

HO-MA GMBH

Germany

1-lane infeed with distribution on 3 lanes for blow-fill products 3-lane infeed with distribution on 6 lanes for vial adapter products

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HO-MA GMBH

Germany

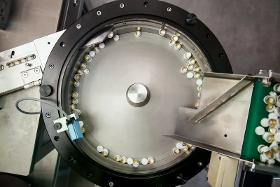

Centrifugal sorting is used for high capacities up to 800 pieces per minute. The quiet and gentle sorting is particularly suitable for plastic objects. Depending on object type and size we recommend different versions ZF-350, ZF-500, ZF-800. Due to the user-friendly and space-saving design, it can be combined with other machines and systems.

Request for a quote

HO-MA GMBH

Germany

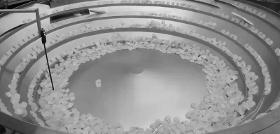

With vibration sorting, small batches / quantities can be processed individually up to 200 pieces per minute. Depending on the type of object, we recommend different designs / types – conical, cylindrical or stepped. Surfaces are preferably glass bead blasted or metaline coated (both variants have FDA approval). Mounting types are medium voltage and external voltage.

Request for a quote

HO-MA GMBH

Germany

Quick Visual Inspection mobile and compact design Detection of defects and contamination For: bottles / cans / vials

Request for a quote

HO-MA GMBH

Germany

Quick unpacking Mobile and compact design Tins For: vials / containers / trays

Request for a quote

HO-MA GMBH

Germany

Multitrack conveyor belt Different directions possible Buffering option with simultaneous discharge

Request for a quote

HO-MA GMBH

Germany

High volume Single track conveyor belt

Request for a quote

HO-MA GMBH

Germany

Increased output for further processing Tool-free format change Quick adjustment to product formats Selectable direction of rotation

Request for a quote

HO-MA GMBH

Germany

Instead of air, we make use of mechanics. Bottles can be unscrambled and positoned correctly by a simple wheel. You can benefit of reduced noice and low-energy consumption. High-capacity and qualified-for-cleanroom cabins make your choice right.

Request for a quote

HO-MA GMBH

Germany

The HO-MA bottle unscrambler positions bottles in the correct production position. The bottles are fed to the HO-MA bottle unscrambler as bulk material. By an interaction of sensors and pneumatics upside down bottles are detected and transported back to the sorting process. Sorted in the correct position, they are positioned by an individually adapted format part in such a way that they are directed onto a conveyor belt and smoothly integrated into the production process.

Request for a quote

HO-MA GMBH

Germany

Instead of air, we use pure mechanics. Bottles are turned and aligned with the help of a wheel. You benefit from low-noise and energy-saving processes. High performance and clean room suitability are convincing.

Request for a quote

HO-MA GMBH

Germany

The PRU is the gentle feeding solution for syringes. Round belts are used to separate syringes for further processing Gentle feeding system for syringes, with separating function

Request for a quote

HO-MA GMBH

Germany

With a reliable result of more than 80 percent and up to 99.9 percent, Naiopur is the new disinfection technology in the food industry. The previously customary swirling and vapour disinfection technology is replaced by a gentle feeding method and a 100 percent natural UV-C process. Valuable ingredients are conserved. Naiopur even allows you to disinfect products that you could only process using complex methods previously.

Request for a quoteResults for

Conveyor systems - Import exportNumber of results

364 ProductsCountries

Category

- Conveyor systems (179)

- Conveyor belts (60)

- Food industry - machinery and equipment (12)

- Storage equipment and systems (8)

- Bottling and filling - machinery and equipment (6)

- Goods handling systems, continuous (6)

- Motor mechanics - hand tools, non power (6)

- Automation - systems and equipment (5)

- Gears (4)

- Inductive sensors (4)

- Labelling machines (4)

- Plastics - machines and material for industry (4)

- Flour-milling (3)

- Laser - cutting and welding machines (3)

- Machine tools, metal shaping - parts and accessories (3)

- Conveyors, overhead and floor (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Foods, precooked and gourmet (2)

- Handling - Machines & Equipment (2)

- Machine tools, cutting - parts and accessories (2)